Electrolytic catalytic oxidation device and method for preparing 2,5-furandicarboxylic acid

A technology for electrolytic catalytic oxidation and furandicarboxylic acid, which is applied in electrolytic process, electrolytic components, electrolytic organic production, etc., can solve the problems of increasing production cost, reducing catalytic performance, low utilization rate of raw materials, etc., and achieves easy separation and good product purity. , the effect of low equipment and technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The preparation method of the monolithic electrode comprises the following steps:

[0069] S100, preparation of solution: CoCl 2 or CoSO 4 Add water to form a solution.

[0070] In the present application, there is no particular limitation on the concentration of the prepared solution. In order to prepare a monolithic self-assembled cobalt tetraoxide nanosheet catalyst with excellent performance, enhance its catalytic stability and prolong its service life, preferably, CoCl 2 or CoSO 4 The molar ratio with water is 1:500~1:1400.

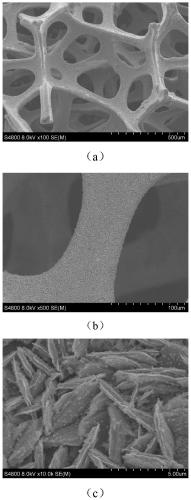

[0071] S200, hydrothermal reaction: put the solution obtained in step S100 in a reaction kettle, add nickel foam or nickel sheet or carbon paper or carbon fiber cloth and other substrates, keep warm at 120°C-180°C for 6h-24h, wash and dry get the precursor.

[0072] In step S200, there is no special limitation on the substrates such as nickel foam or nickel sheet or carbon paper or carbon fiber cloth to be added. In order to prepare a u...

Embodiment 1

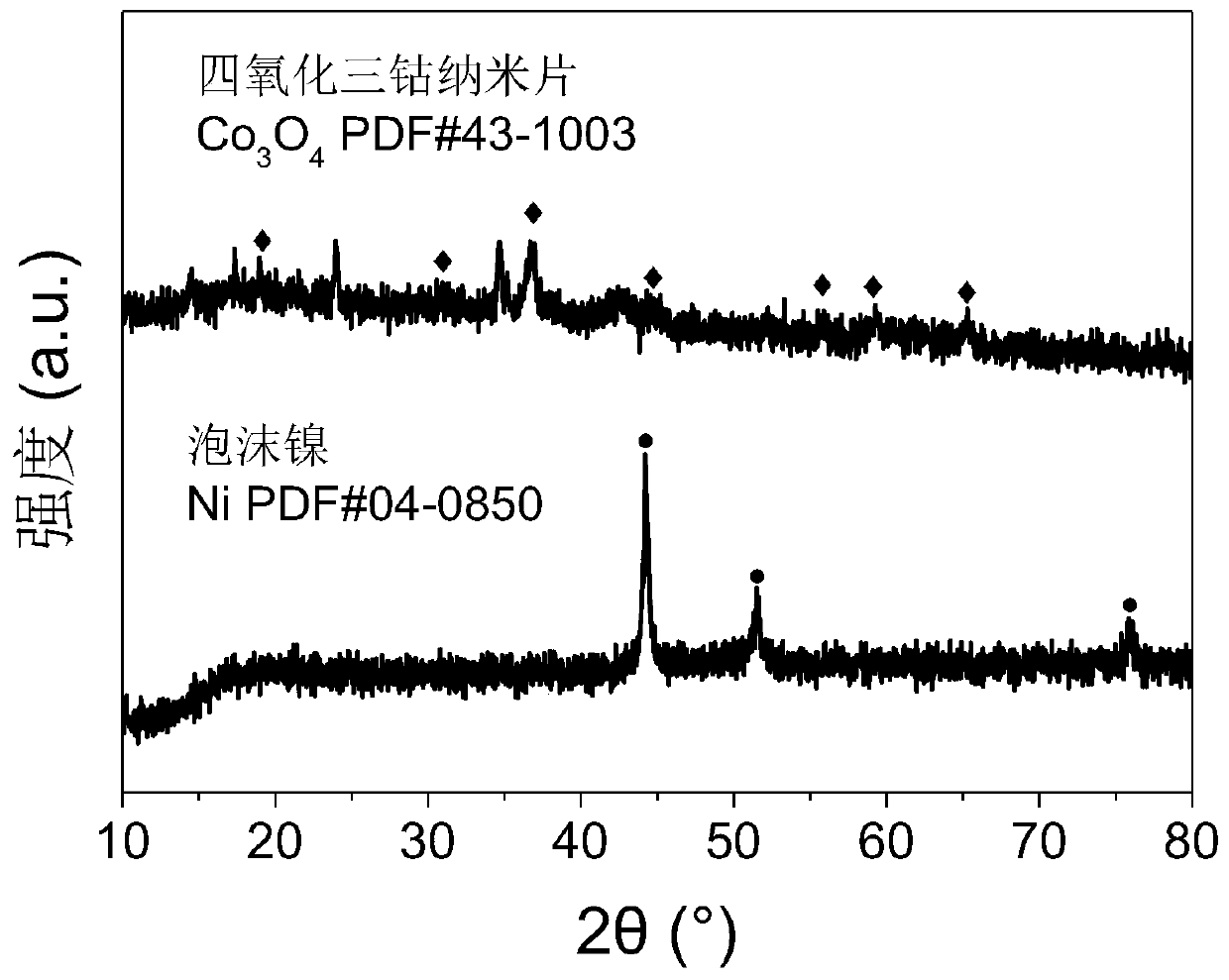

[0082] (1) Add 0.476g CoCl to the beaker 2 ·6H 2 O, 50mL deionized water, stir well at room temperature. Among them, CoCl 2 The molar ratio with water is 1:1400.

[0083] (2) Transfer the solution prepared in step (1) to a 100mL reaction kettle, add a nickel foam base, make it immersed in the solution, put it in an oven and react at 120°C for 6h, take it out and rinse it twice with absolute ethanol , placed in a beaker, put into an oven and dried at 40° C. for 6 hours to obtain a precursor.

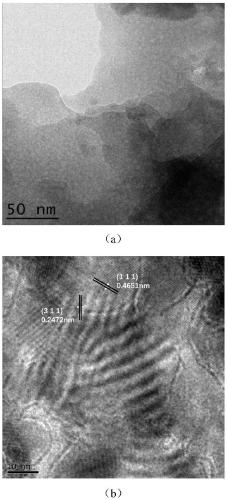

[0084] (3) Put the precursor obtained in step (2) in the quartz boat of the tube furnace, seal it and pass high-purity nitrogen gas as the whole process protective gas, wherein the flow rate of nitrogen gas is 100mL / min; The temperature was raised to 350 °C at a rate of 1 min, and after holding for 0.5 h, it was cooled to room temperature at a rate of 5 °C / min. The obtained product was the monolithic self-assembled cobalt trioxide nanosheet catalyst grown in situ on the nickel foam, w...

Embodiment 2

[0086] (1) Add 0.667g CoCl to the beaker 2 ·6H 2 O, 50mL deionized water, stir well at room temperature. Among them, CoCl 2 The molar ratio with water is 1:1000.

[0087] (2) With embodiment 1.

[0088] (3) Same as Example 1, the obtained sample is designated as sample 2.

[0089] Compared with Example 1, CoCl in the raw material used in this example 2 ·6H 2 The quality of O has changed, and the rest of the preparation conditions have not changed, with the CoCl 2 ·6H 2 With the increase of O quality, the size of the self-assembled cobalt trioxide nanosheets of the final catalyst becomes larger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com