Patents

Literature

44 results about "Macromolecular binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and compositions for needleless delivery of binding partners

InactiveUS20090148401A1Extended half-lifeBetter prophylacticPeptide/protein ingredientsMetabolism disorderBinding domainTranscytosis

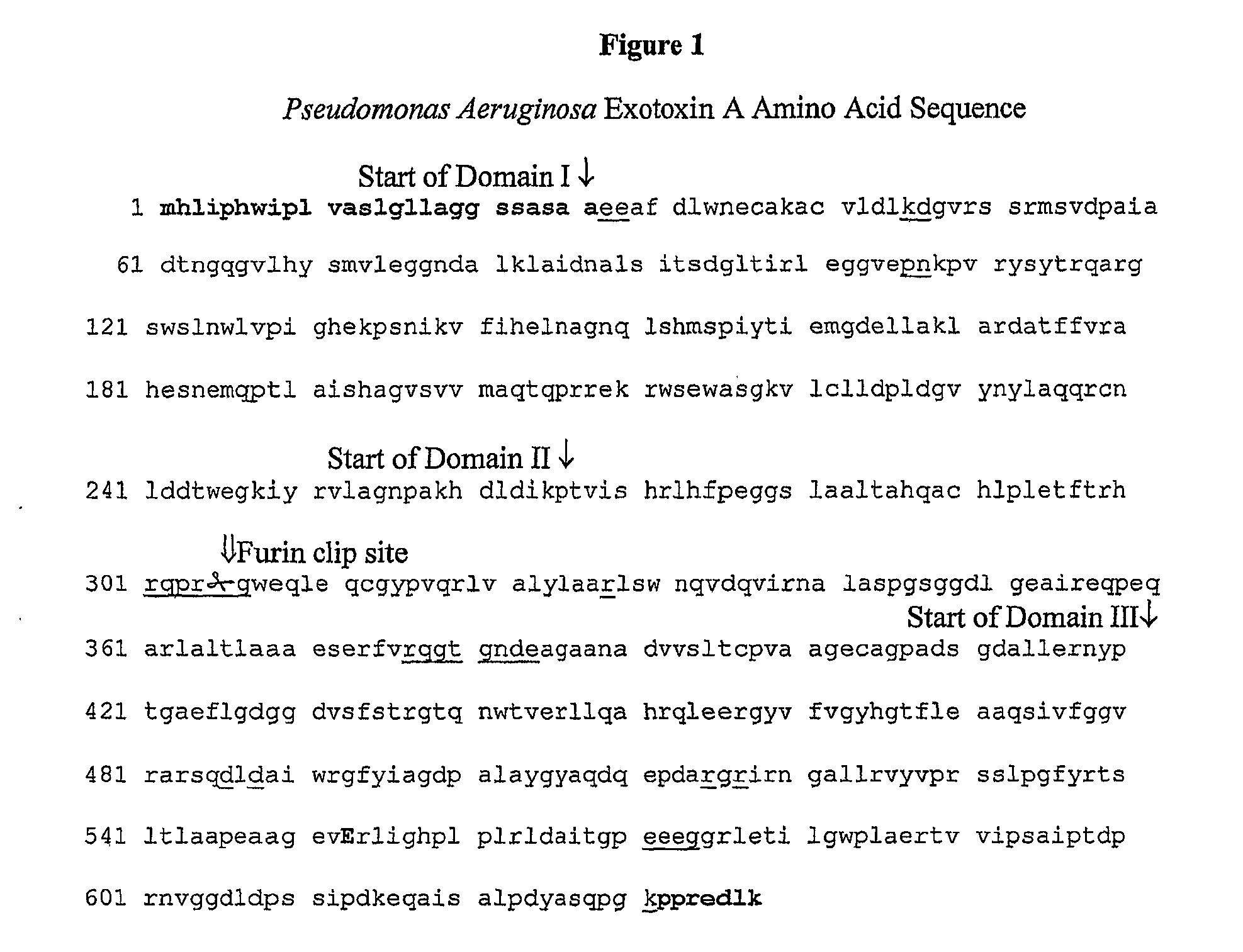

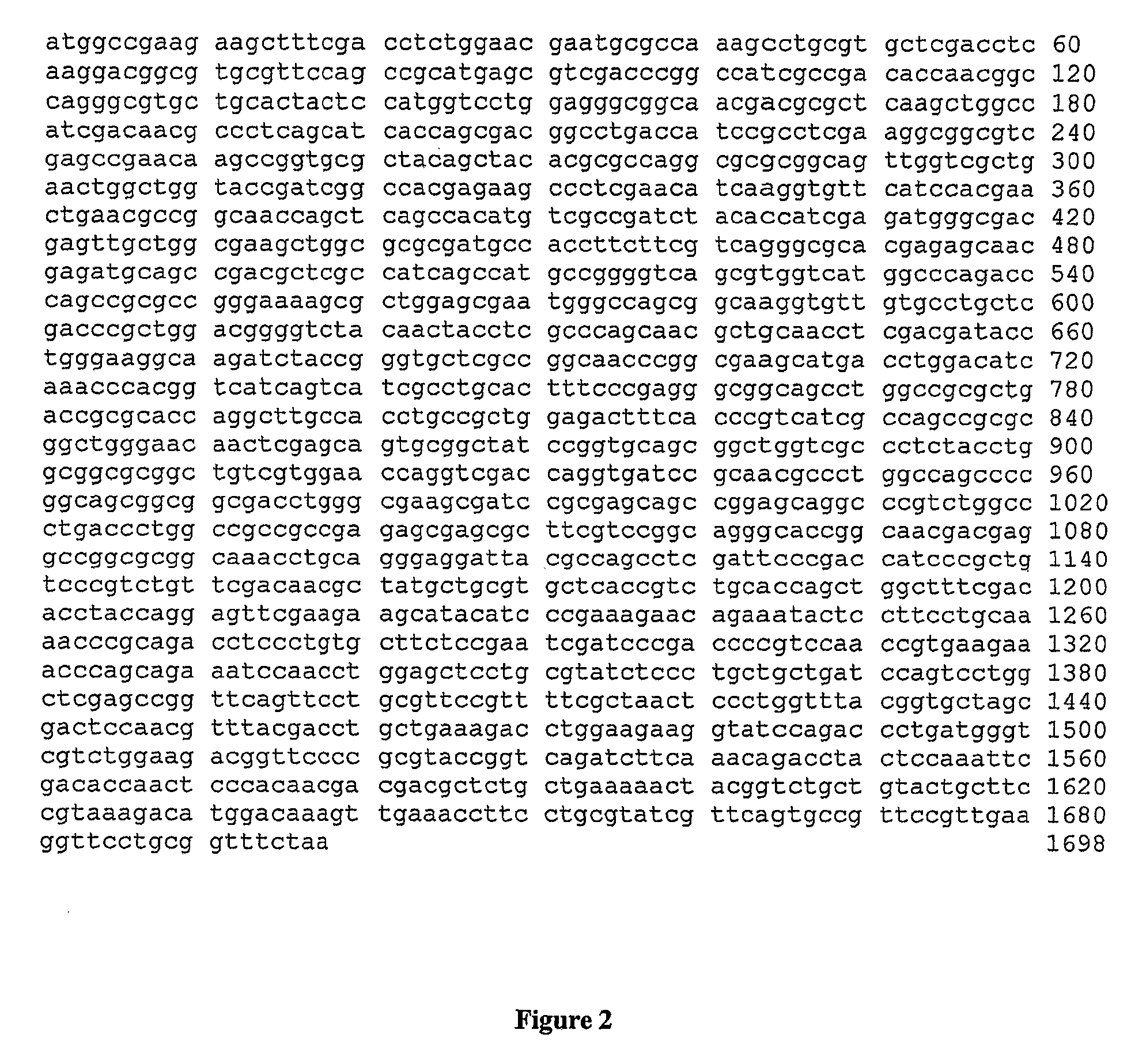

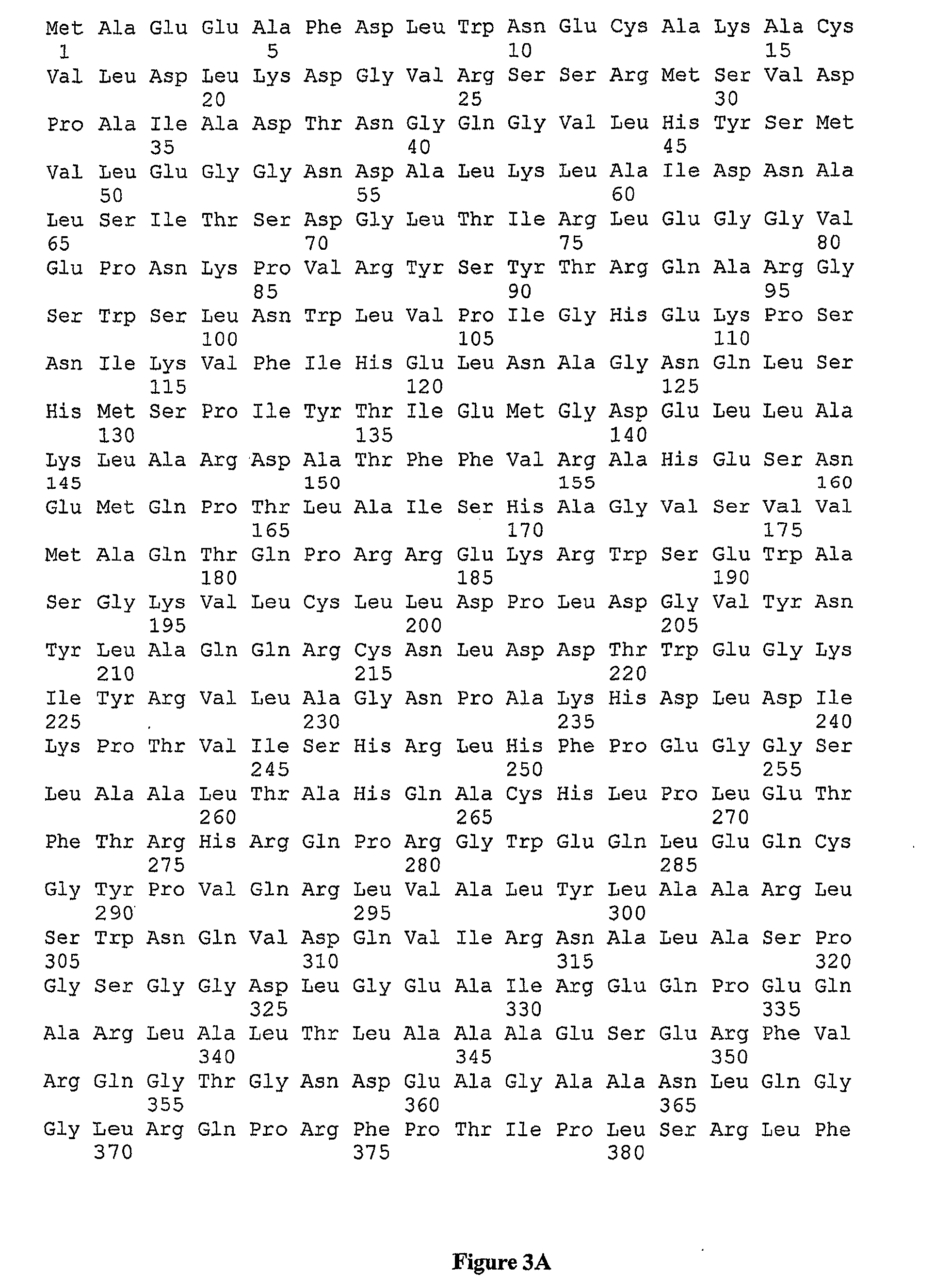

The present invention relates, in part, to methods and compositions for needleless delivery of macromolecules to a subject. In one aspect, the methods and compositions involve administering to the subject a delivery construct comprising a carrier construct non-covalently bound to a binding partner, wherein the carrier construct comprises a receptor-binding domain, a transcytosis domain, and a macromolecule to which the binding partner non-covalently binds, wherein the binding partner binds to the macromolecule with a Ka that is at least about 104 M−1.

Owner:TRINITY ASSIGNMENT FOR THE BENEFIT OF CREDITORS

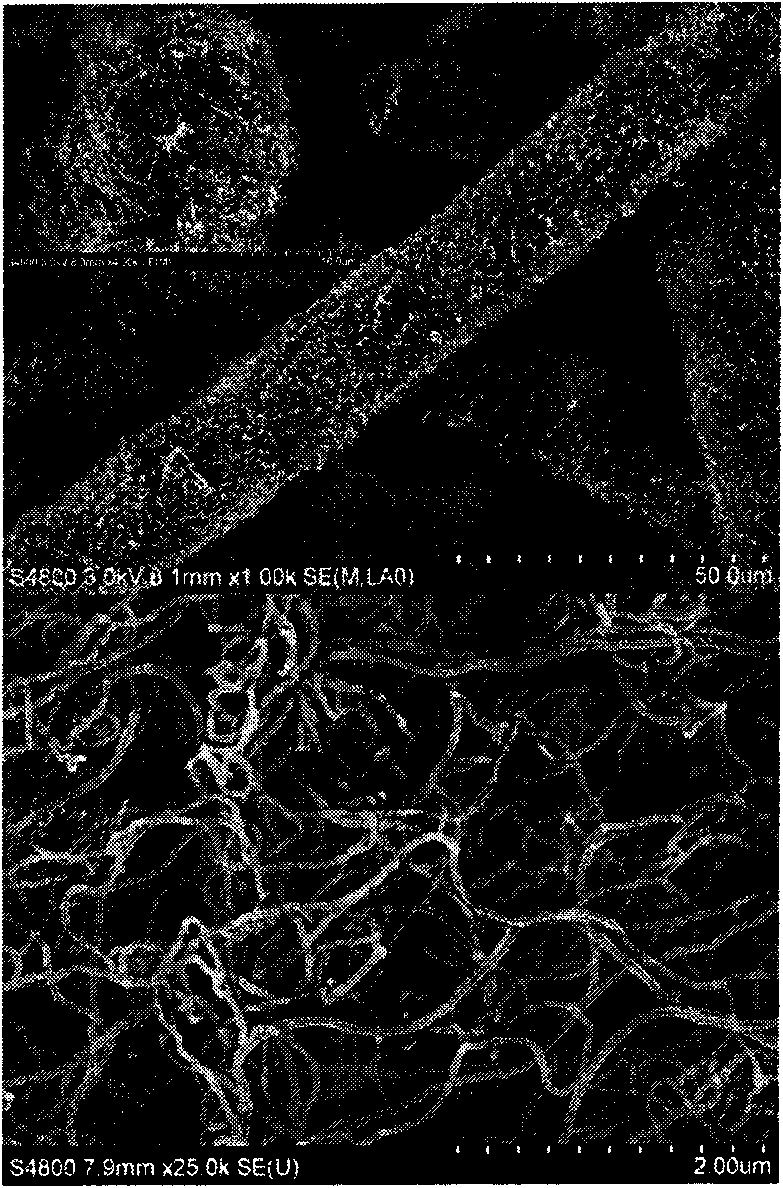

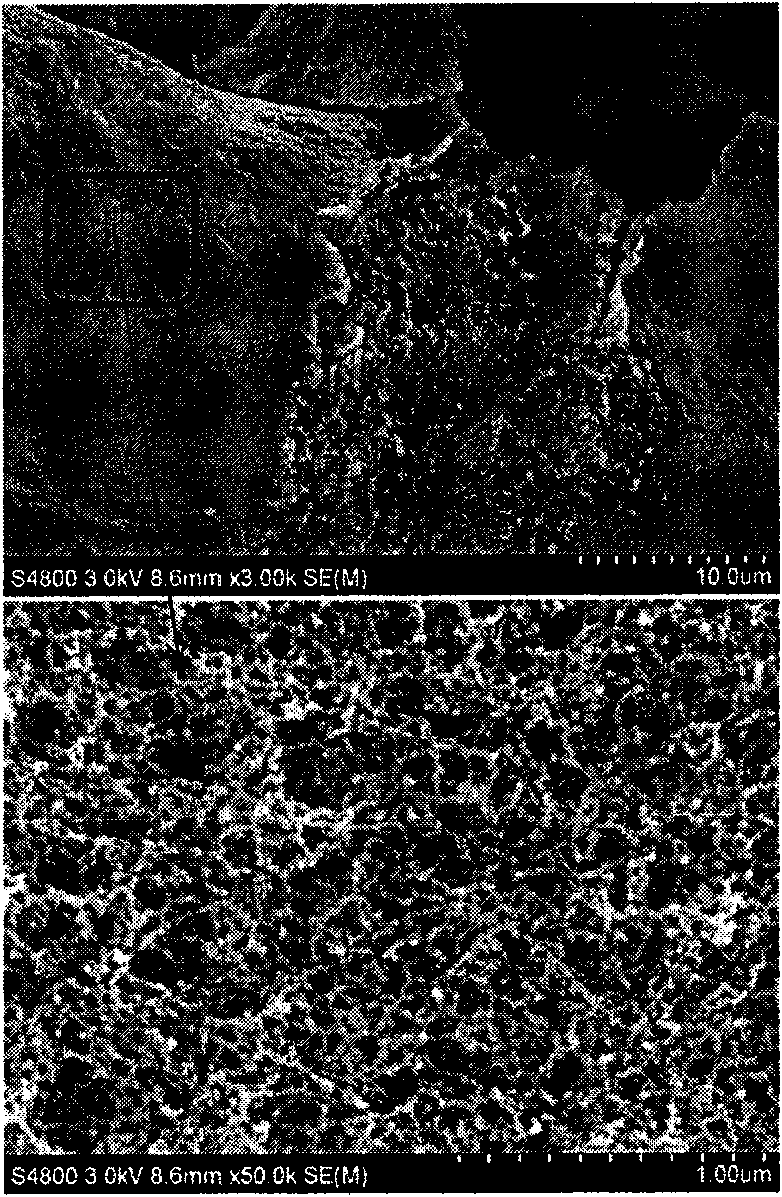

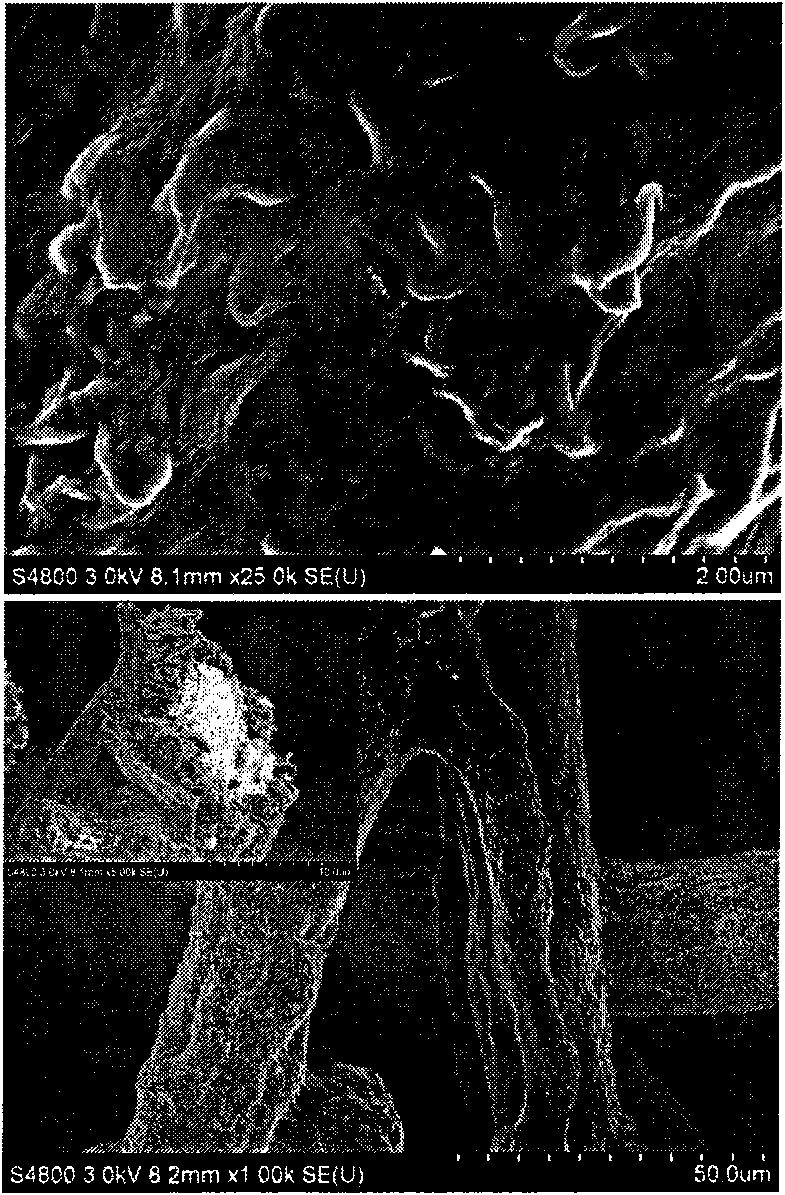

Metal fiber-nanometer carbon fiber-carbon aerogel composite material and preparation method and use thereof

InactiveCN101661839ASelf-supportingGood for electrolyte storageElectrode manufacturing processesHybrid capacitor electrodesMetal fiberInternal resistance

The invention discloses a metal fiber-nanometer carbon fiber-carbon aerogel composite material and a preparation method and a use thereof, wherein, the material contains metal fiber, nanometer carbonfiber and carbon aerogel; a binding point of the metal fiber is sintered on a tri-dimensional net structure, the nanometer carbon fiber grows on the metal fiber, and the carbon aerogel is coated on the nanometer carbon fiber. The preparation method comprises the following steps: sintering the metal fiber net structure in a large area on a selected thin layer; allowing the nanometer carbon fiber togrow by catalyzing a selected chemical vapor phase deposition method of a carbon-containing compound under a specified condition; then coating a selected organic polymer on the nanometer carbon fiber, and carbonizing the polymer at a certain temperature to obtain the metal fiber-nanometer carbon fiber-carbon aerogel composite material. The material can be taken as an electrode material of a novelchemical power supply; and the material has a self-supporting integral structure without an organic polymer macromolecular binding agent, has a tri-dimensional layered hole structure which is beneficial to ion transmission and storage, and has high electrical conductivity, small internal resistance and good chemical energy storage performance.

Owner:EAST CHINA NORMAL UNIV

Methods and compositions for needleless delivery of binding partners

InactiveUS20070148131A1Extended half-lifeImprove welfarePeptide/protein ingredientsCalcitoninsNeedle freeReceptor

The present invention relates, in part, to methods and compositions for needleless delivery of macromolecules to a subject. In one aspect, the methods and compositions involve administering to the subject a delivery construct comprising a carrier construct non-covalently bound to a binding partner, wherein the carrier construct comprises a receptor-binding domain, a transcytosis domain, and a macromolecule to which the binding partner non-covalently binds, wherein the binding partner binds to the macromolecule with a Ka that is at least about 104 M−1.

Owner:TRINITY ASSIGNMENT FOR THE BENEFIT OF CREDITORS

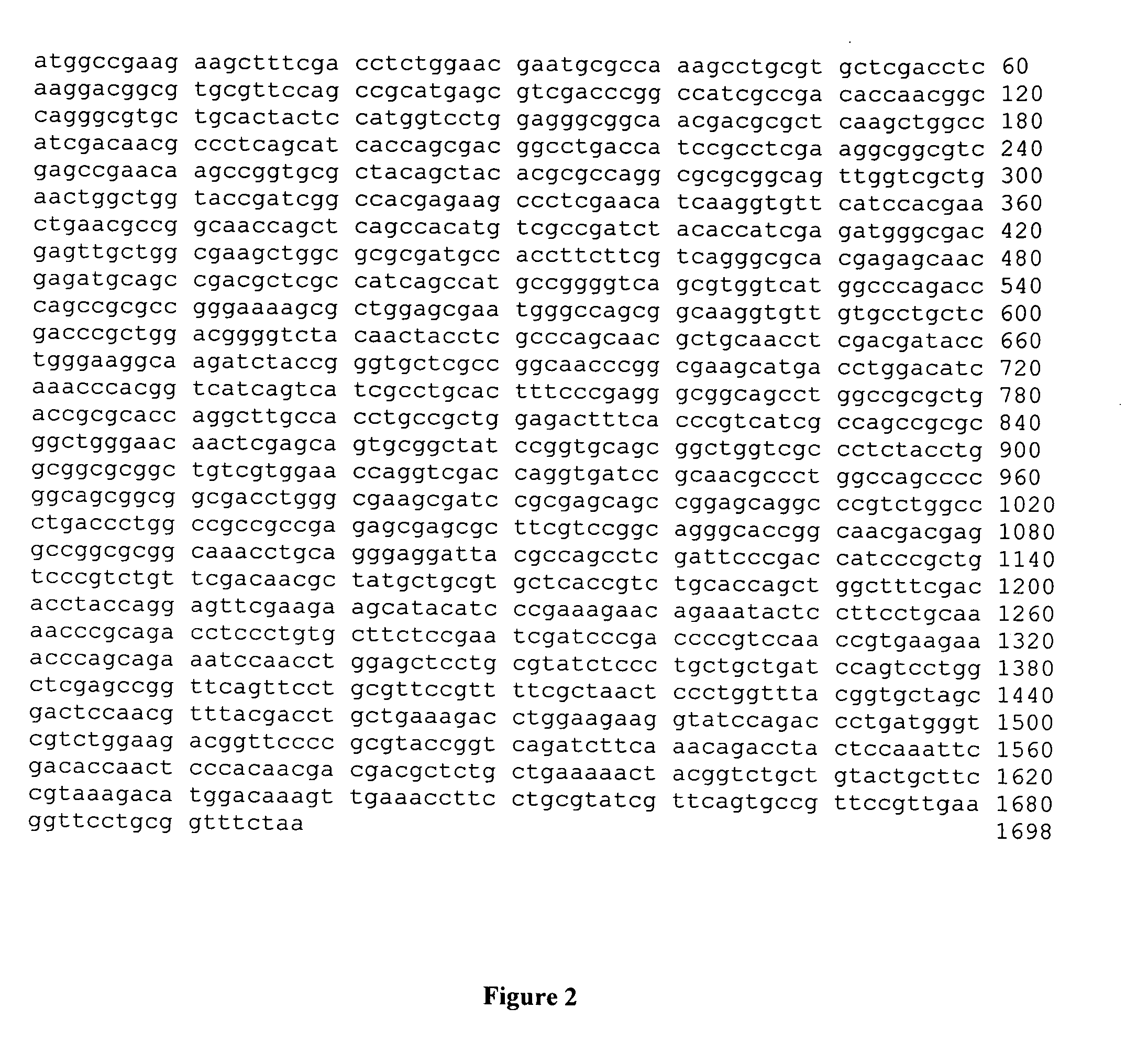

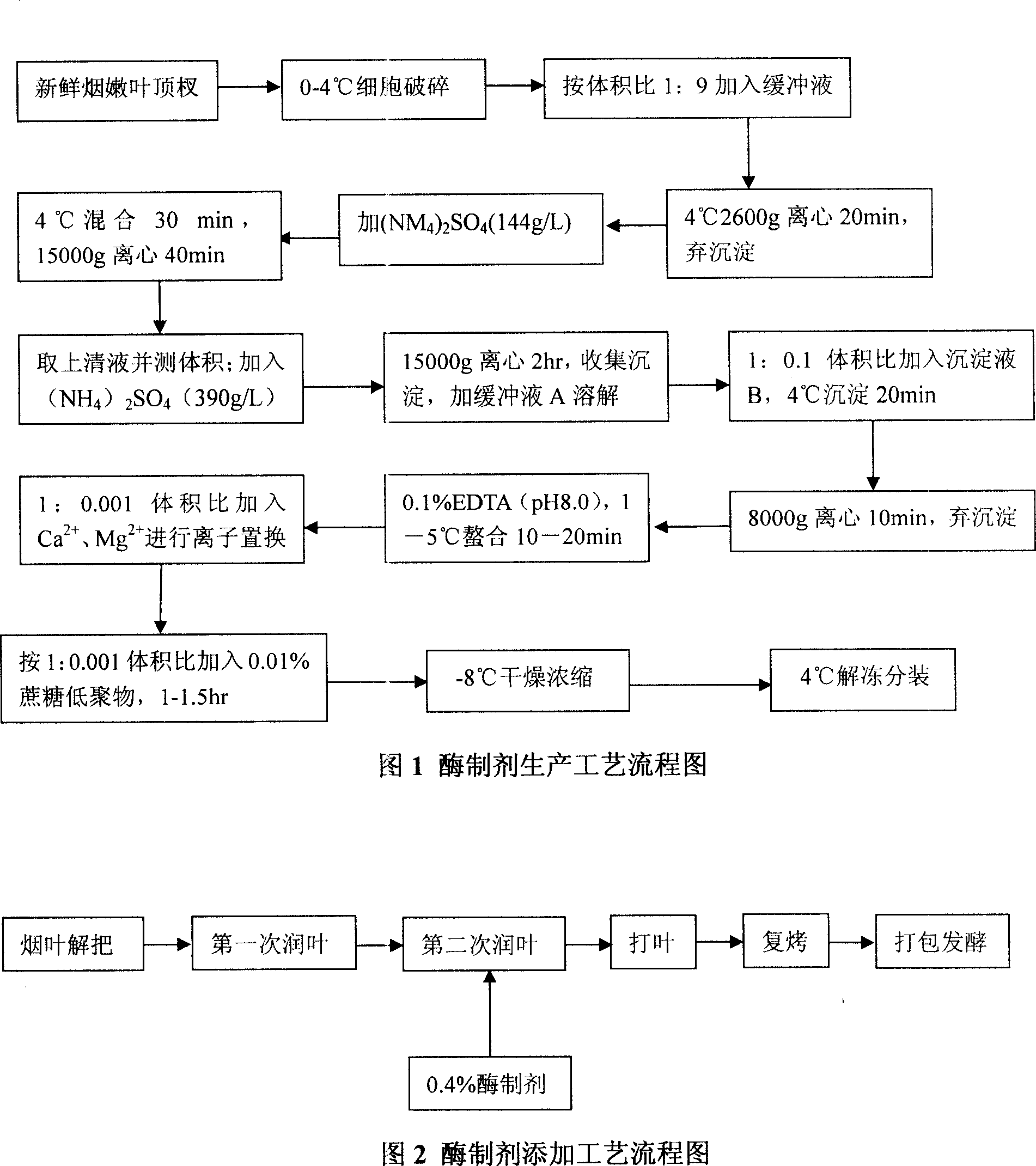

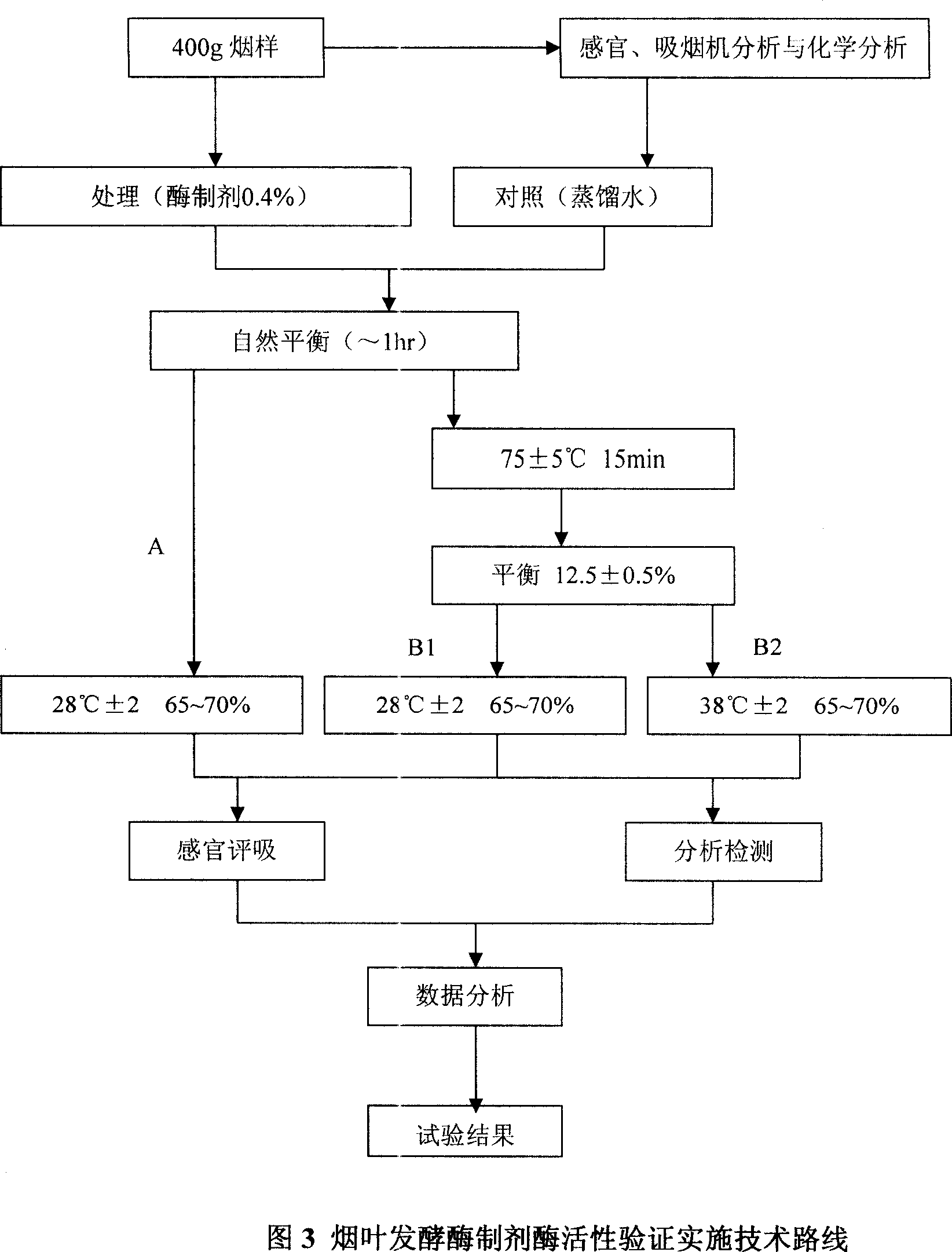

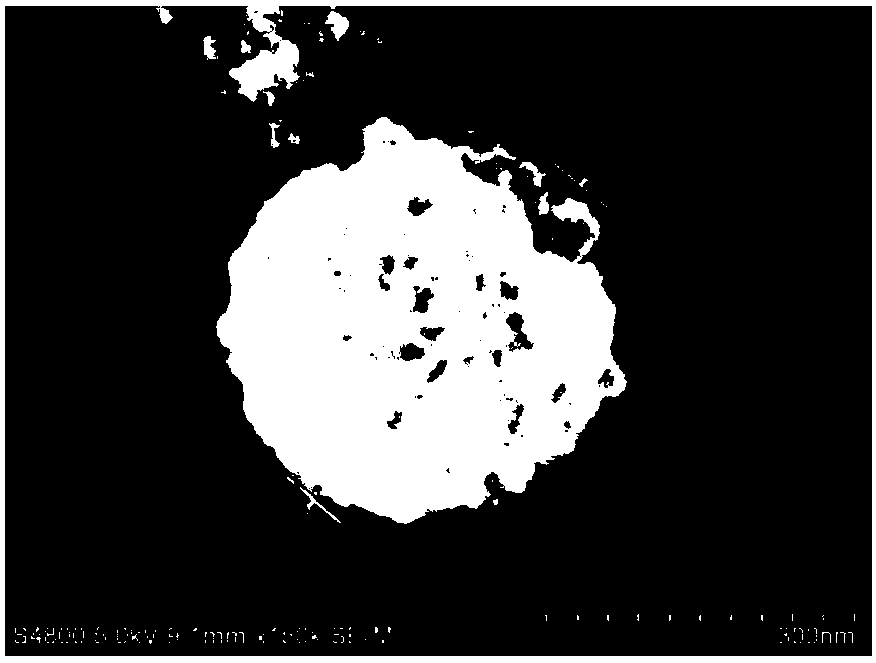

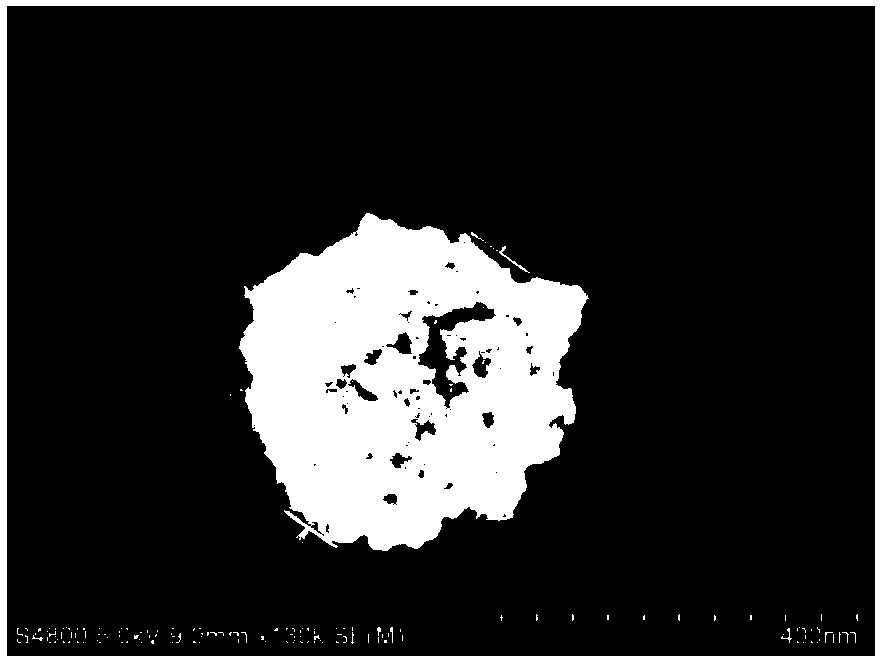

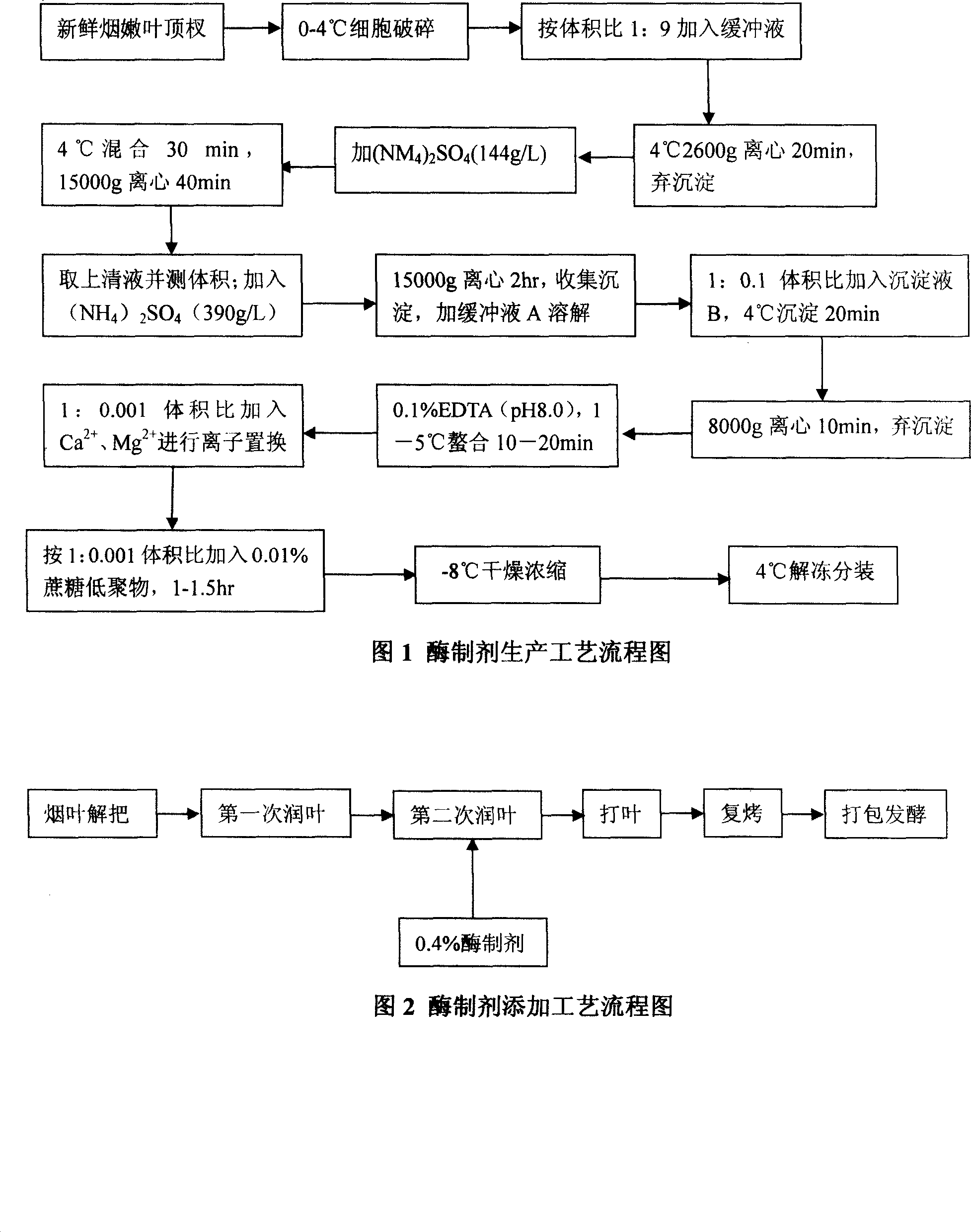

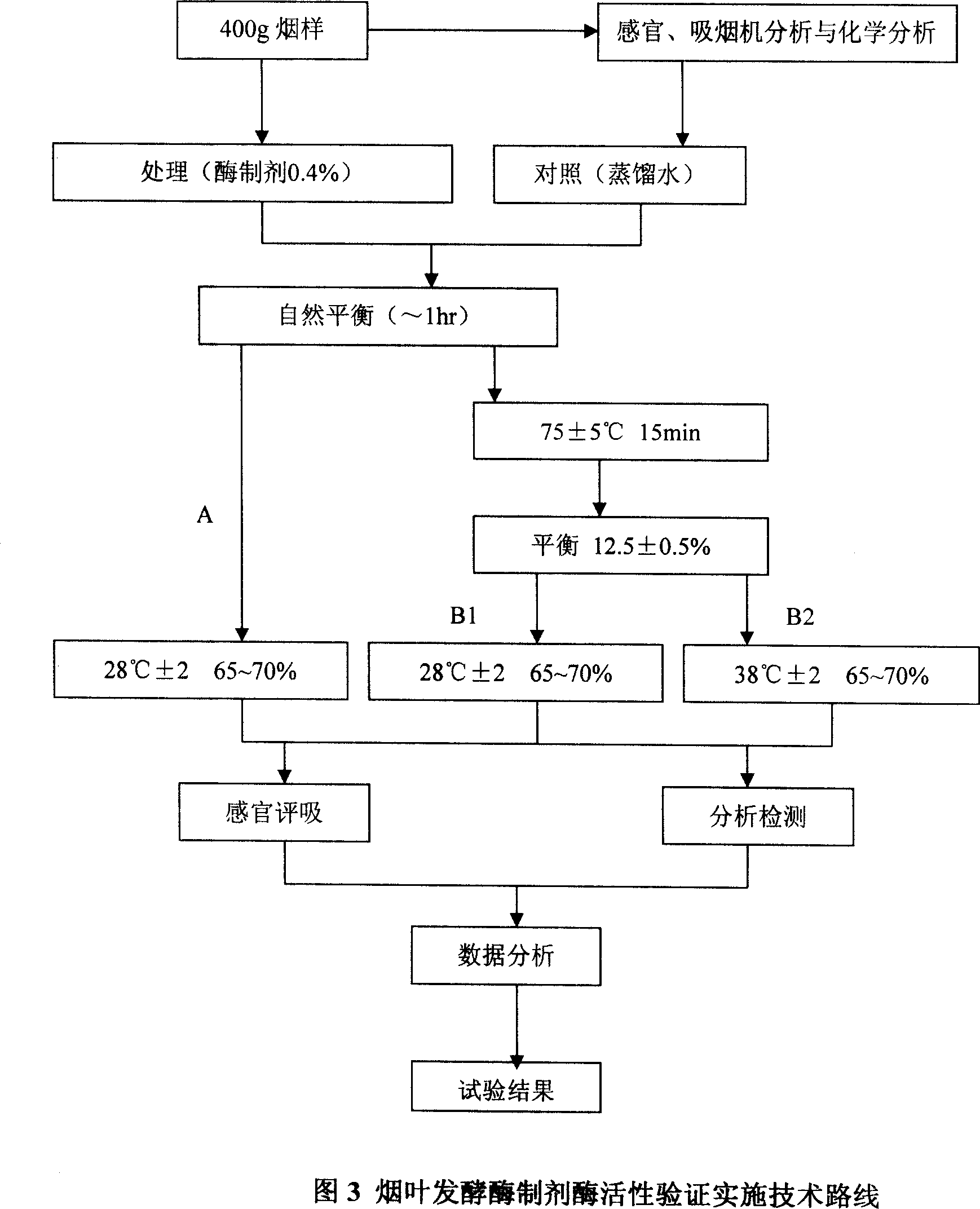

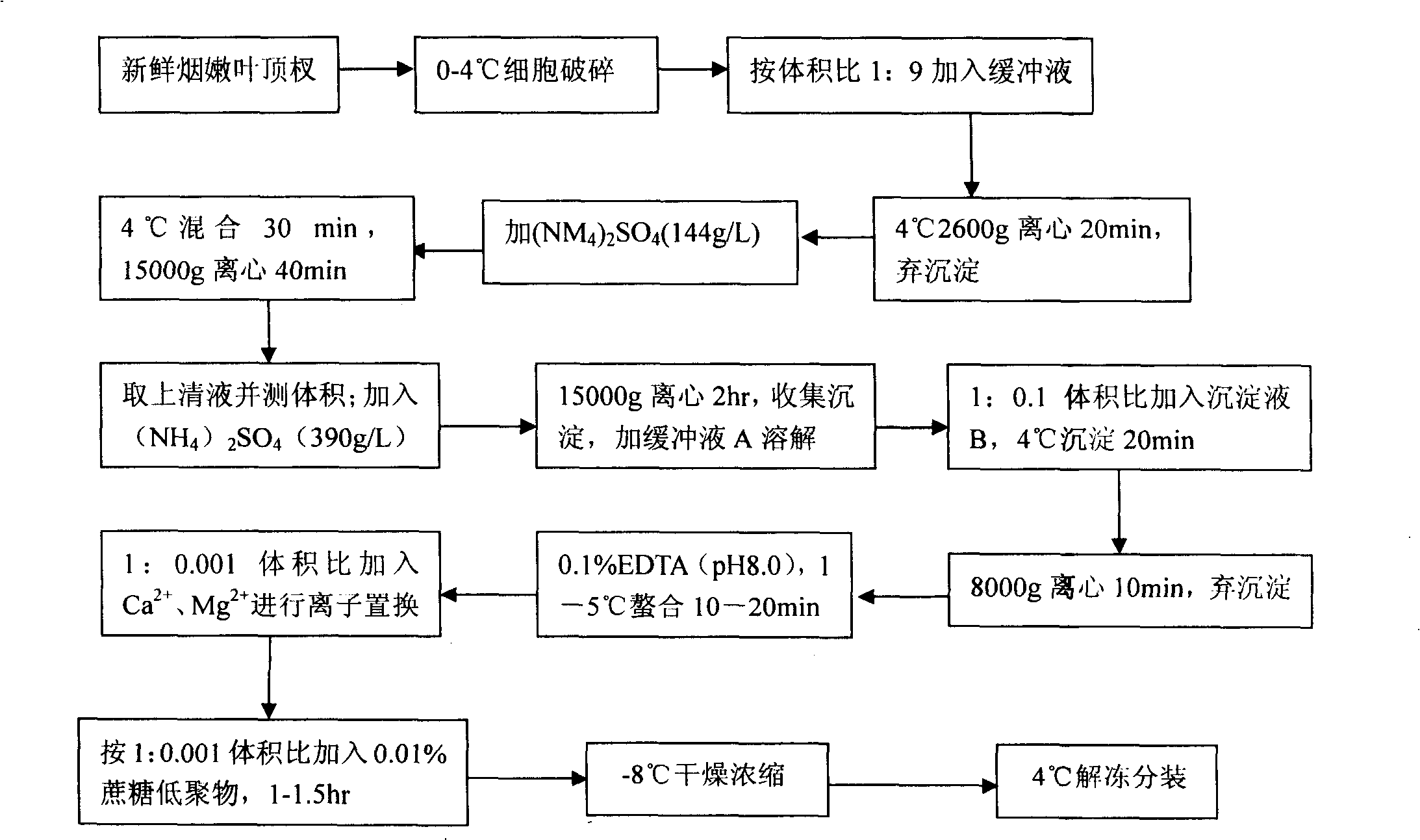

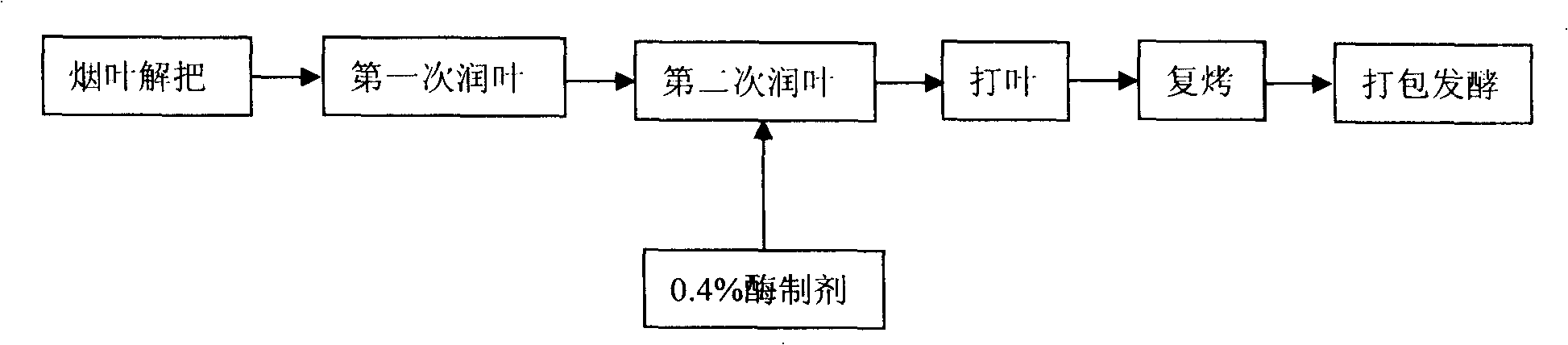

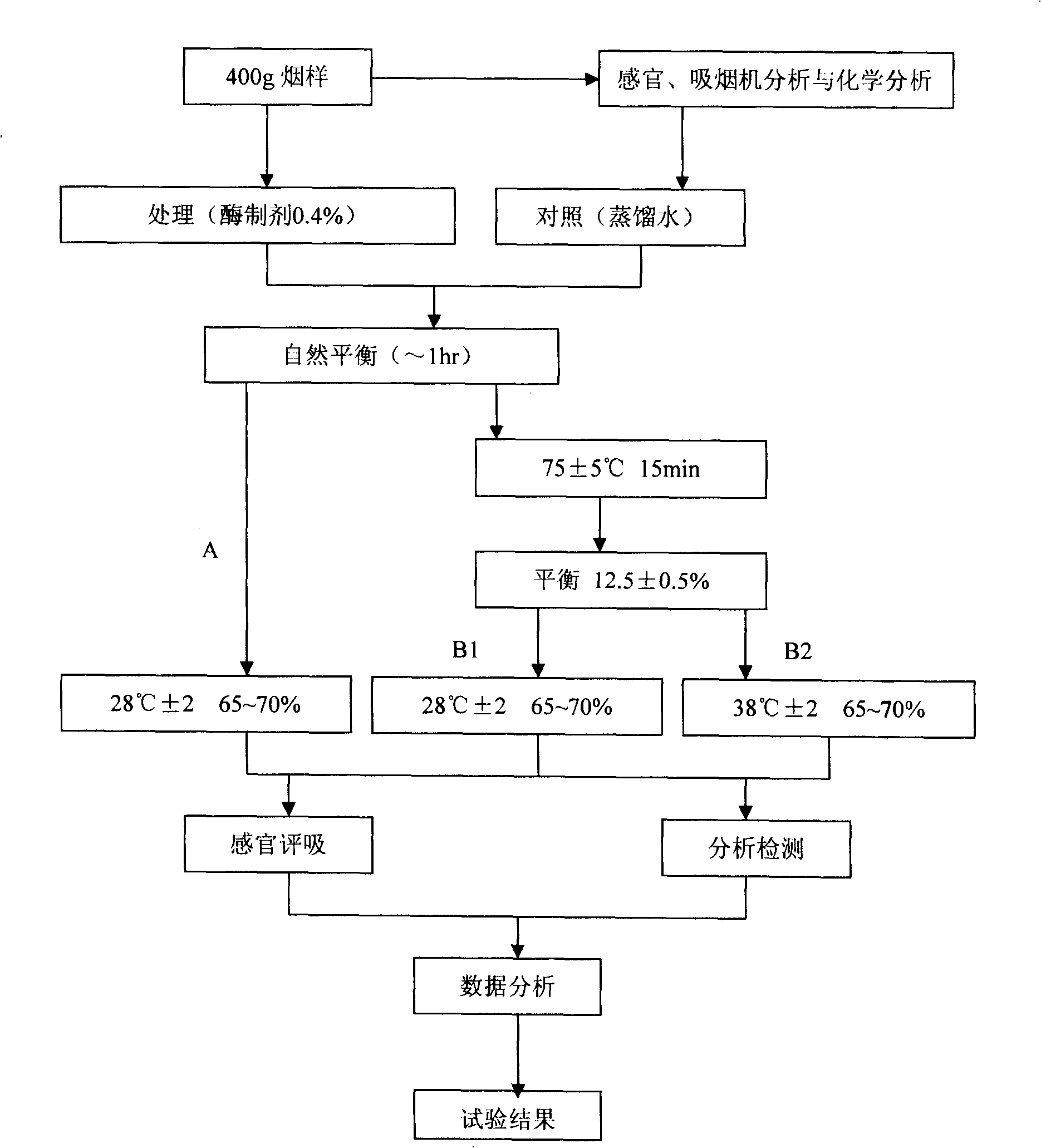

Method for producing tobacco leaf fermenting enzyme preparation

InactiveCN101144073AGood application effectIt has the characteristics of high temperature resistance of rebaking lineTobacco treatmentEnzymesBiotechnologySaccharum

The present invention relates to a novel tobacco leaf fermenting enzyme preparation production method which aims to solve the technical problems that how the quality of the tobacco leaf fermenting product is improved and how the reactivity protection of the tobacco leaf fermenting enzyme preparation is realized in the natural fermenting field of the tobacco leaf. The enzyme preparation consists of glucoseoxidase, chlorophyl oxidase, carotenoid oxidase, protease, and nicotine-degradation enzyme. Through the cell disruption of fresh leaves, (NH 4) 2 SO 4 is utilized to operate the second fractional precipitation to obtain crude enzyme fluid, an enzyme molecule adopts Ca 2 + and Mg 2 + to operate the metal ion exchange, to accomplish the molecule modification; a macro molecule combination modification is accomplished through adopting 0.01 percent of cane sugar low molecular polymer, thereby prolonging the half life period of an enzyme preparation, and obviously improving the high temperature resistant ability. The experimental result employed by the enzyme preparation indicates that the nicotine is decreased by 9.3 percent, the total nitrogen is decreased by 5.7 percent, the protein is decreased by 7.1 percent; cigarette smoke condensates are decreased by 8.4 percent, the tar content is decreased by 5.1 percent, cigarette smoke nicotine content is decreased by 28.0 percent, and the carbon is decreased monoxide by 1.6 percent. The enzyme preparation is employed when the tobacco is wet for the second time before defolat and redrying.

Owner:谢勇 +2

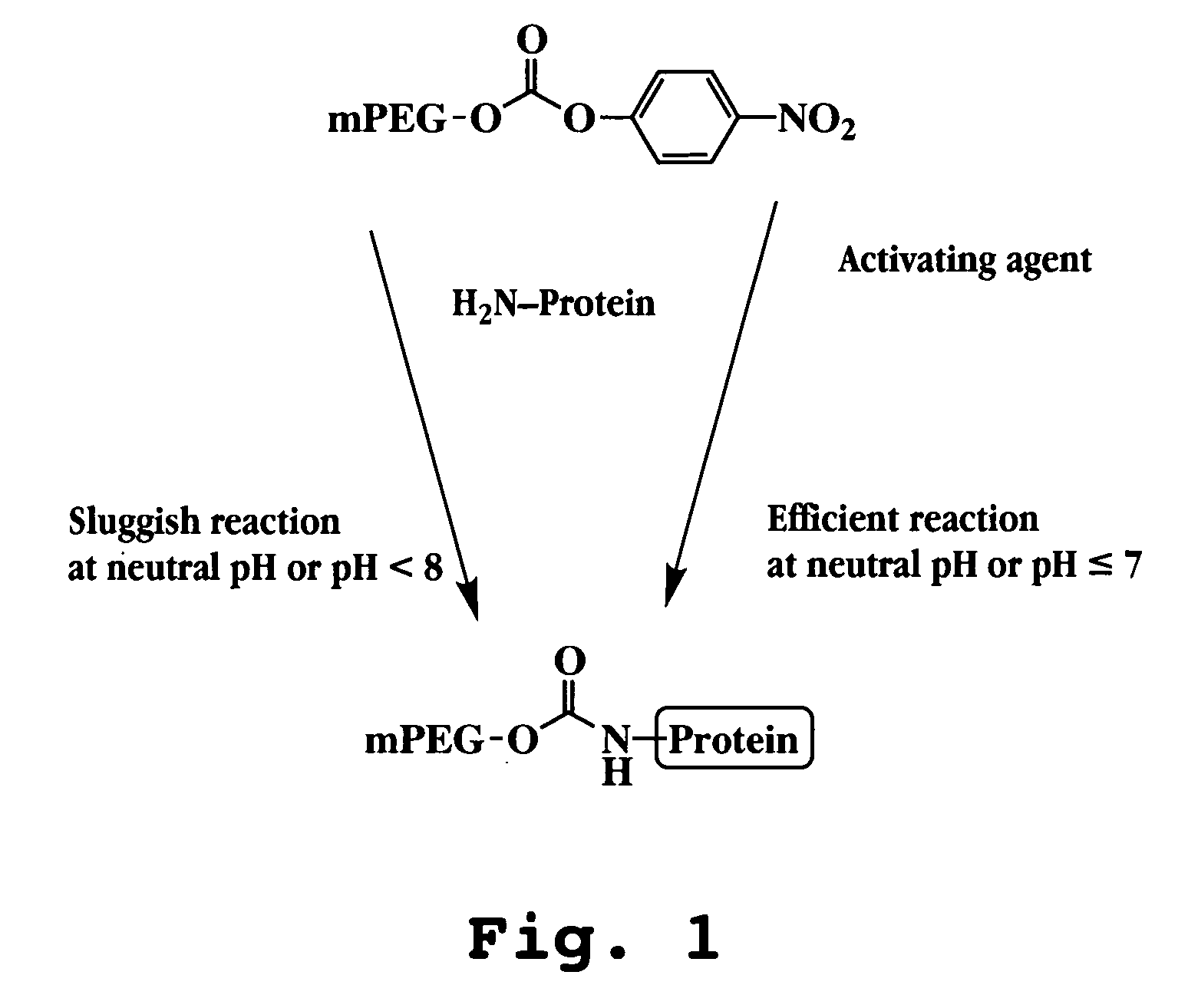

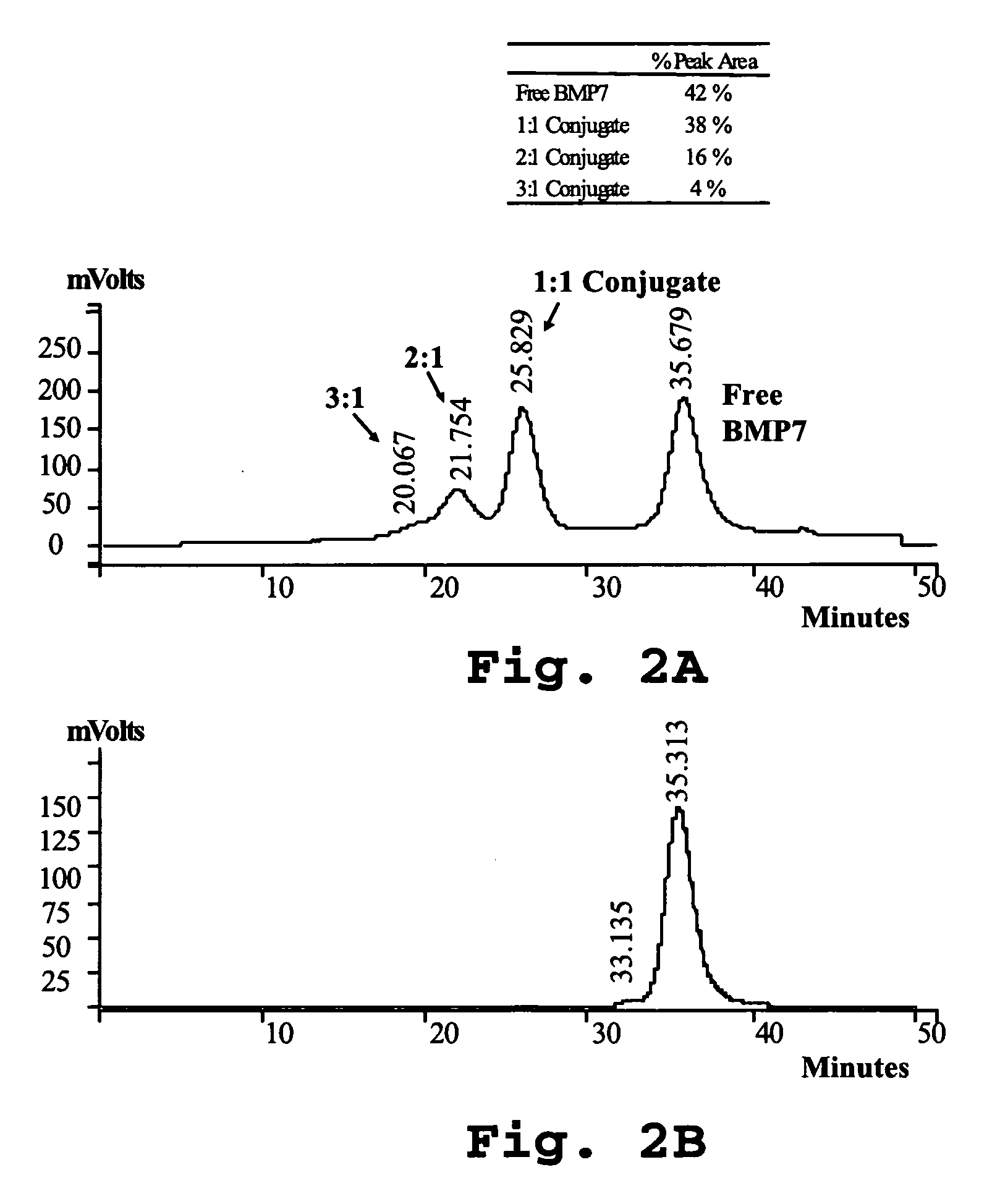

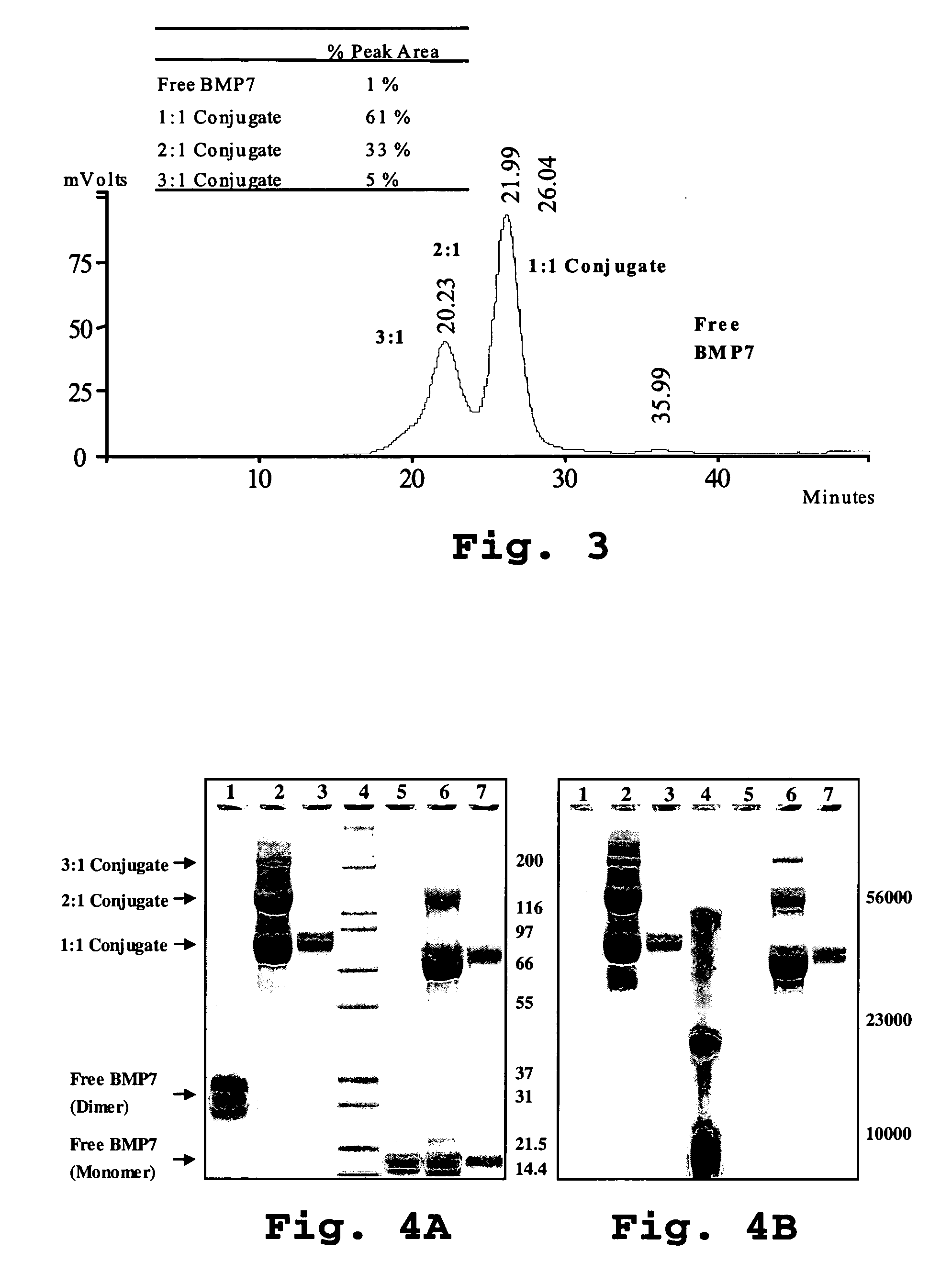

Macromolecular conjugates of bone morphogenetic protein-7

InactiveUS20070015701A1Antibacterial agentsPeptide/protein ingredientsHydrophilic polymersBone morphogenetic protein 6

A modified bone morphogenetic protein (BMP, also referred to as bone morphogenic protein) composition is described. The bone morphogenetic protein, in one embodiment, is BMP-7 which is chemically modified with a hydrophilic polymer, such as poly(ethylene glycol).

Owner:ALZA CORP

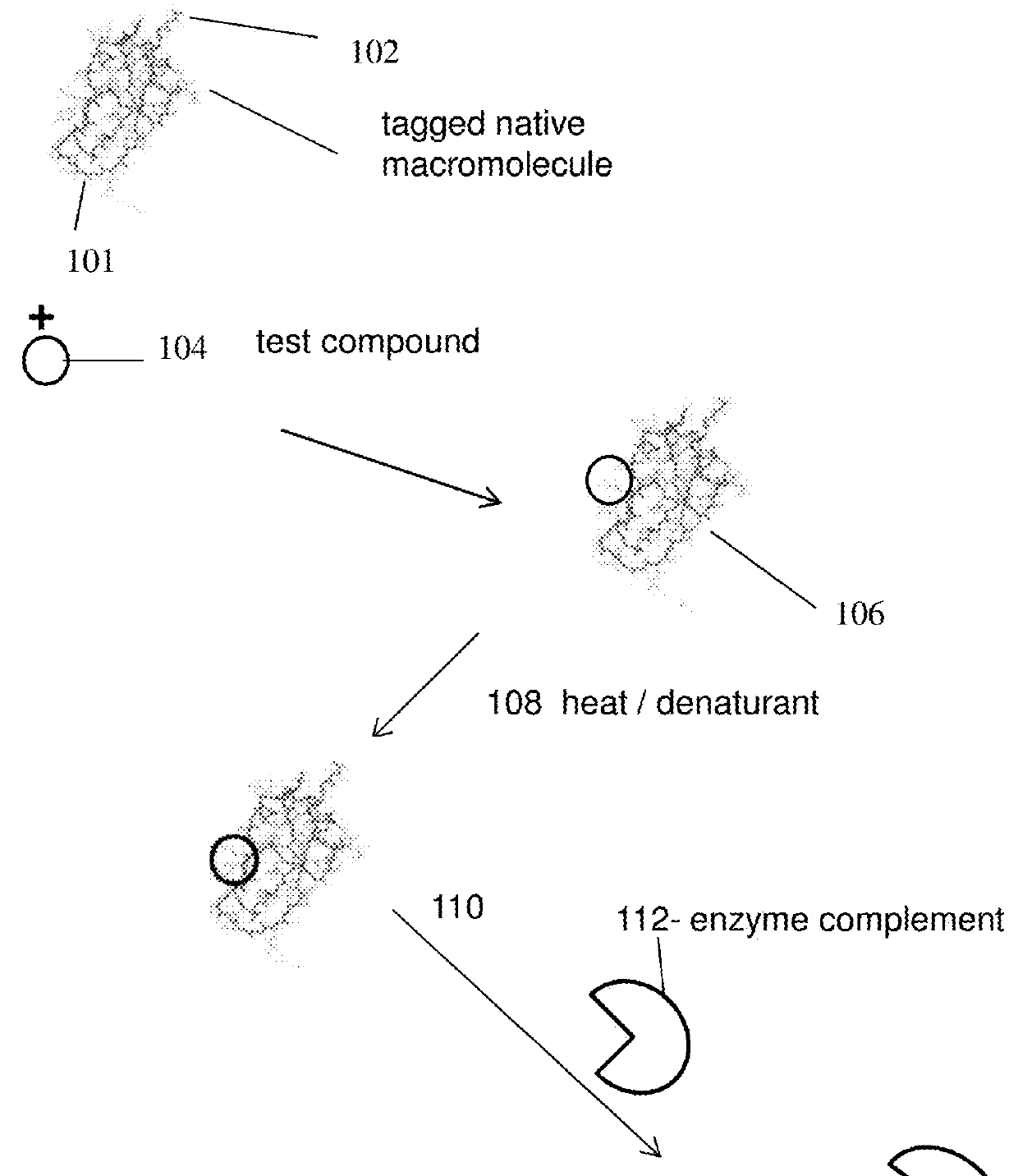

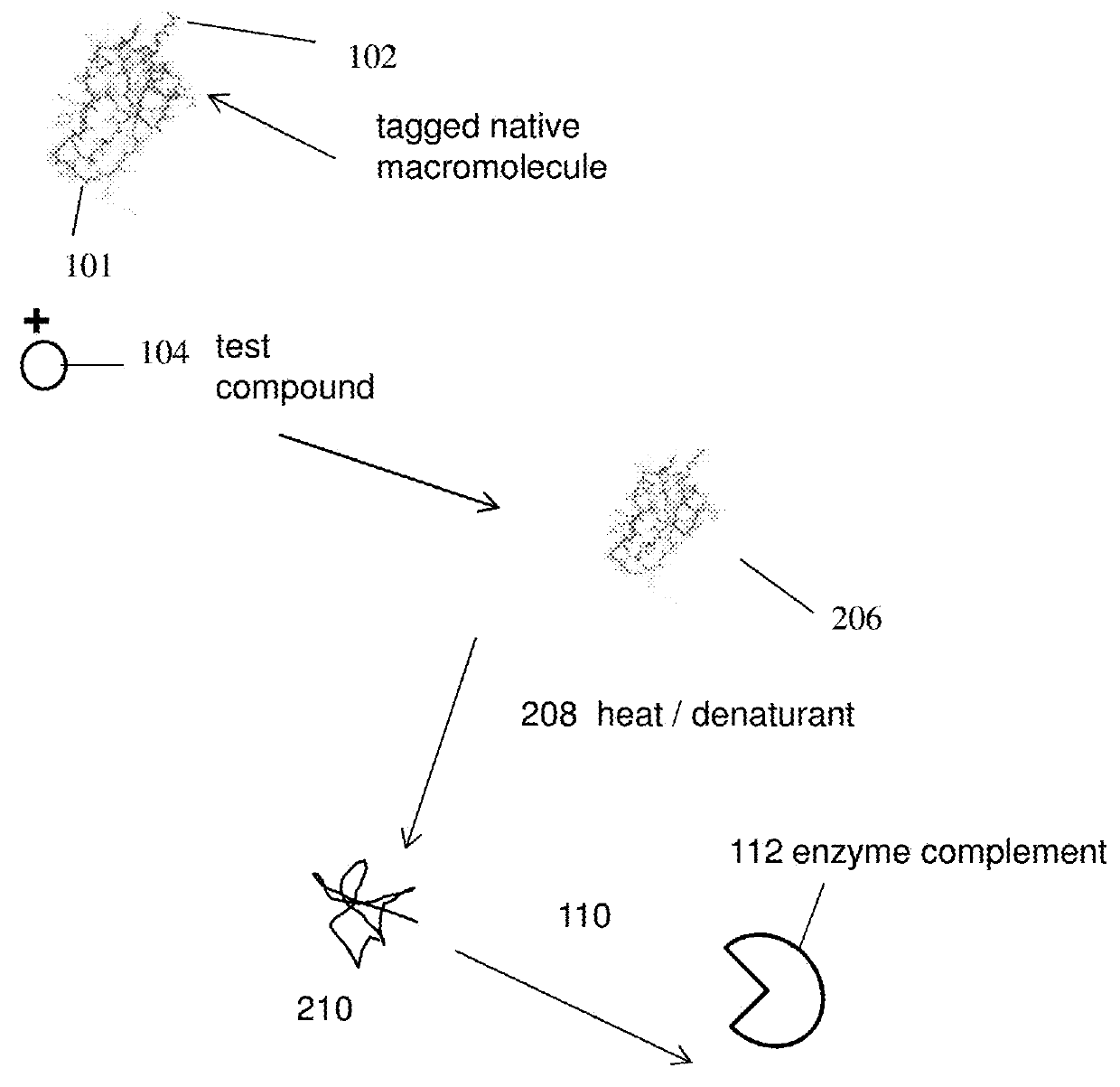

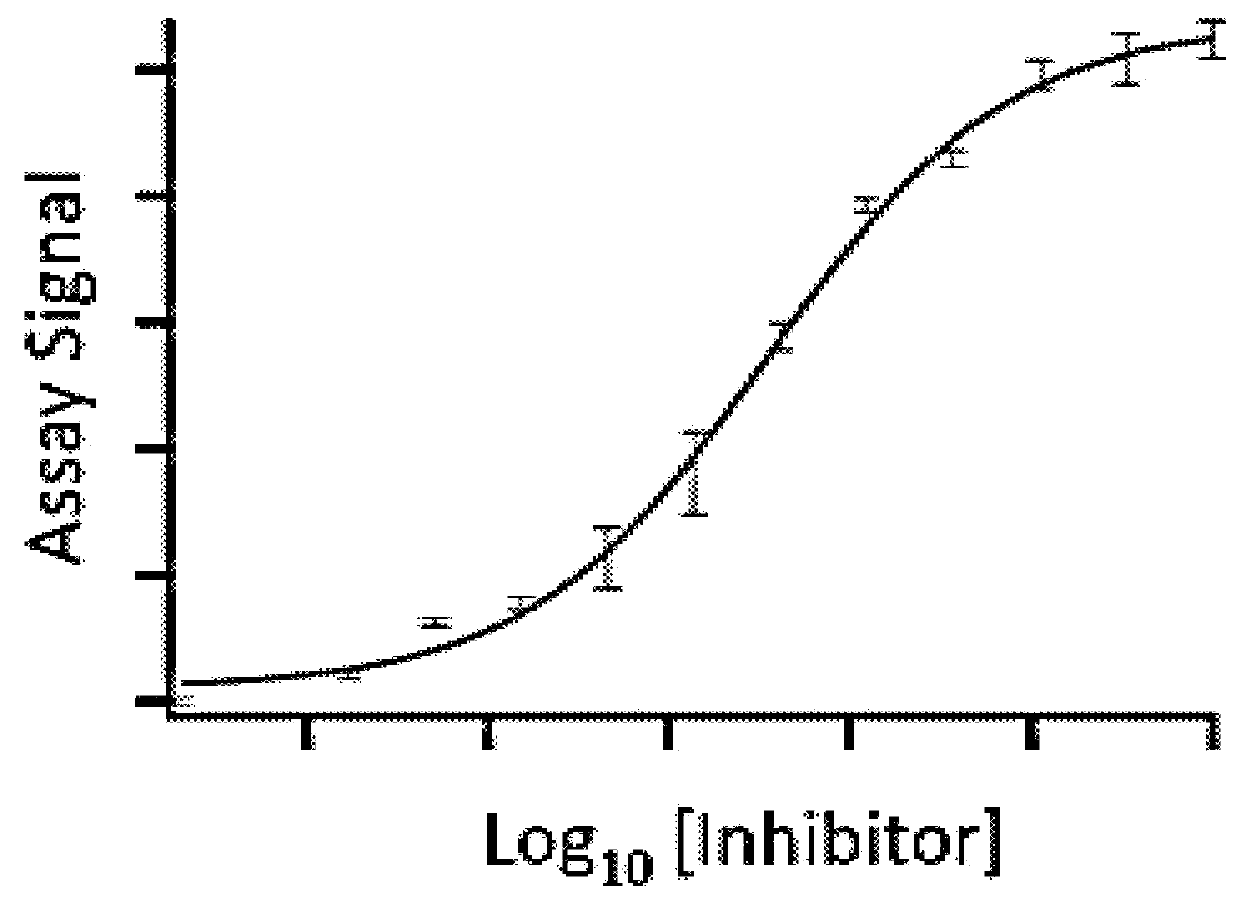

Homogenous thermal shift ligand binding assay

ActiveUS20160054322A1High statistical significanceCompound screeningApoptosis detectionEnzyme fragment complementationBound property

Disclosed are methods for detecting and quantitatively measuring a binding property of a compound to a target macromolecule, wherein the target macromolecule is subject to denaturation and is linked to a labeling peptide, such as a short enzyme fragment. The method uses a fluid mixture comprising (i) a chimeric molecule comprising a target macromolecule linked to the labeling peptide and (ii) a compound being measured for binding to the target macromolecule, wherein said target macromolecule is subject to denaturation. After allowing for binding of the compound (e.g. a small molecule inhibitor of the target macromolecule), one detects a signal from the labeling peptide, such as by enzyme fragment complementation. This signal indicates a differential between denatured and non-denatured target macromolecules and thereby indicates a differential between target macromolecules not bound to the compound and target macromolecules bound to the compound, respectively.

Owner:DISCOVERYX CORP

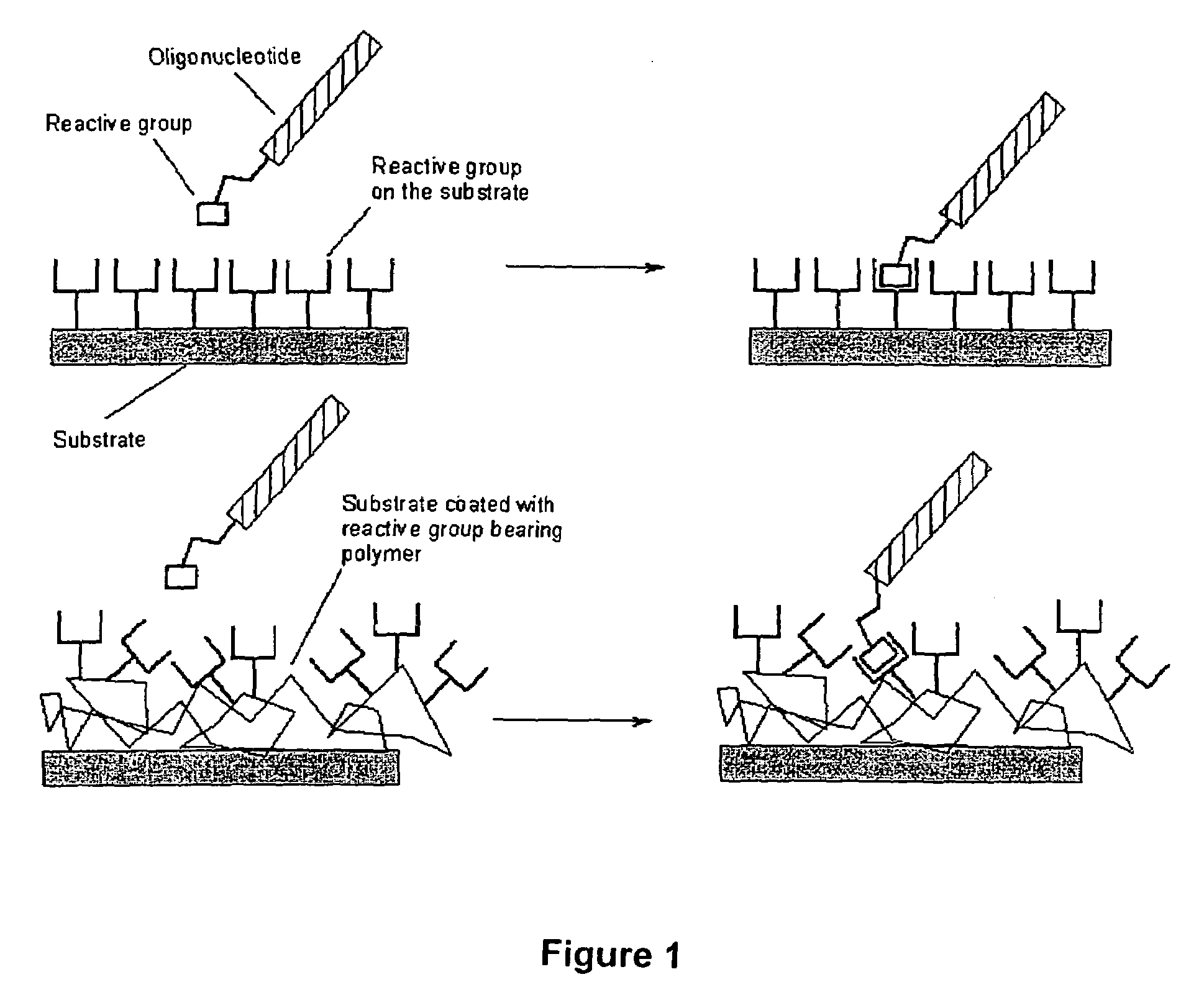

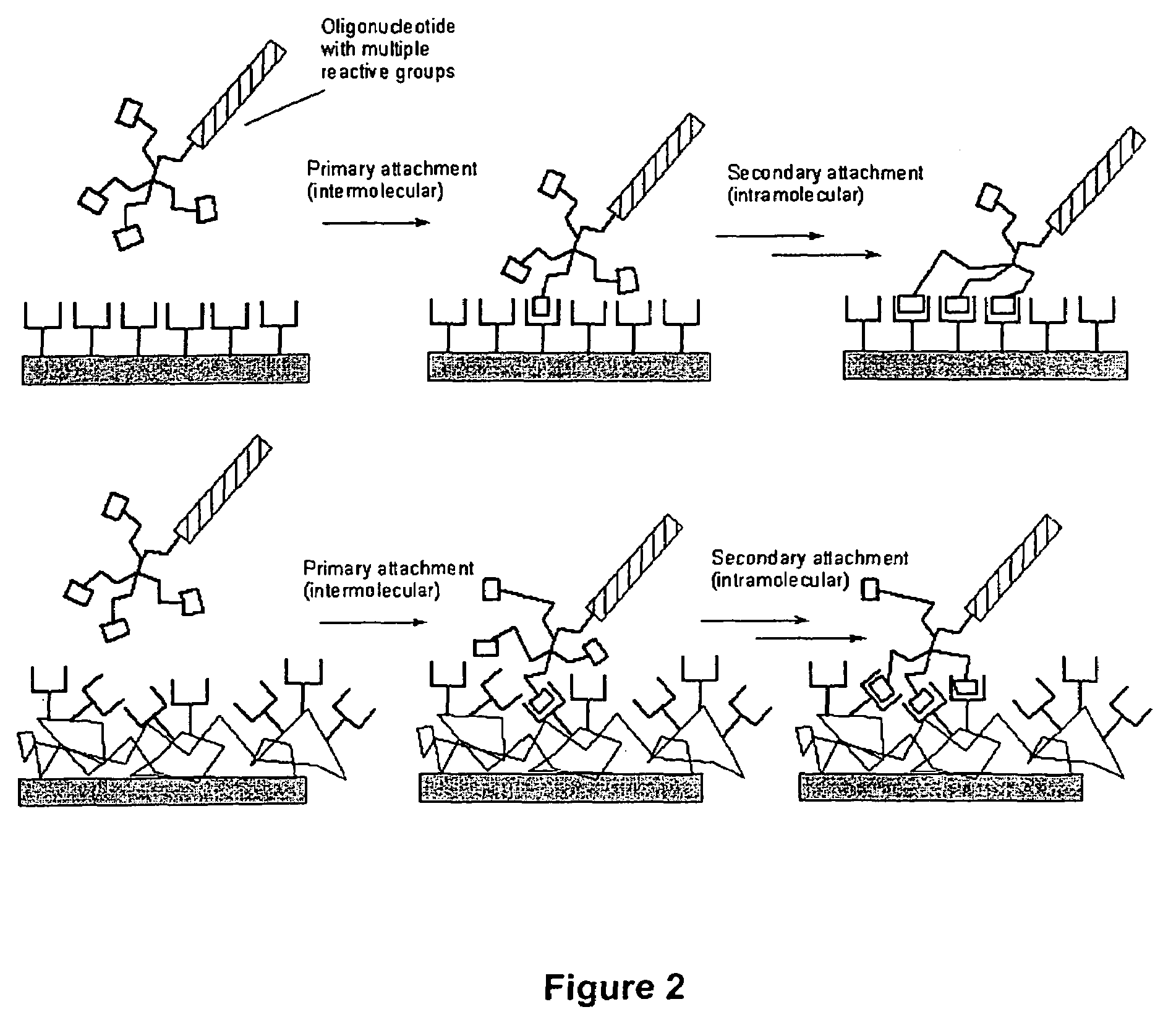

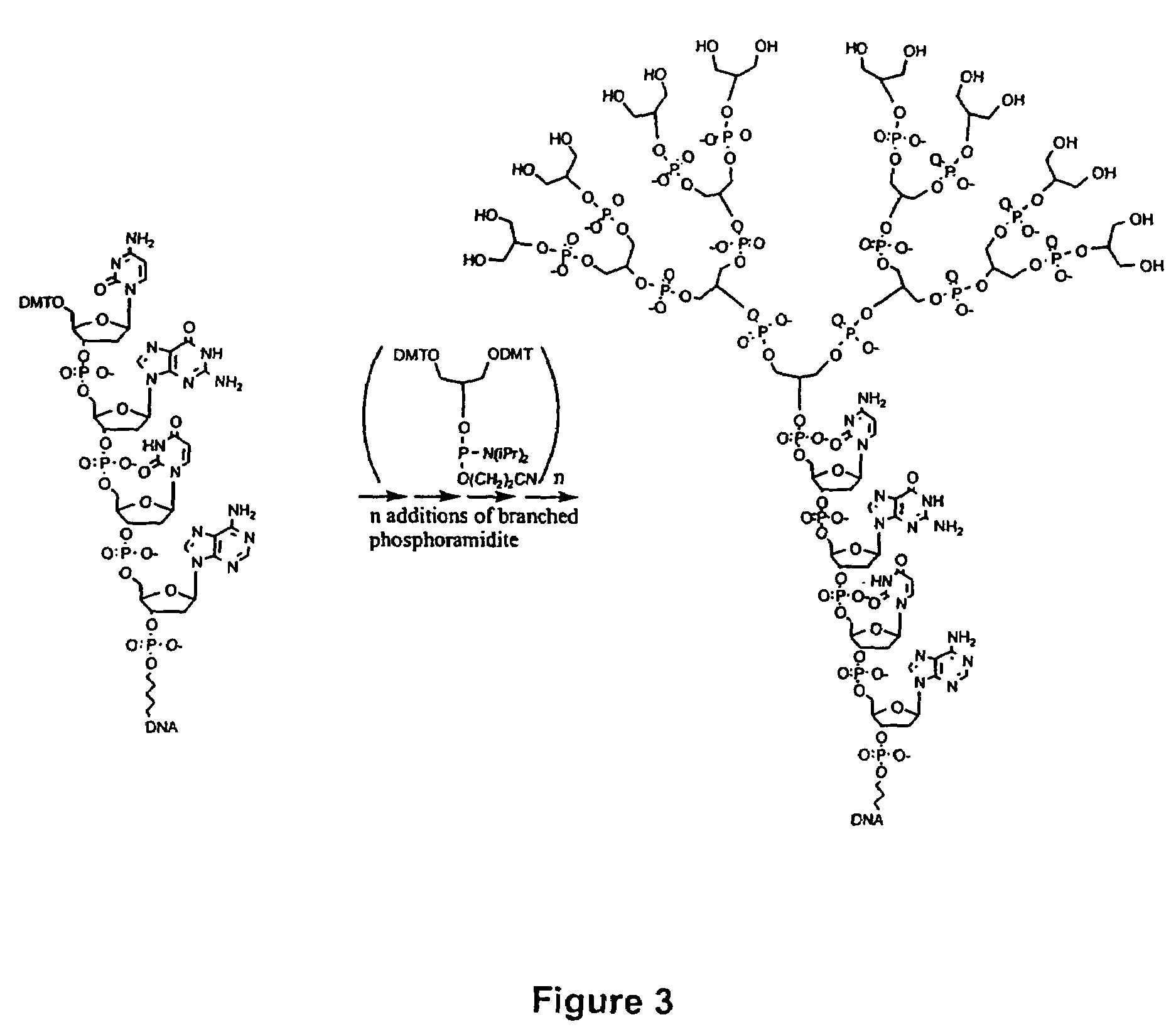

Hydrazide building blocks and hydrazide modified biomolecules

InactiveUS7129229B2Improve versatilityHigh immobilization rateBiocideDiaryl/thriaryl methane dyesHydrazideSubstrate surface

This invention relates to attachment chemistries for binding macromolecules to a substrate surface or to other conjugation targets. More particularly, this invention relates to attachment chemistries involving branched or linear structures having one or more hydrazide attachment moieties for binding the macromolecules to a substrate surface, or for other conjugation reactions. Novel modifying reagents are provided for the introduction of protected hydrazide attachment moieties or precursor forms of such hydrazides to the macromolecule, either as a single hydrazide or as multiple hydrazides.

Owner:SANOFI AVENTIS SA

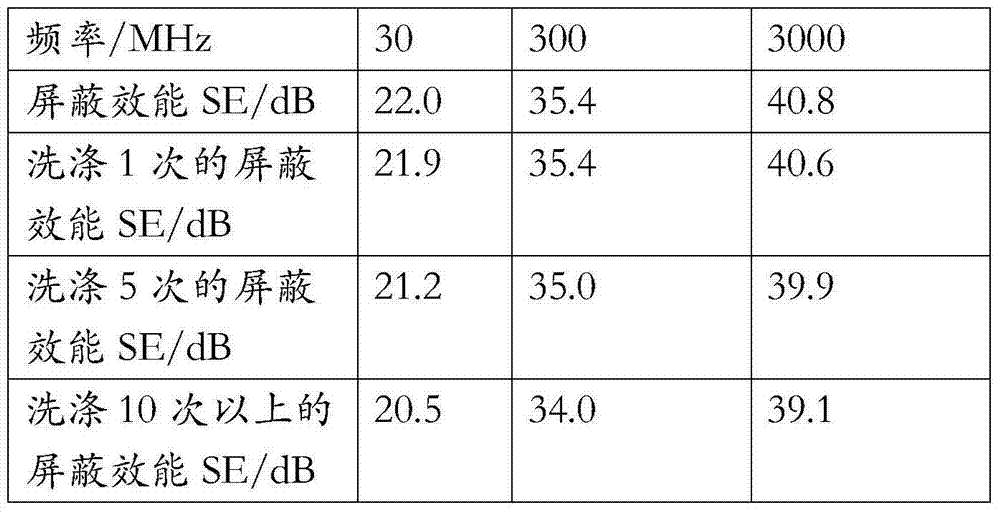

Method for chemically treating sludge and application

InactiveCN108862947APromote harmless natural degradationGood mechanical propertiesSludge treatment by oxidationSolid waste managementChemical treatmentEcological environment

The invention discloses a method for chemically treating sludge and application. The method comprises the following steps: placing sludge in a stirring tank, adjusting the water content to 20 to 99 percent, and obtaining sludge slurry; and adding a macromolecular binding material, a sludge improver and a functional additive into the sludge slurry A, mixing, stirring, introducing gas, and obtaininga sludge purificant. According to the requirements of an application field and an application objective, a porous solid product with excellent mechanical performance can be obtained by spraying, smearing, salivating, filling, and irrigating the sludge purificants, the product has no dissolved sludge and is unlikely to scatter, so that the product is convenient to store and transport and light andsanitary to use; and in addition, after being cured, the sludge purificants are porous, permeable, hydrophilic, capable of retaining water, and sufficient in nutrition, capable of providing a good root ecological environment to the plant and capable of promoting the harmless natural degradation of the sludge, before the treatment, the sludge does not need to be settled, filtered, calcined or buried, so that the problems of the traditional sludge treatment method that the energy consumption is large, the period is long, the cost is high, and the procedures are complicated and the like can be solved.

Owner:南京耀珂新材料科技有限公司 +1

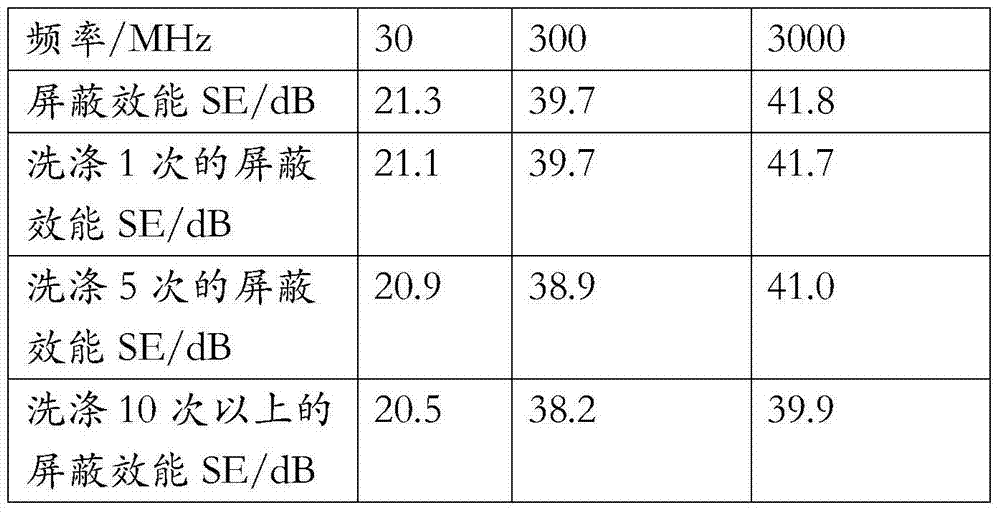

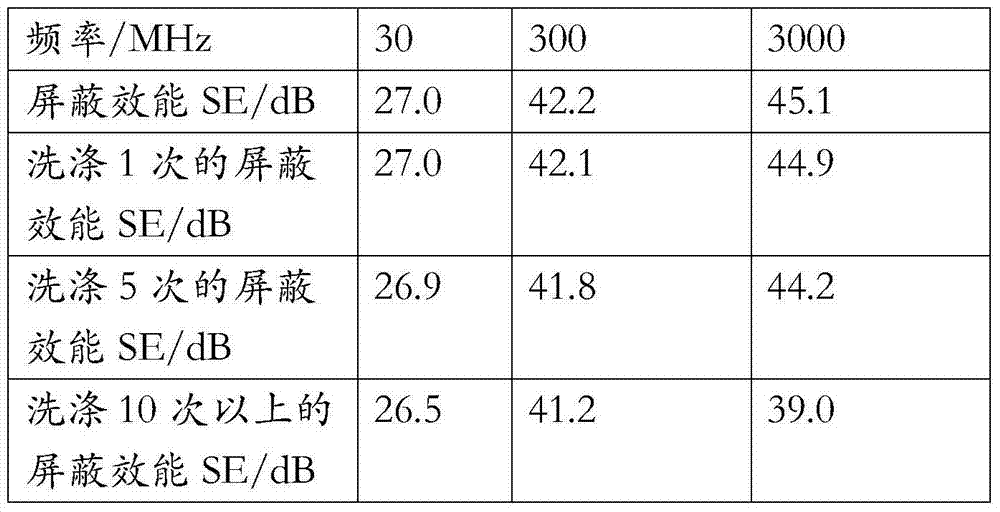

Anti-radiation finishing processing method for fabric

ActiveCN103898736AHigh strengthTo achieve the purpose of bondingFibre treatmentLiquid/gas/vapor textile treatmentCooking & bakingGram

The invention provides an anti-radiation finishing processing method for a fabric. The anti-radiation finishing processing method is characterized in that a padding and baking process is used for attaching nano magnetic metal to the fabric, wherein each liter of a padding working solution contains following substances in mass: 30-60g / L of a nano metal wave absorbing agent and 40-60g / L of a macromolecular binding agent. Cloth produced by the anti-radiation finishing processing method avoids the defects of poor washing fastness, great gram weight, poor flexible comfort and the like; meanwhile, the fabric is used for absorbing electromagnetic waves and converting the electromagnetic waves to heat to release heat; the fabric is more superior than a fabric which reflects the electromagnetic waves; furthermore, the special macromolecular binding agent is used and a nano magnetic metal material is finished on the fabric by a special process to produce the fabric with soft hand feeling, good washing fastness and good anti-radiation effect; the method can be used for producing thin and light spring and summer anti-radiation fabrics.

Owner:SHANGHAI JIALE

Antibiotic, moisture-absorption, flavor-removing, health care mask

InactiveCN101455449AAntibacterialHygroscopicRespiratory apparatusProtective garmentSurface layerFiltration

The invention is manufactured for aiding in removing moisture, smell and bacterial when people wear masks, in the meantime, is able to release negative ions and infrared ray that are favorable for human body, and provides a formulation of raw materials for an antibiotic, moisture-absorbing, smell-eliminating and healthcare mask and a production process thereof, the formulation of raw materials thereof includes: macromolecular binding agent, bamboo charcoal powder, surfactant and polypropylene fiber film. The proportion in the formulation of raw materials of the mask is as below: 10-50% of macromolecular binding agent, 0.1-30% of bamboo charcoal powder, 0.1-20% of surfactant and 1-10% of polypropylene fiber film. The process flow of the mask includes the steps of: adding a polypropylene fiber film interlayer into a filtration layer of the mask; then binding the bamboo charcoal powders using the macromolecular binding agent to form a bamboo charcoal powder layer as a surface layer of the mask, afterwards, adding the surfactant on the surface layer thereof; eventually, combining the layers of the mask together by a mechanically sewing process.

Owner:冯玉

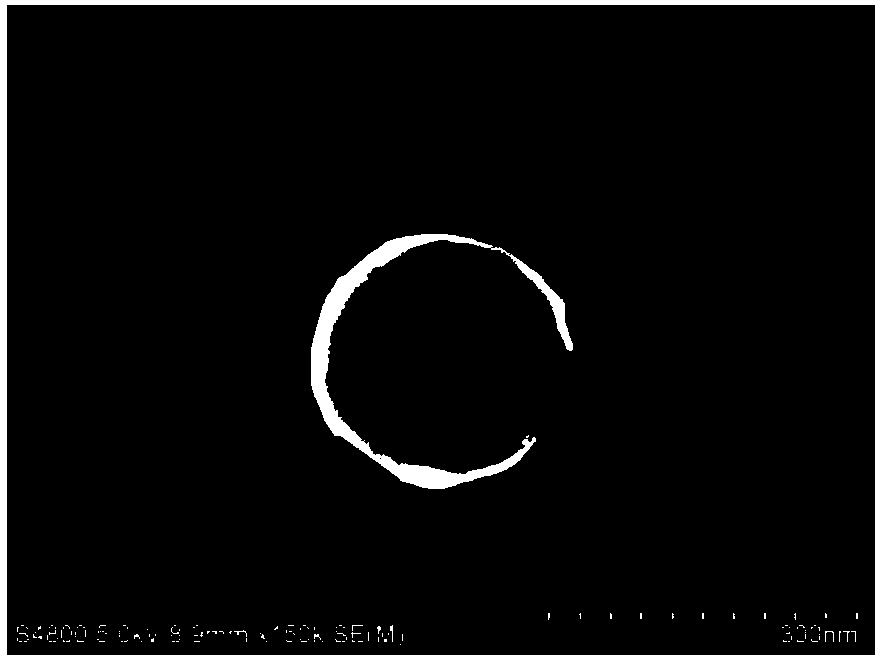

Method for preparing TiO2@Au core-shell structure in template method

InactiveCN107597110AAvoid gatheringGood monodispersityMetal/metal-oxides/metal-hydroxide catalystsBiological macromoleculeCore shell

The invention discloses a method for preparing TiO2@Au core-shell structure in a template method. The method comprises the following steps: preparing PS@Au in a template method, coating the PS@Au witha layer of amorphous titanium dioxide to obtain TiO2@PS@Au, and calcining the TiO2@PS@Au to obtain TiO2@Au. PS is used as a template, Au is wrapped in the TiO2, a uniform and stable TiO2@Au core-shell structure can be obtained after the calcinations, and the dispersion property is good. The core-shell structure is a hollow structure, the weight is light, and the surface area is relatively large under the same mass. Nano gold can be combined with various biological macromolecules, the bioactivity is not influenced, the nano gold can be applied to the biological catalysis and biological sensing, the TiO2@Au obtained by the invention can be used as an enzyme reactor, compared with the method only adopting the pure titanium dioxide as the carrier, the separation of the nano gold in the subsequent reaction can be avoided, the advantages of the titanium dioxide semiconductor can be played, and the overall catalytic efficiency can be increased.

Owner:WUHAN UNIV OF TECH

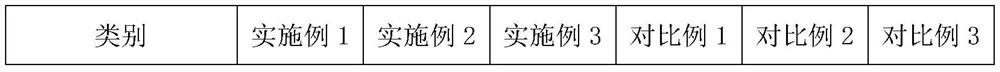

High-performance polyurethane for reaction injection molding and preparation method thereof

The invention provides a high-performance polyurethane for reaction injection molding and a preparation method thereof. The high-performance polyurethane for reaction injection molding is composed of a component A and a component B. The component A comprises the following raw materials in parts by weight: 70-85 parts of polyester polyol, 10-15 parts of modified attapulgite, 3-5 parts of chain extender and 1-3 parts of composite catalyst. The component B comprises the following raw materials in parts by weight: 80-90 parts of isocyanate, 5-8 parts of foaming agent and 1-3 parts of antiaging agent. The mass ratio of the component A to the component B is 10:(5-7). The modified attapulgite is utilized to modify the polyurethane so as to increase the compatibility between the attapulgite and polyurethane material; a surfactant is utilized to modify the attapulgite so as to increase the surface area, and the modified attapulgite is combined with macromolecules to form the network structure; when the polymer is subjected to external force, the stress concentration can be changed, and a certain deformation energy can be absorbed, thereby preventing the destructive cracking, and enhancing the comprehensive properties of the polyurethane material.

Owner:浙江吉高新材料有限公司

Method for producing tobacco leaf fermenting enzyme preparation

InactiveCN101144074AIt has the characteristics of high temperature resistance of rebaking lineHas high temperature propertiesTobacco treatmentEnzymesBiotechnologySaccharum

The present invention relates to a novel tobacco fermenting enzyme preparation production method. The purpose is to solve the technical problems that how improve the quality of the tobacco fermenting product is improved and how the reactivity protection of the tobacco fermenting enzyme preparation is realized in the natural fermenting field of tobacco. The enzyme preparation consists of a glucoseoxidase, a chlorophyl oxidase, a carotenoid oxidase, a protease, and a nicotine-degradation enzyme. Through the cell disruption of fresh leaves, (NH 4) 2 SO 4 is utilized to operate the second fractional precipitation to obtain crude enzyme fluid, an enzyme molecule adopts Ca 2 + and Mg 2 + to operate the metal ion exchange, to accomplish the molecule modification; a macro molecule combination modification is accomplished through adopting 0.01 percent of cane sugar low molecular polymer, thereby prolonging the half life period of theenzyme preparation and obviously improving the high temperature resistant ability. The experimental result employed by the enzyme preparation indicates that the nicotine is decreased by 9.3 percent, the total nitrogen is decreased by 5.7 percent, the protein is decreased by 7.1 percent; cigarette smoke condensates are decreased by 8.4 percent, the tar content is decreased by 5.1 percent, the cigarette smoke nicotine content is decreased by 28.0 percent, and the carbon monoxide is decreased by 1.6 percent. The enzyme preparation is employed when the tobacco leaf is wet for the second time before defolat and redrying.

Owner:云南万芳生物技术有限公司 +2

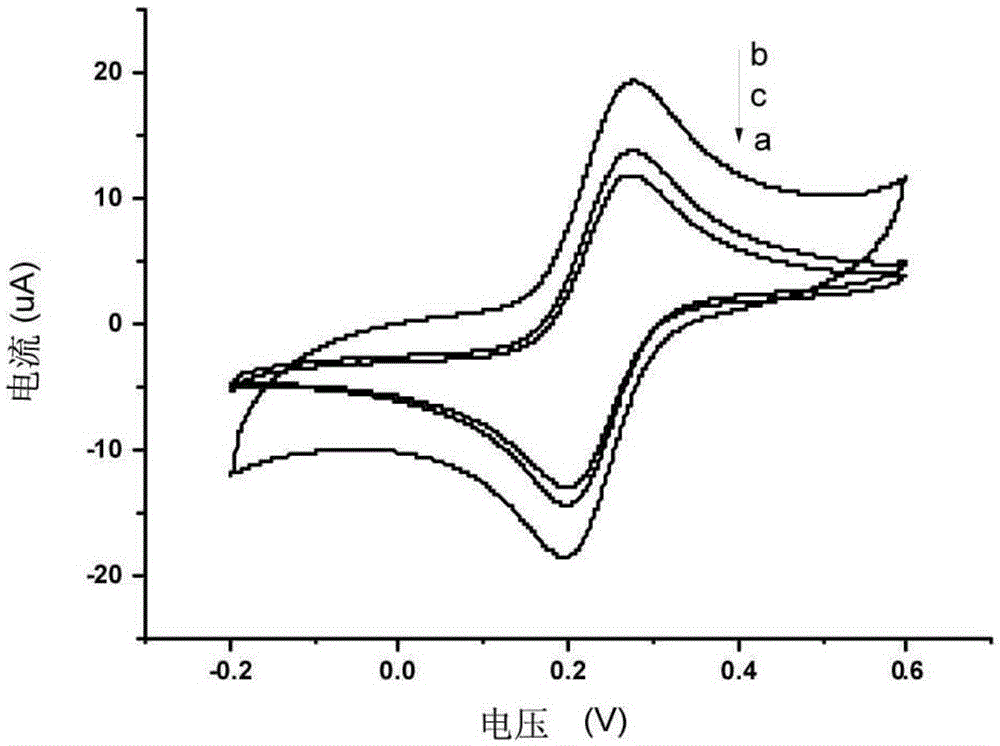

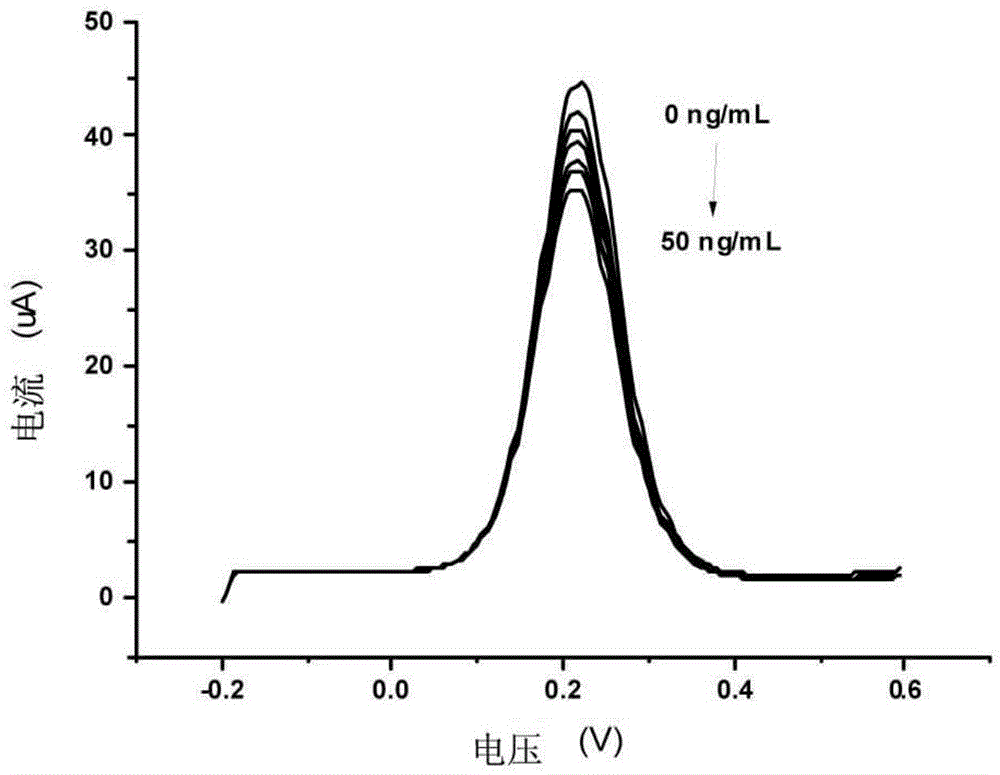

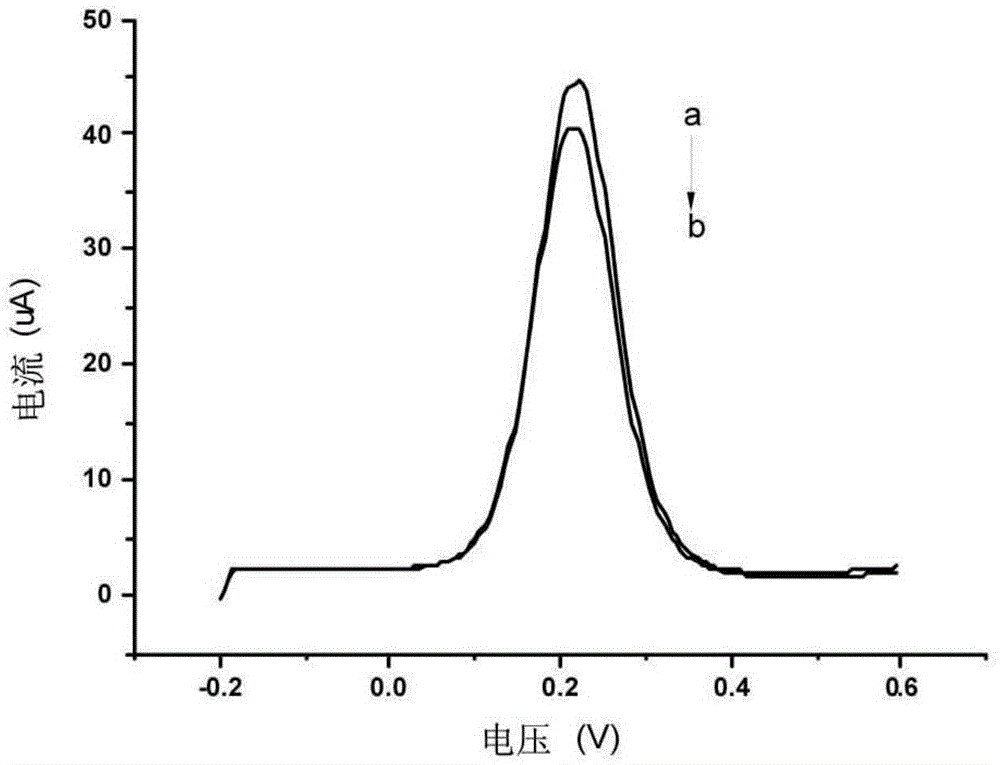

Preparation method and detection method of nano-immunosensor used for rapidly detecting benzo(a)pyrene

InactiveCN105486741AShorten inspection timeImprove detection efficiencyMaterial electrochemical variablesDendrimerPolycyclic aromatic hydrocarbon

The invention belongs to the technical field of rapid detection of food safety, and particularly relates to a preparation method and a detection method of a nano-immunosensor used for rapidly detecting benzo(a)pyrene. The preparation method includes the steps that a glassy carbon electrode serves as a basic electrode, a polyamide-amne dendrimer is combined with poly(diallyldimethylammonium chloride) functionalized graphene for modifying the glassy carbon electrode, then a nano-gold solution is dispensed, nano-gold is immobilized to the modified electrode under the electrostatic adsorption effect, and then a polycyclic aromatic hydrocarbon antibody is immobilized through glutaraldehyde coupling to prepare the nano-immunosensor. The nano-immunosensor is used for detecting benzo(a)pyrene in food; a result obtained through the detection method is consistent with that obtained through a national standard method, but the detection method for benzo(a)pyrene is high in sensitivity and accuracy, short in detection time, simple and convenient and fast to implement and has broad application prospects.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

AGROCHEMICAL DELIVERY SYSTEM BASED ON ENZYME- OR pH- RESPONSIVE AMPHIPHILIC PEG-DENDRON HYBRIDS

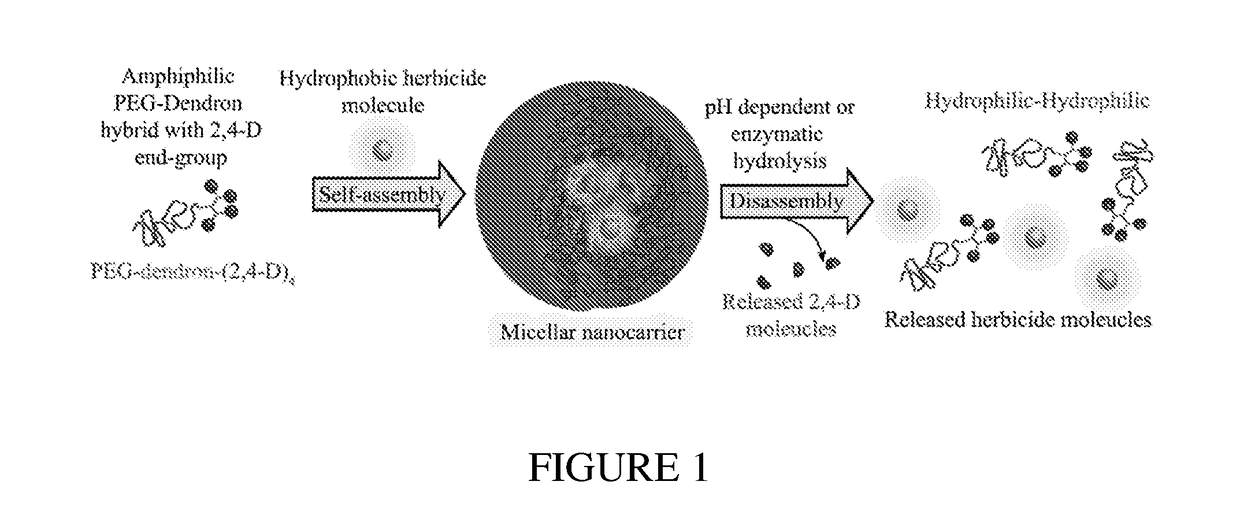

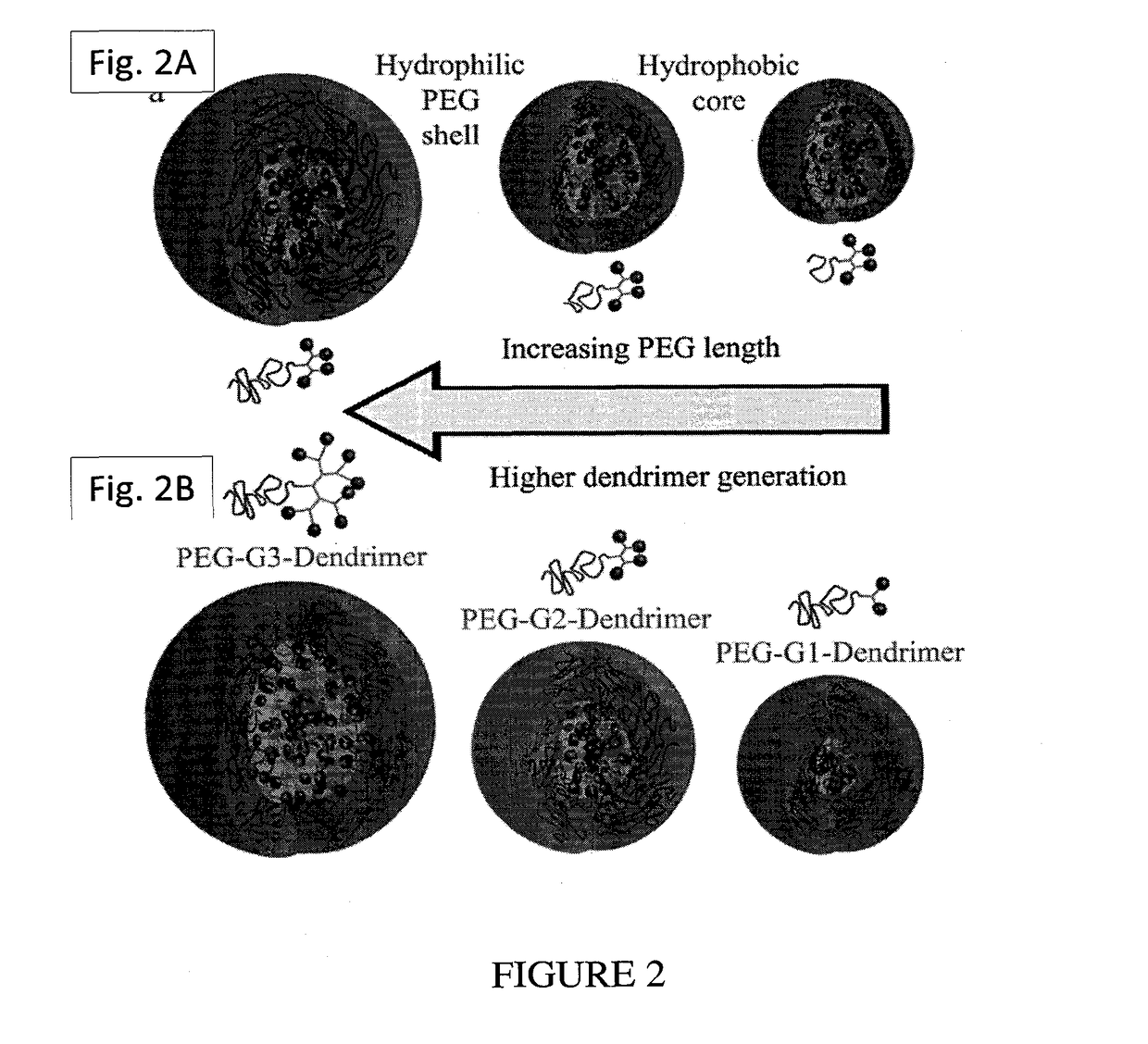

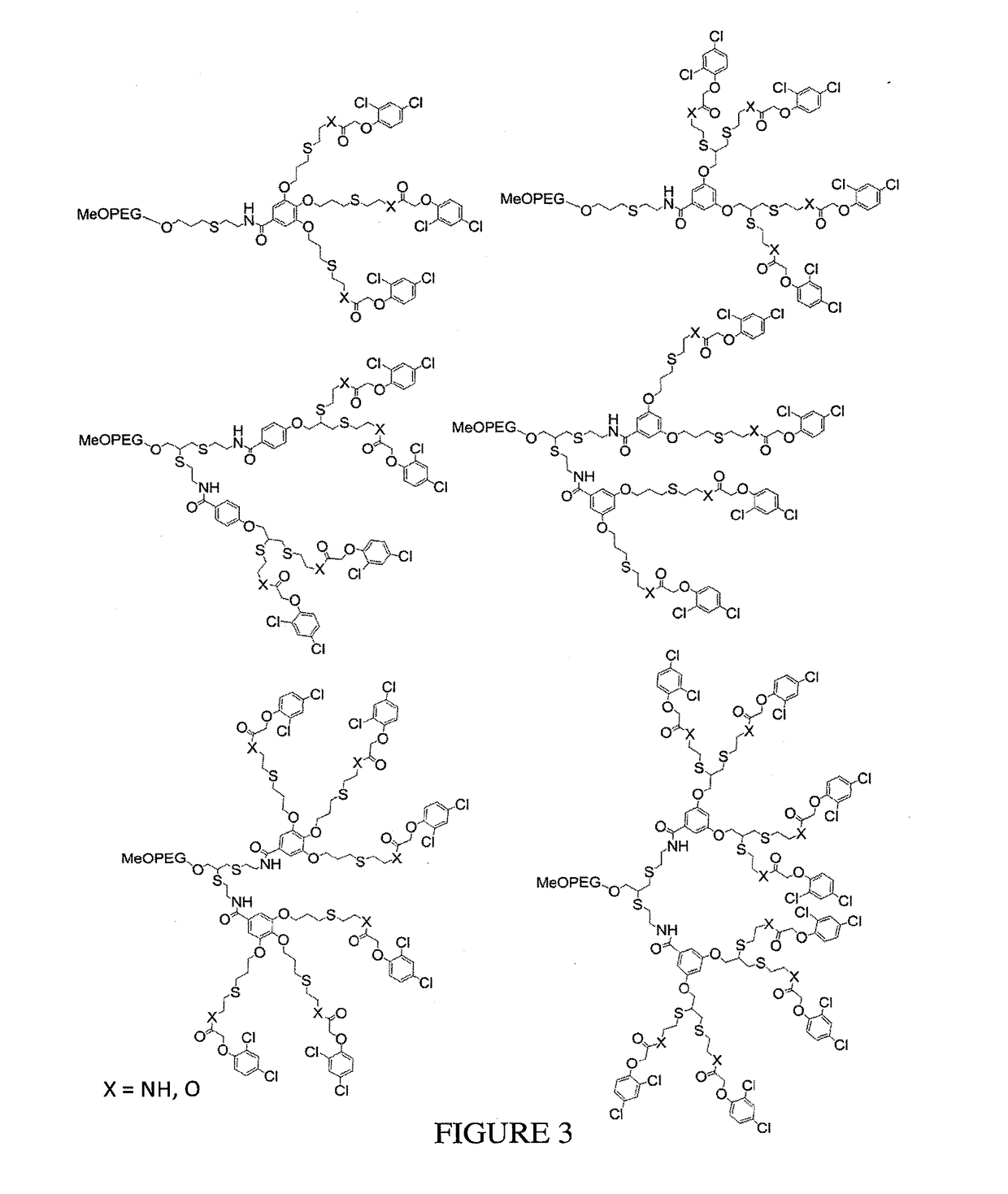

InactiveUS20170245492A1Avoidance of nonspecific activationMore hydrophilicBiocideAnimal repellantsEnd-groupPolyethylene glycol

The present invention relates to an amphiphilic hybrid delivery system in micellar form for delivery of agrochemicals, based on a hydrophilic polyethylene glycol (PEG) polymer conjugated to a hydrophobic dendron, the dendron comprising at least one pH-dependent or enzymatically cleavable hydrophobic end group that is covalently attached to the dendron, wherein the micelle disassembles upon enzymatic or pH-dependent cleavage of the hydrophobic end group. The hydrophobic end group that is conjugated to the dendron may comprise an agrochemical, and / or the micelle may (non-covalently) encapsulate an agrochemical. The present invention further provides methods of use thereof and to a kit comprising same.

Owner:RAMOT AT TEL AVIV UNIV LTD

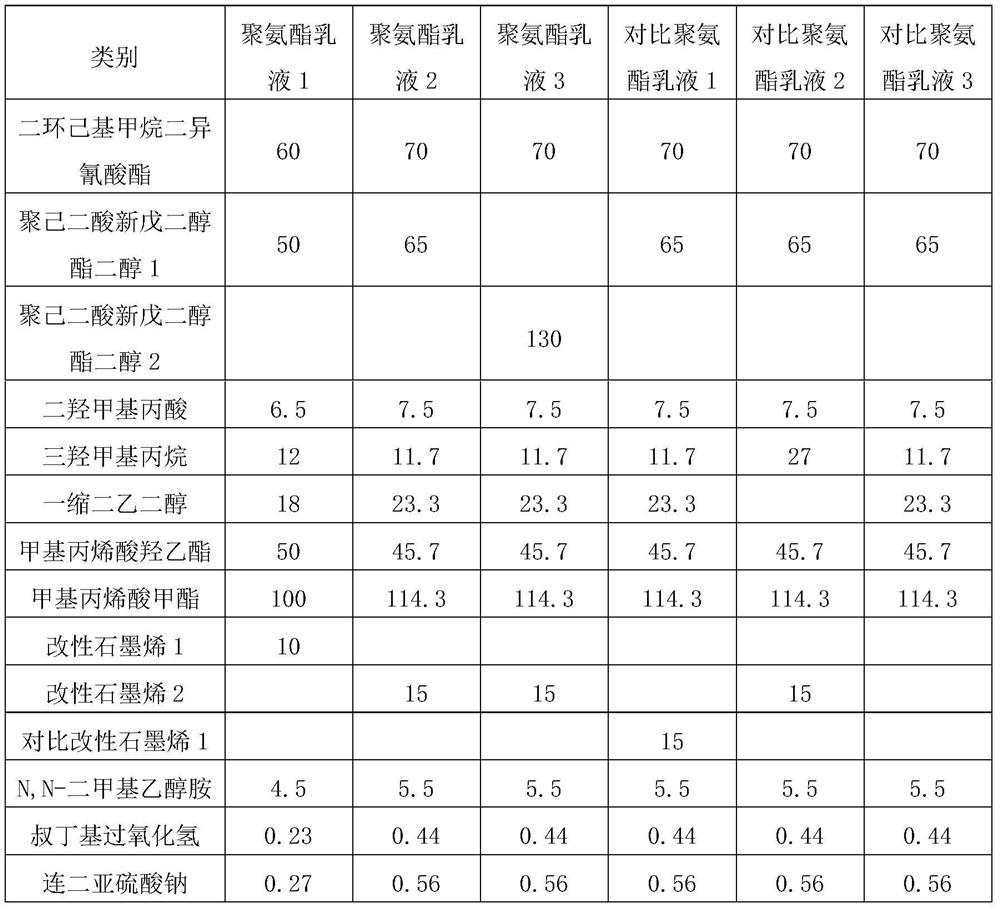

Novel water-based graphene polyurethane coating and preparation method thereof

InactiveCN112876934AGood mechanical propertiesStrong adhesionAnti-corrosive paintsPolymer science(Hydroxyethyl)methacrylate

According to the novel waterborne graphene polyurethane coating provided by the invention, modified graphene is added into raw materials of the coating, the modified graphene is modified through hydroxyethyl methylacrylate and diethylene glycol, and hydroxyl and unsaturated double bonds are grafted on the surface of the modified graphene, so that on one hand, dispersion of graphene in the coating can be promoted; and on the other hand, the polyurethane emulsion can be combined with macromolecules in the polyurethane emulsion, so that the finally prepared coating has excellent comprehensive performance. In addition, the invention also provides a preparation method of the coating.

Owner:陈广洪

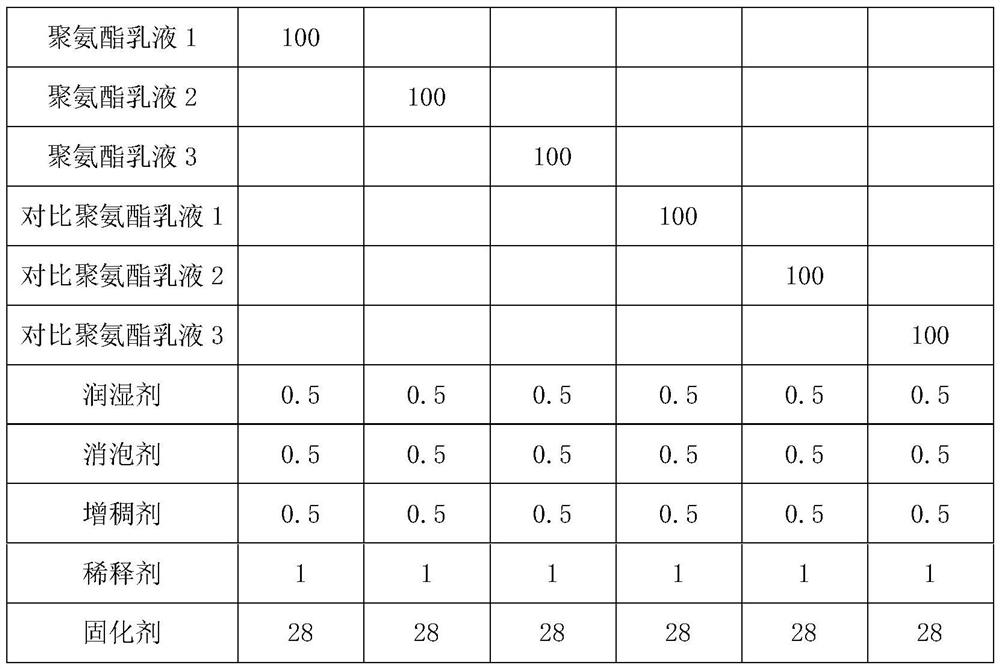

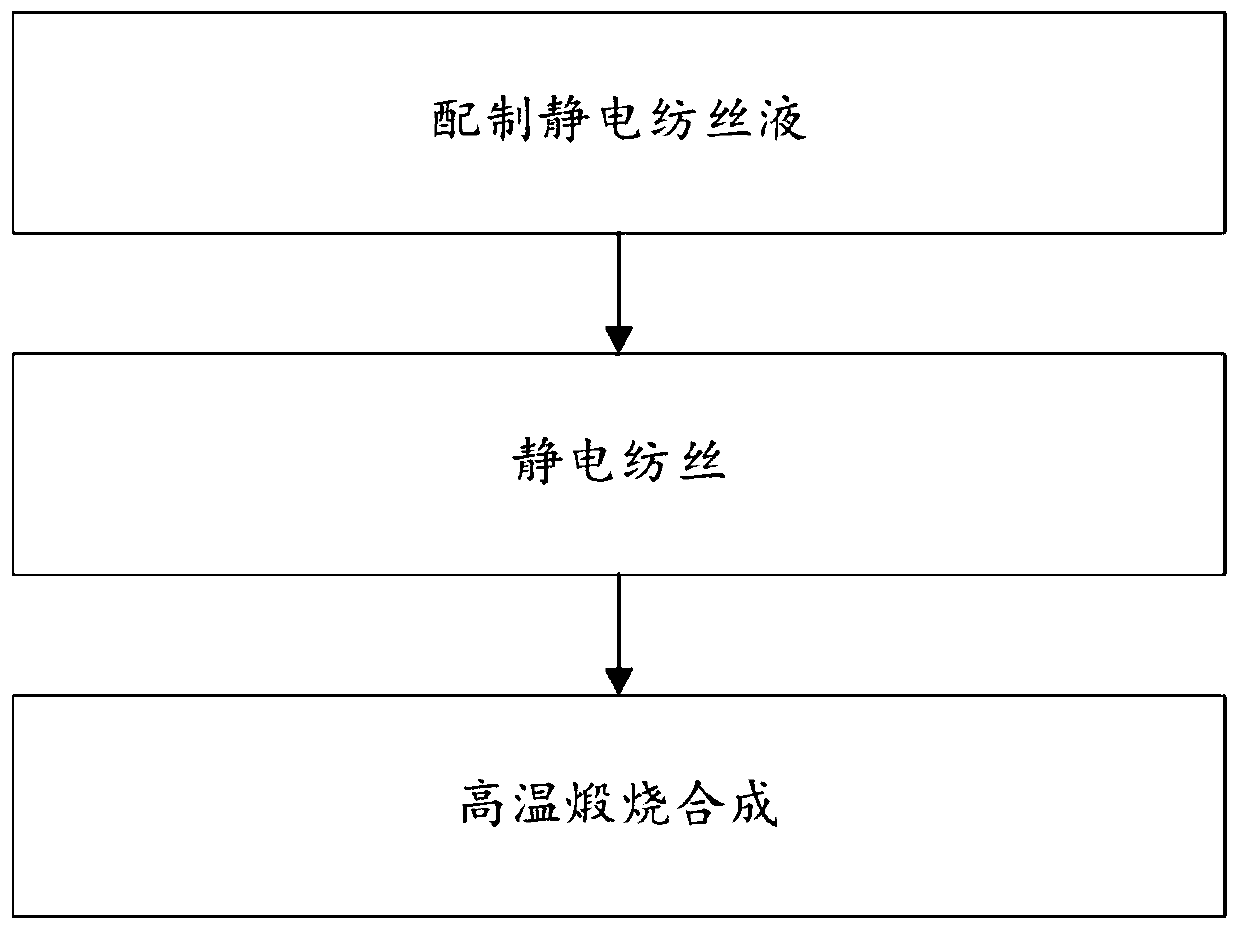

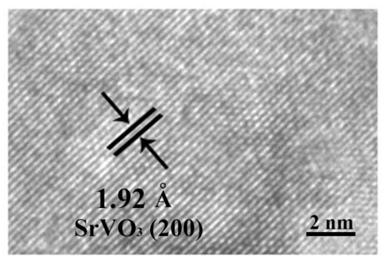

Preparation method and related products of SrVO3 nanofibers

ActiveCN111270348AThe synthesis process is simpleLow costInorganic material artificial filamentsFilament/thread formingSpinningElectrospinning

The present invention provides a preparation method and related products of SrVO3 nanofibers. The method comprises the steps of dissolving a strontium-containing soluble compound and a vanadium-containing soluble compound in a solvent, adding a macromolecular binding agent, and stirring the components uniformly to obtain an electrostatic spinning solution; transferring the electrostatic spinning solution into an electrostatic spinning device for electrostatic spinning to obtain precursor nanofibers and; putting the precursor nanofibers into air for peroxidization calcining to obtain SrO / V2O5 nanofibers, and then performing calcining in a reducing atmosphere to obtain the SrVO3 nanofibers of one-dimensional structures. The application structures of traditional block bodies and powder are changed.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

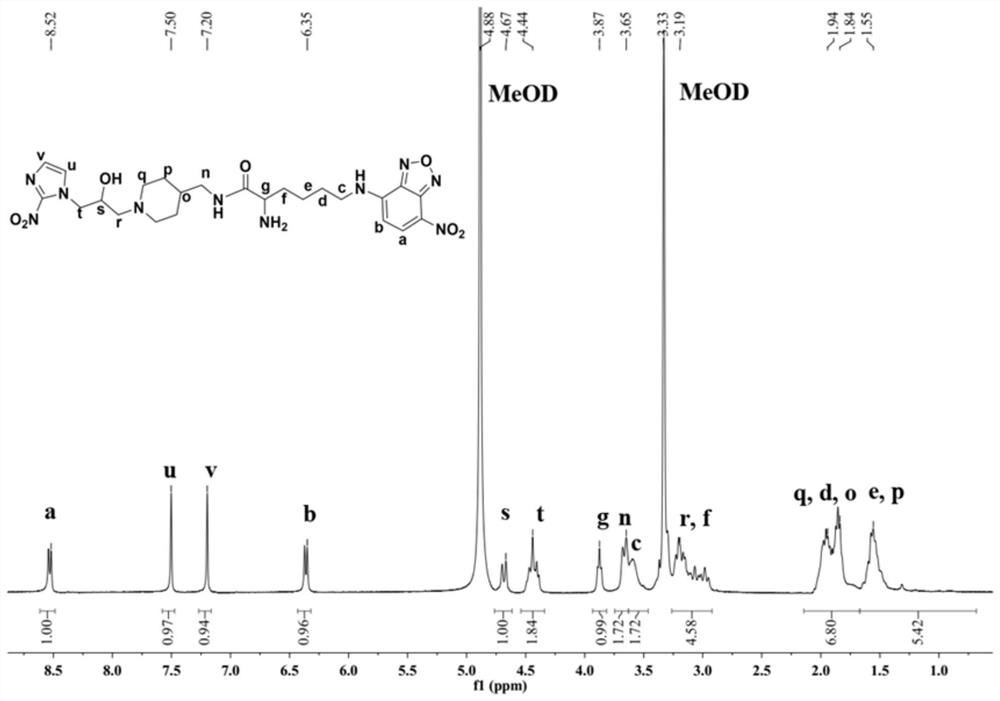

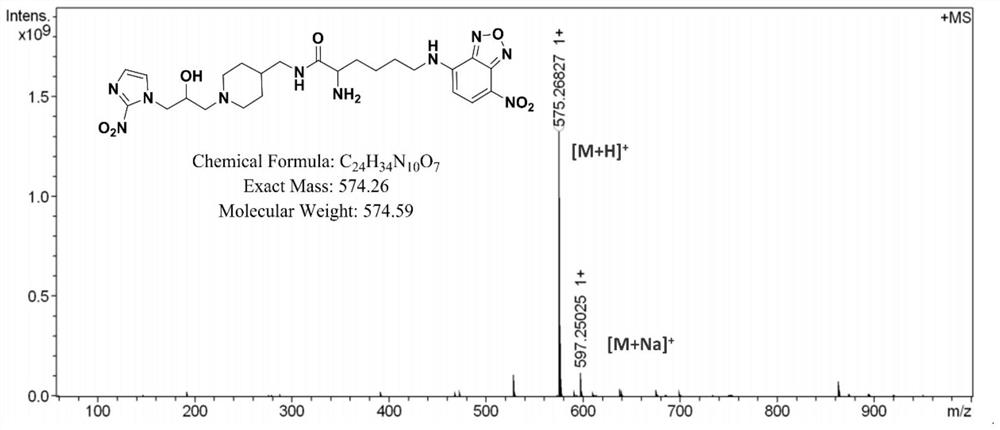

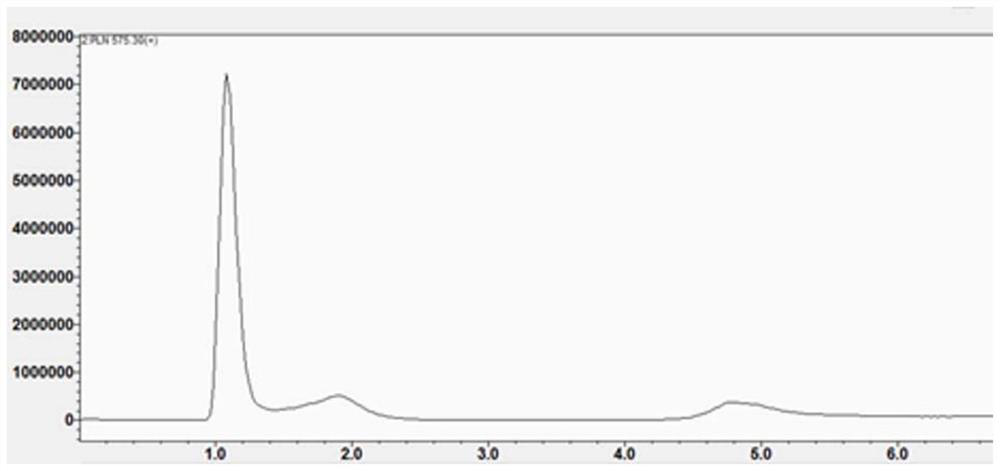

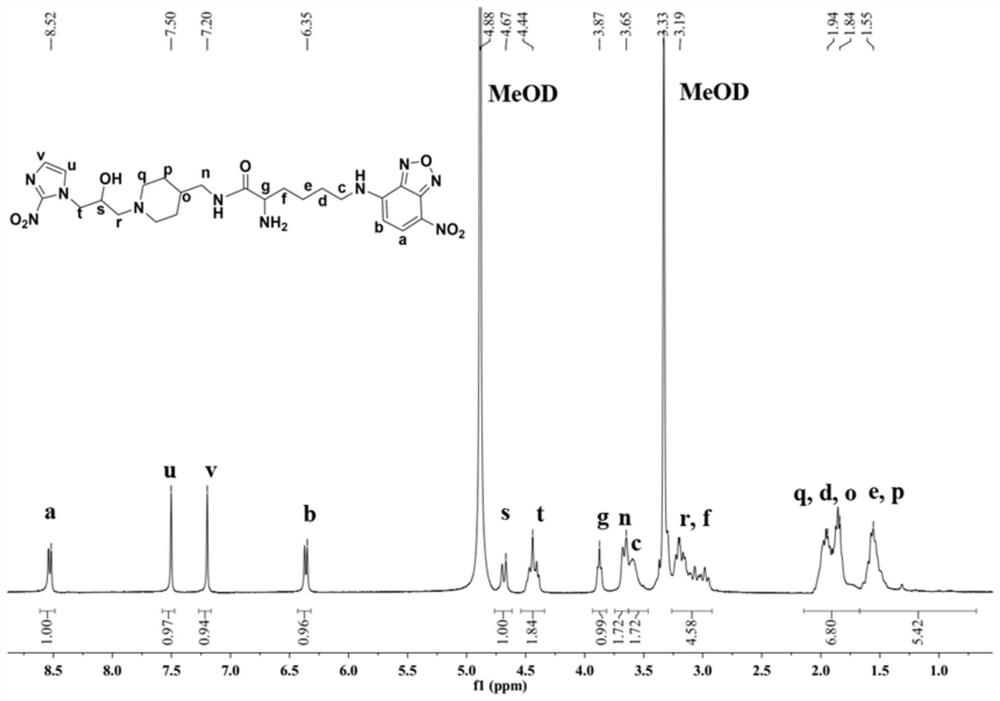

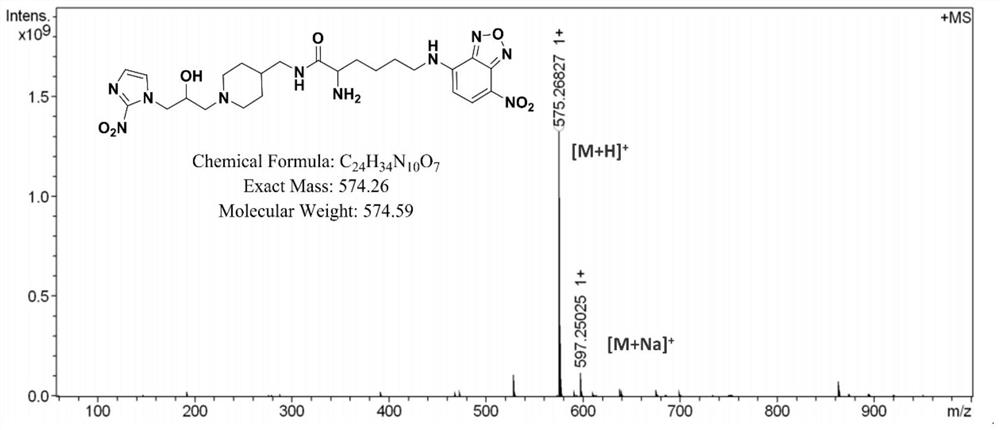

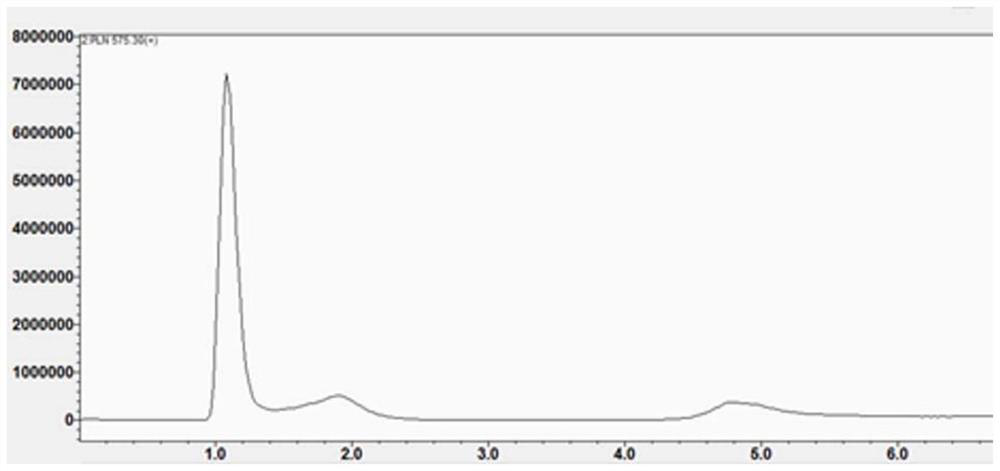

Hypoxia fluorescence imaging probe and preparation method and application thereof

ActiveCN111875597ASimple structureMeet the purpose of performing multiple functionsOrganic chemistryFluorescence/phosphorescenceNitroimidazoleNitrobenzene

The invention provides a hypoxic fluorescence imaging probe as well as a preparation method and application thereof, wherein the hypoxic fluorescence imaging probe has a structure as shown in a formula I, and is named as 1-(1-(2-nitroimidazole)-3-[(4-aminomethyl)-azacyclohexane]-2-propanol)-6-(4-nitrobenzo-2-oxa-1,3-diazole)-lysine, PLN for short; the probe disclosed by the invention can realize specific fluorescence imaging of hypoxic cells by virtue of different macromolecular combinations in different hypoxic environments by virtue of nitroimidazole groups; furthermore, the primary amino groups in the molecules are beneficial to further modification of the molecules.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Magnetic nano-composite with antioxidant function and preparation method of magnetic nano-composite

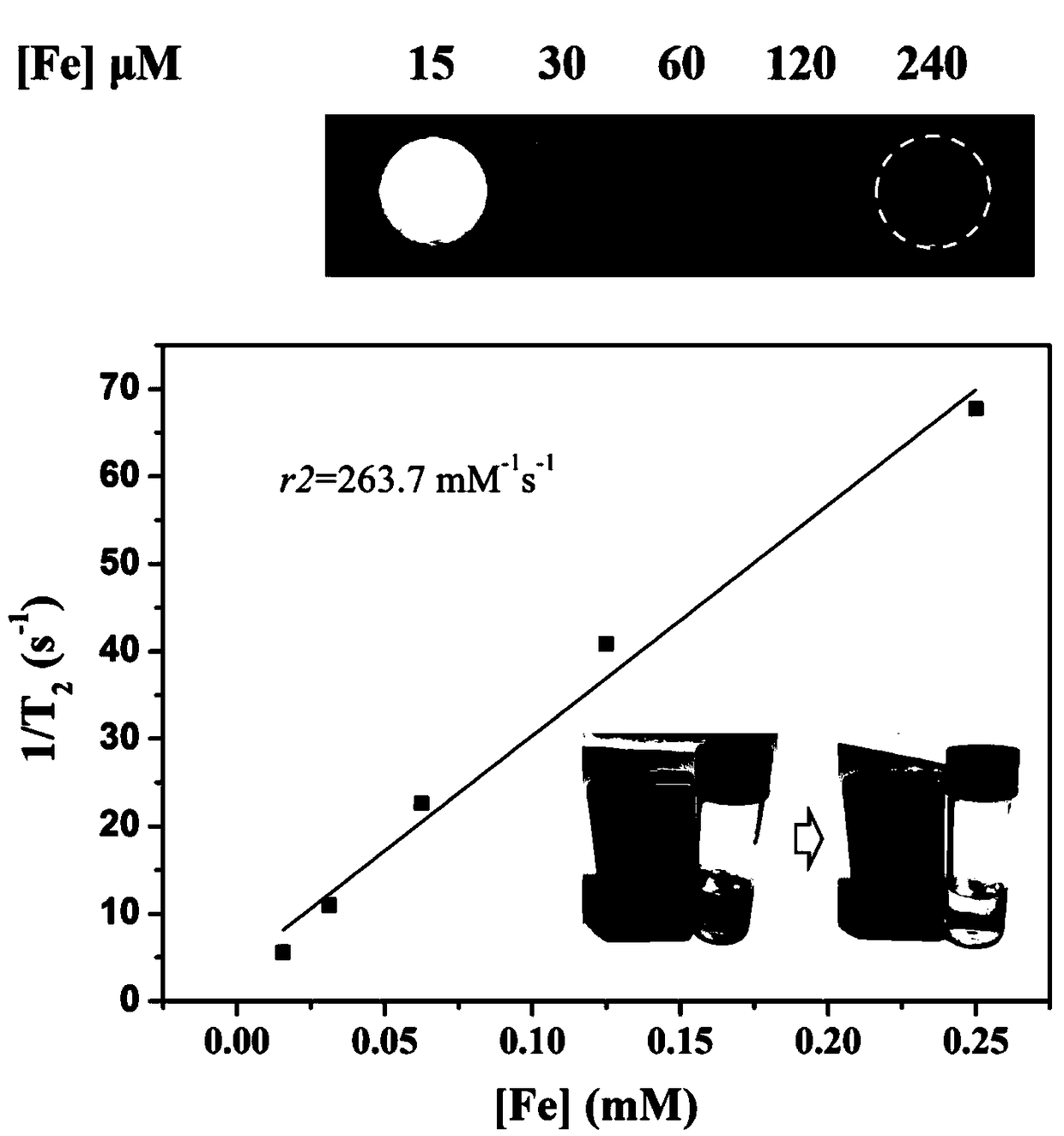

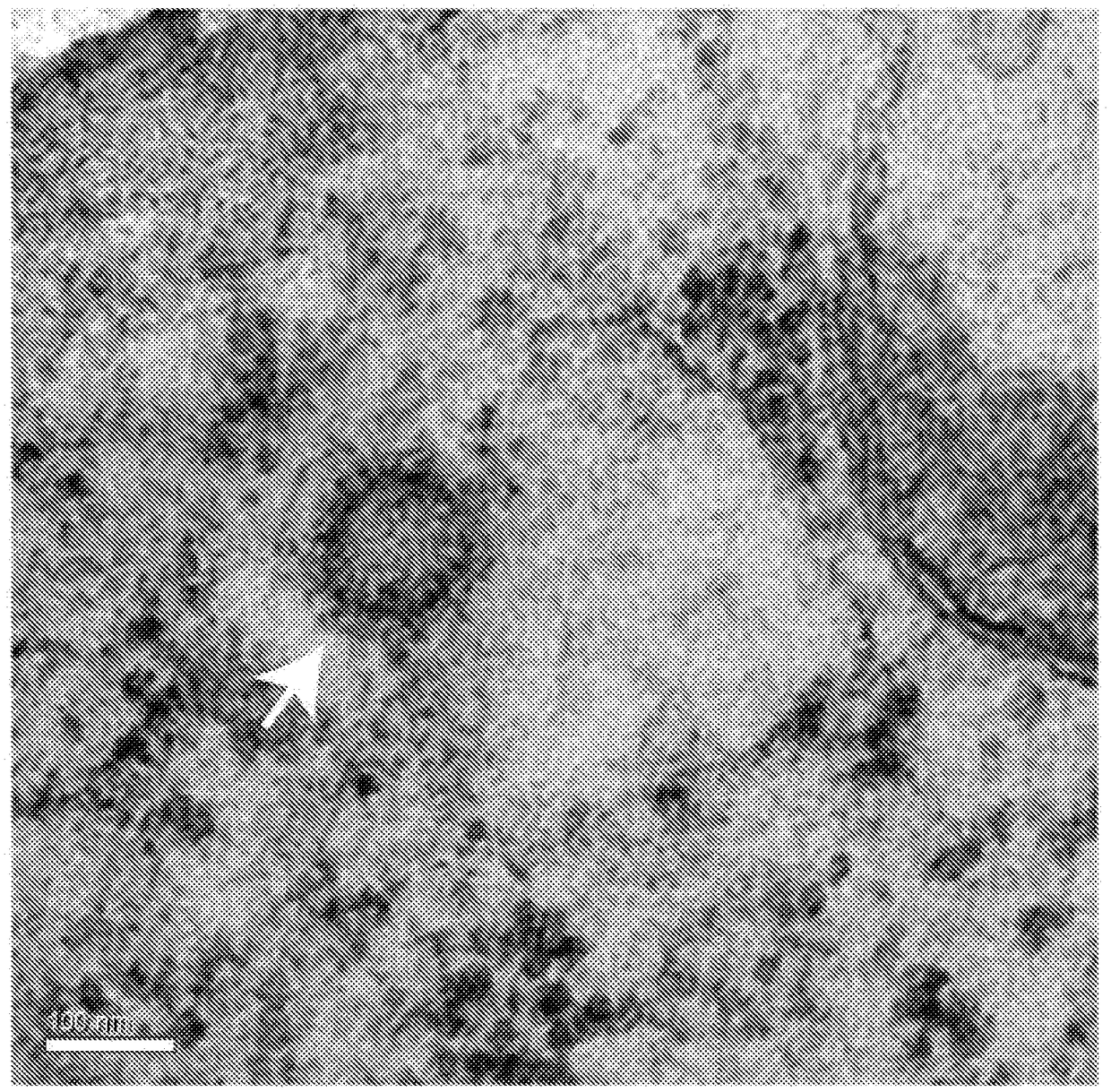

ActiveCN109395103AAchieve antioxidant functionAchieving Magnetic Resonance Imaging PerformanceOrganic active ingredientsAntinoxious agentsSolubilityMedical product

The invention discloses a magnetic nano-composite with an antioxidant function and a preparation method of the magnetic nano-composite, and belongs to the technical field of medical products. Magneticnanoparticles and amphipathic hyperbranched macromolecules are combined with antioxidant organic small molecule drugs to achieve magnetic performances and the antioxidant function. According to the magnetic nano-composite, a supramolecular chemical assembly method is used for performing supramolecular chemical driven self-assembly on polyethyleneimine (PEI)-graft-retinoic acid (RA) modified superparamagnetic nanoparticles and rutin molecules to obtain the magnetic nano-particle composite with the particle size of about 10nm and with the excellent antioxidant function and magnetic resonance imaging capacity. Rutin drugs with poor water solubility can be assembled with inorganic magnetic nanoparticles, and functions of the rutin drugs and the inorganic magnetic nanoparticles can be sufficiently achieved.

Owner:ACADEMY OF MILITARY MEDICAL SCI

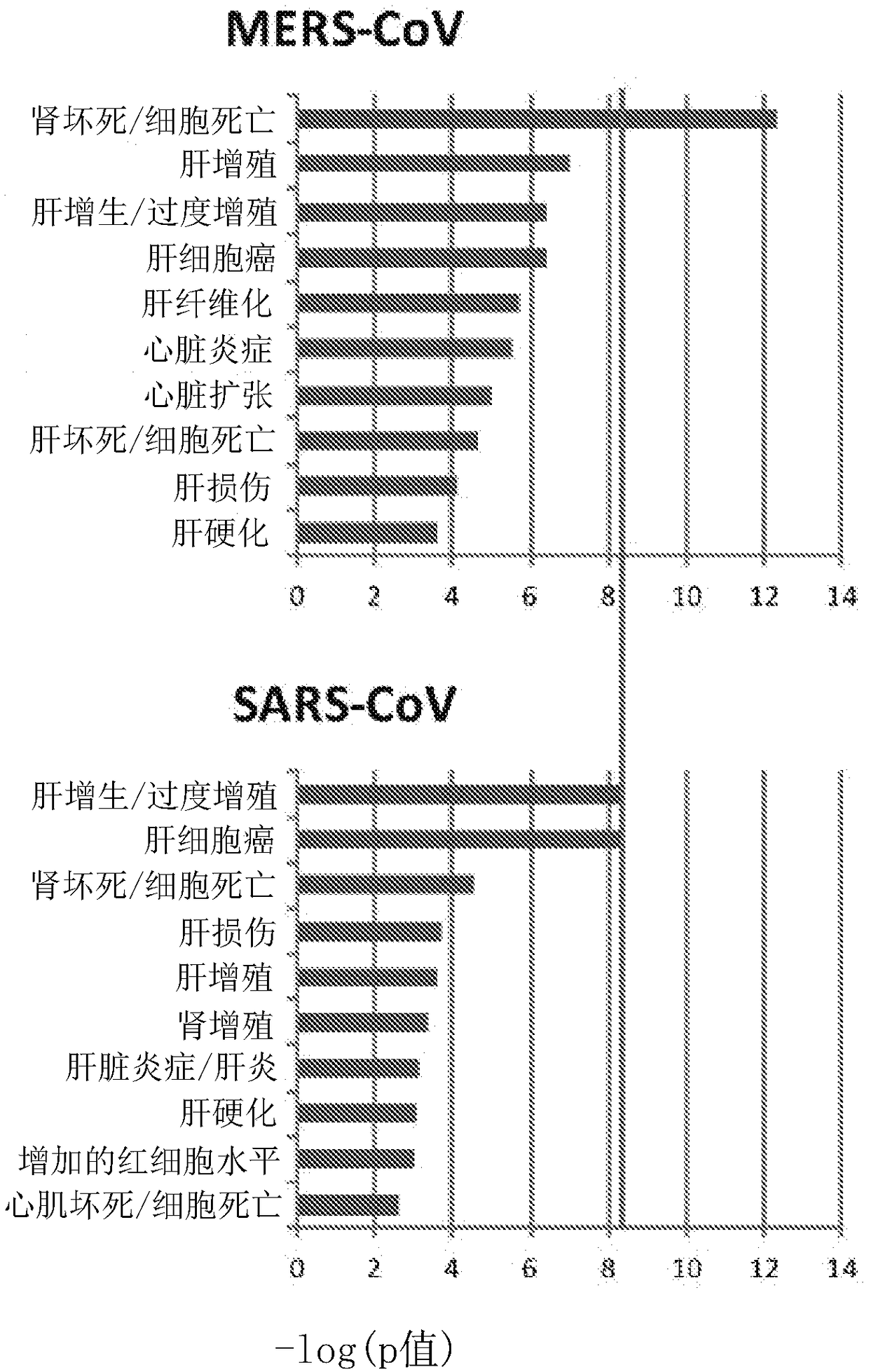

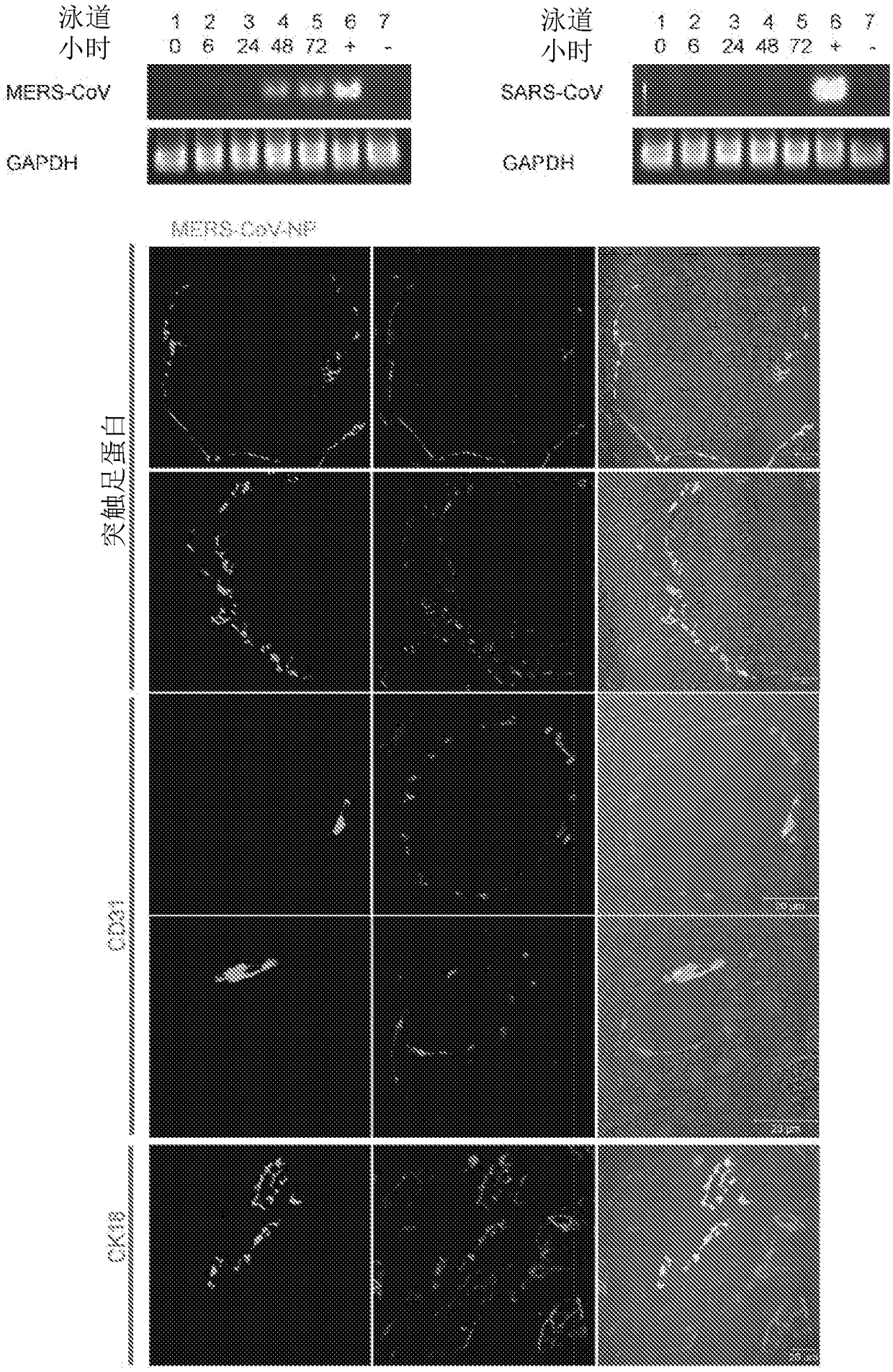

Diagnosis and treatment of mers-related renal disease

Owner:VERSITECH LTD

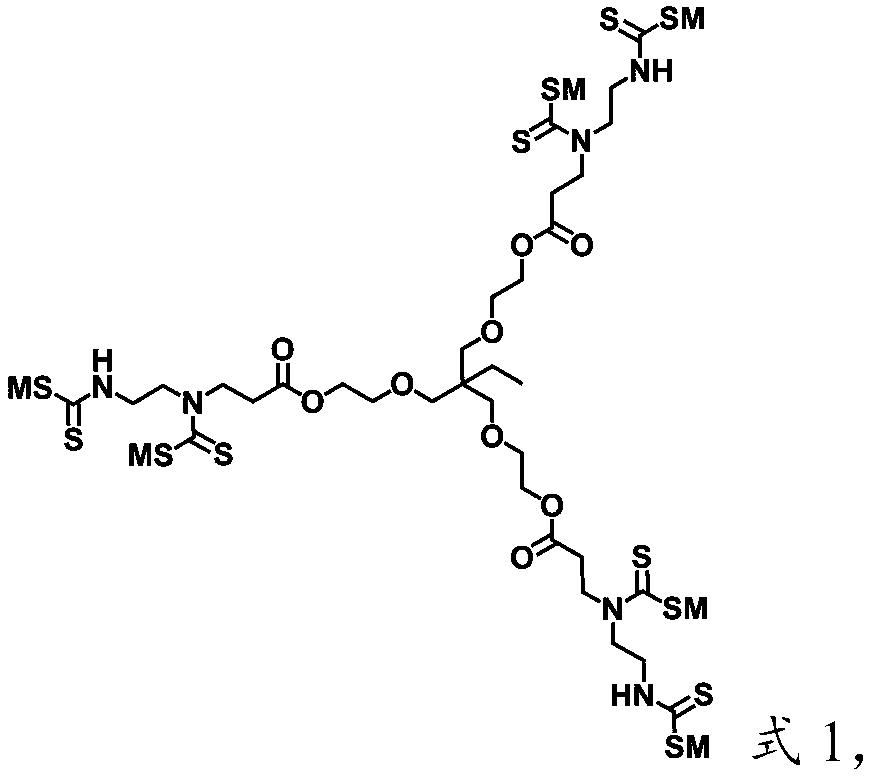

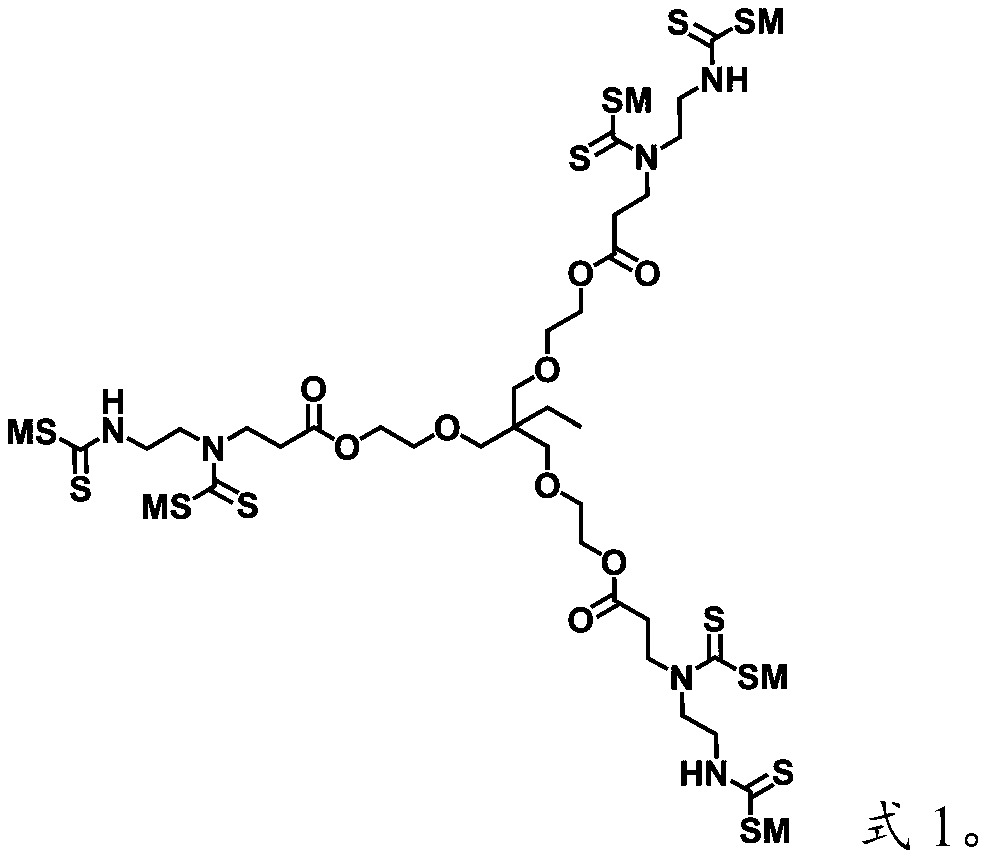

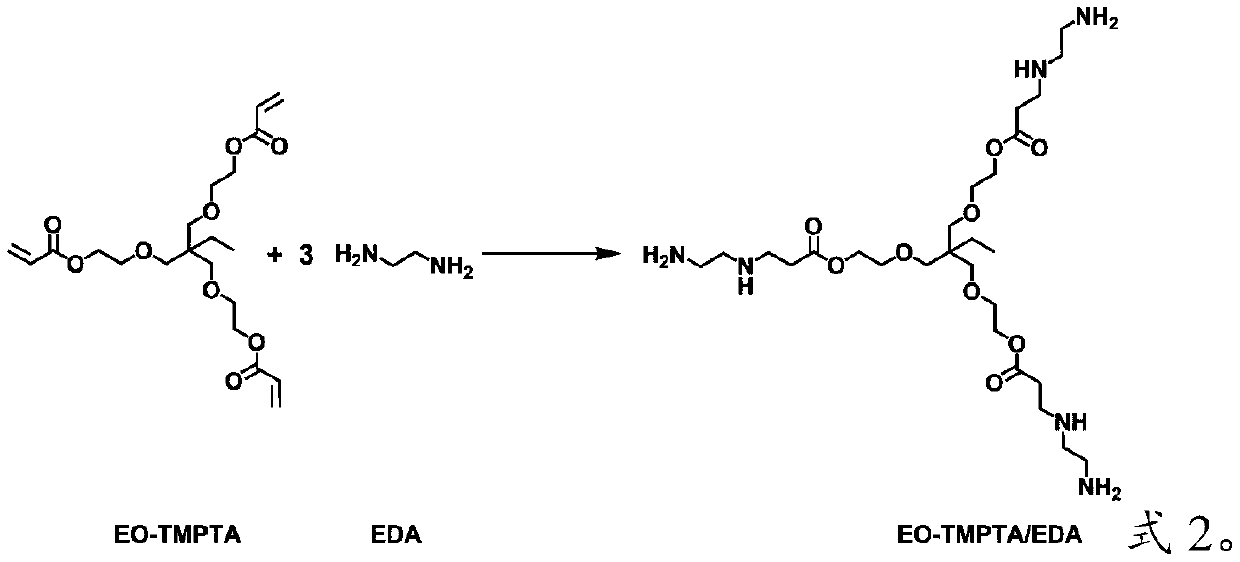

Ethoxylated trimethylolpropane core hyperbranched polymer taking dithiocarboxylate as side group and end group and application of chelating metal

ActiveCN111100052ABoth chelation and flocculation dual performanceImprove solubilityOrganic chemistryWater/sewage treatmentPolymer scienceHeavy metal chelation

The invention provides an ethoxylated trimethylolpropane core hyperbranched polymer taking dithiocarboxylate as a side group and an end group and a preparation method and application of the ethoxylated trimethylolpropane core hyperbranched polymer as a heavy metal chelating agent, and relates to the technical field of chemical engineering and environmental protection. The chemical formula of the ethoxylated trimethylolpropane core hyperbranched polymer taking dithiocarboxylate as a side group and an end group is CH3CH2C [CH2OCH2CH2OCOCH2CH2CH2N (CSSM) CH2CH2NHCSSM] 3, wherein M is Na<+>, K<+>or NH4<+>. The hyperbranched polymer provided by the invention is simple in preparation method, easily available in raw materials and easy to industrialize. The hyperbranched polymer can be used as aheavy metal chelating agent, the special three-dimensional space structure of the hyperbranched polymer can be alternately chelated with heavy metals to form a three-dimensional super-macromolecular combination with low solubility and strong stability, and wastewater and wastes containing heavy metals can be effectively treated.

Owner:TONGJI UNIV

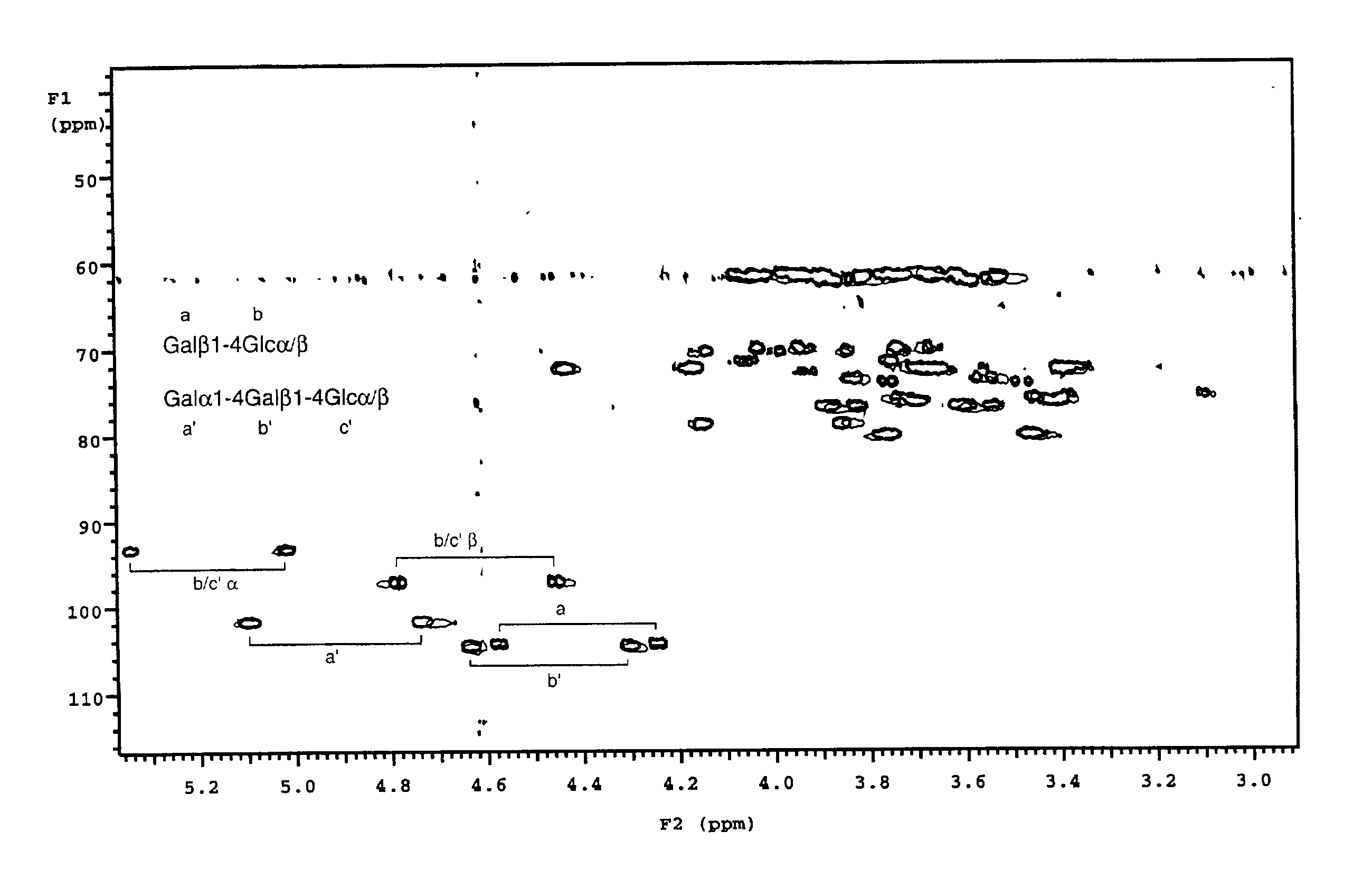

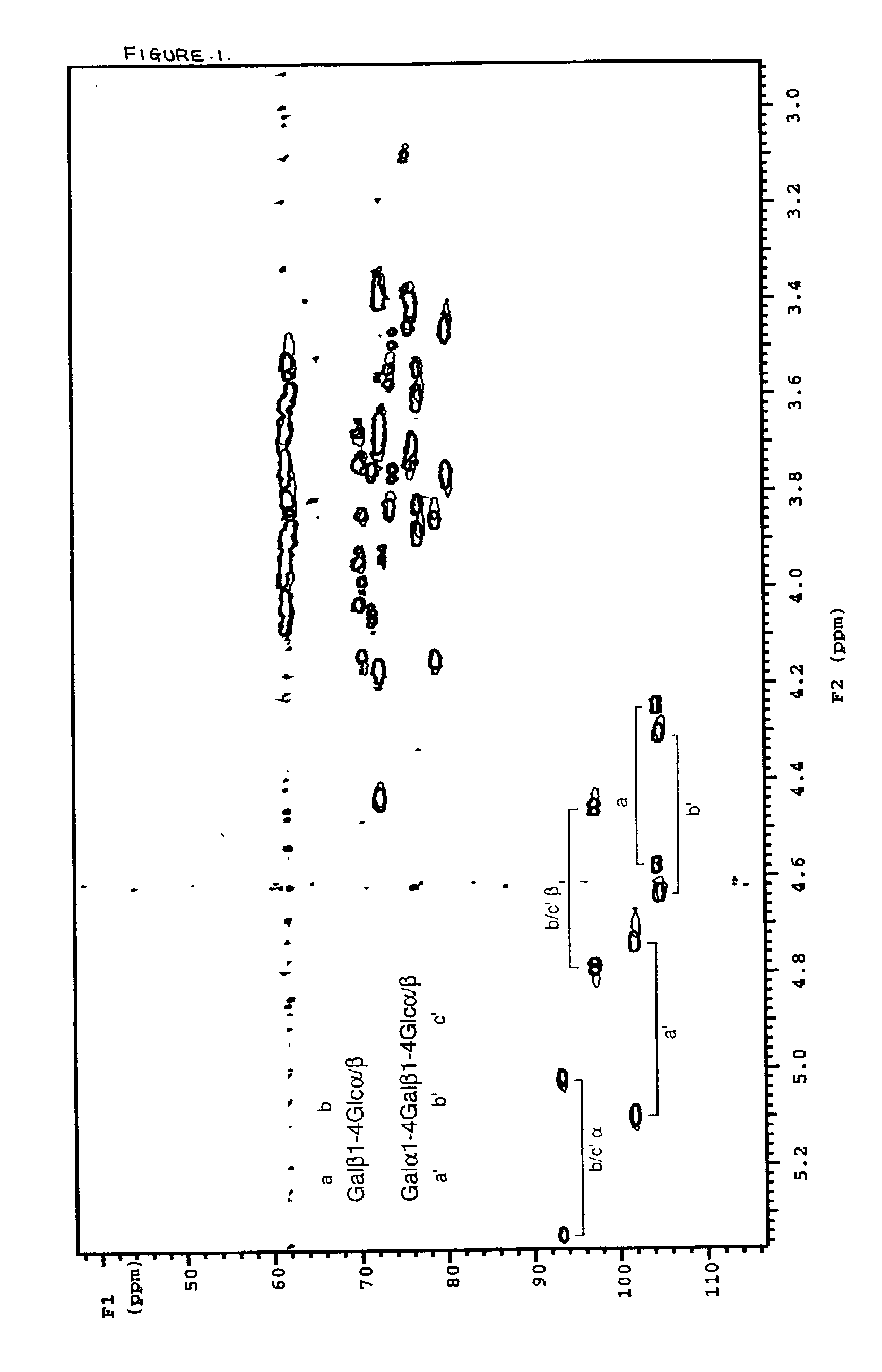

Method of screening compounds for biological activity

InactiveUS20030077628A1Small degree of orderIntuitive interpretationMicrobiological testing/measurementDrug compositionsMolecular bindingDrug biological activity

The present invention provides a method of screening compounds to identify ligands that bind to specific target molecules using nuclear magnetic resonance (NMR) and the measurement of residual dipolar couplings. The method is particularly useful in screening and / or identifying compounds which bind to specific target molecules, for example proteins, polypeptides and macromolecules so as to assist in rational drug design.

Owner:UNIV OF LEEDS

Producing method of novel tobacco fermenting enzyme preparations

InactiveCN101254027AGood application effectIt has the characteristics of high temperature resistance of rebaking lineTobacco treatmentHydrolasesSucroseHalf-life

The invention relates to a novel production method of a tobacco-leaf fermentation enzymatic preparation, which aims at solving the technical problems how to improve tobacco-leaf fermentation quality and realize the activity protection of the tobacco-leaf fermentation enzymatic preparation in the tobacco-leaf spontaneous fermentation field. The enzymatic preparation is composed of glucose oxidase, chlorophyll oxidase, carotenoid oxidase, protease, and nicotine-degradation enzyme. Fresh tobacco leaves are processed through cell disruption, and processed through secondary fractional precipitation by (NH4)2SO4 to obtain crude enzyme liquid; enzyme molecules adopt Ca<2+> and Mg <2+> to act metal ion exchange to complete molecular modification; macromolecule combining modification is completed by adopting sucrose oligomer of 0.01 percent, so that the half-life of the enzymatic preparation can be prolonged, and the heat-resisting ability thereof can be increased markedly. Experimental results which are obtained by using the enzymatic preparation show that the nicotine is reduced 9.3 percent, total nitrogen is reduced 5.7 percent, protein is reduced 7.1 percent, smoke total particulate matter is reduced 8.4 percent, the quantity of the tar is reduced 5.1 percent, the nicotine content in smoke is reduced 28.0 percent, and carbon monoxide is reduced 1.6 percent. The enzymatic preparation is used in the secondary moistening process before threshing and re-drying of the tobacco leaves.

Owner:韩伟 +2

Screening methods for identifying ligands

InactiveUS6950757B2Microbiological testing/measurementFrom frozen solutionsScreening methodBioinformatics

This invention relates to crystallization based assays for identifying ligands that bind to a macromolecule.

Owner:EMERALD BIOSTRUCTURES

Identification of ligands for macromolecules

InactiveUS20070005258A1Reducing amount of data outputData visualisationBiological testingComputational chemistryMacromolecular binding

Methods and systems of analyzing positions and orientations of molecular fragments to generate macromolecular binding ligands, including analyzing the positions and orientations of molecular fragments in relation to other molecular fragments to bond the molecular fragments to form ligands.

Owner:SARNOFF CORP +1

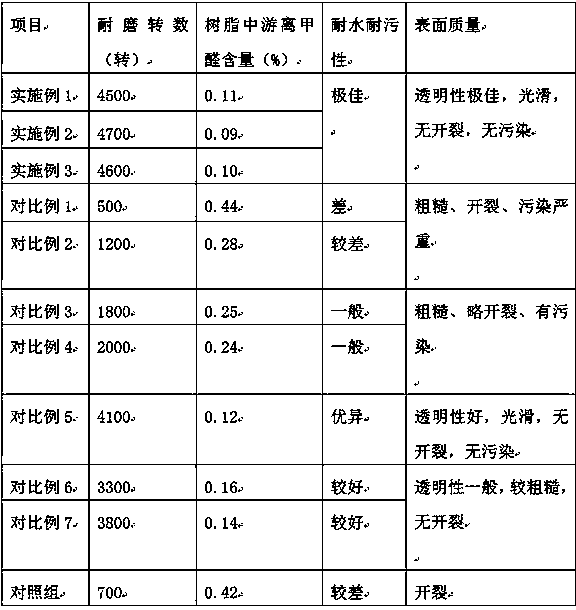

Method for improving abrasion resistance of impregnated paper laminated wood floor by using modified resin

ActiveCN109235830AImprove wear resistanceReduce processing costsPaper/cardboardInorganic compound additionWear resistantUltimate tensile strength

The invention relates to the technical field of novel functional materials, and discloses a method for improving abrasion resistance of an impregnated paper laminated wood floor by using a modified resin. By modifying a cured resin, a prepared wear resistance modifier is added to an impregnated resin, good dispersibility is achieved, macromolecules are combined to form a three-dimensional networkstructure, so that the wear resistance, strength and elasticity of an organic material are excellent, the modified impregnated resin has outstanding wear resistance, is processed into impregnated paper, and is paved on an artificial panel substrate to prepare the impregnated paper laminated wood floor, the problem that the performance of wear-resistant paper does not reach the standard is solved,the water and stain resistance is improved, the resin usage is reduced, free formaldehyde content reaches an European E0 standard, the problem of relying on the imported wear-resistant paper to improve the wear resistance of a wood board is effectively solved, the service life of the impregnated paper laminated wood floor is ensured, and the production process and cost of the impregnated paper laminated wood floor are fundamentally reduced.

Owner:阜南佳利工艺品股份有限公司

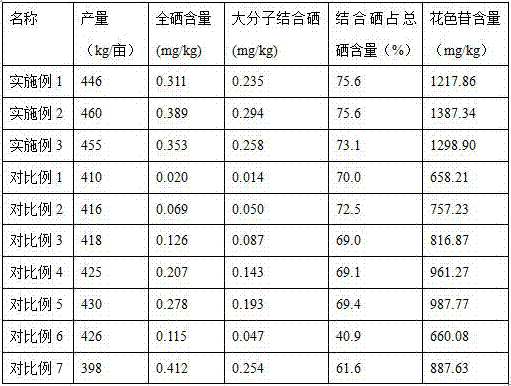

Planting method for increasing anthocyanin in black rice

ActiveCN107371531AIncrease anthocyanin contentIncrease contentFertilising methodsRice cultivationSeed treatmentSelenium

The invention provides a planting method for increasing anthocyanin in black rice. The planting method includes: using a selenate solution in a seed treatment period, a seedling period, a tillering period, an elongation period and a booting period. The black rice planted by the method is high in anthocyanin content; through rice stalk absorption, the rice is enabled to reach selenium-enriched level, content of all selenium and macromolecular combined selenium in the black rice is increased, and the black rice is high in nutrient content.

Owner:YANGXIAN YONGHUI AGRI IND DEVCO LTD

A hypoxic fluorescent imaging probe and its preparation method and application

ActiveCN111875597BSimple structureTo achieve the purpose of specific fluorescence imagingOrganic chemistryFluorescence/phosphorescenceNitroimidazoleHypoxic cell

The present invention provides a hypoxic fluorescent imaging probe and its preparation method and application. The hypoxic fluorescent imaging probe has a structure shown in formula I, named as: 1-(1-(2-nitroimidazole)-3 ‑[(4‑aminomethyl)azepine]‑2‑propanol)‑6‑(4‑nitrobenzo‑2‑oxa‑1,3‑oxadiazole)‑lysine, abbreviated PLN; the probe of the present invention can achieve specific fluorescence imaging of hypoxic cells through the nitroimidazole group of the probe to macromolecules in cells in different hypoxic environments, and the primary amino group in the molecule is beneficial Further modification of the molecule.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

A planting method for improving anthocyanins in black rice

ActiveCN107371531BIncrease anthocyanin contentIncrease contentFertilising methodsRice cultivationSeed treatmentOryza sativa

The invention provides a planting method for increasing anthocyanin in black rice. The planting method includes: using a selenate solution in a seed treatment period, a seedling period, a tillering period, an elongation period and a booting period. The black rice planted by the method is high in anthocyanin content; through rice stalk absorption, the rice is enabled to reach selenium-enriched level, content of all selenium and macromolecular combined selenium in the black rice is increased, and the black rice is high in nutrient content.

Owner:YANGXIAN YONGHUI AGRI IND DEVCO LTD

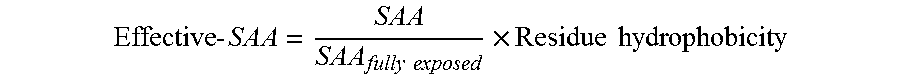

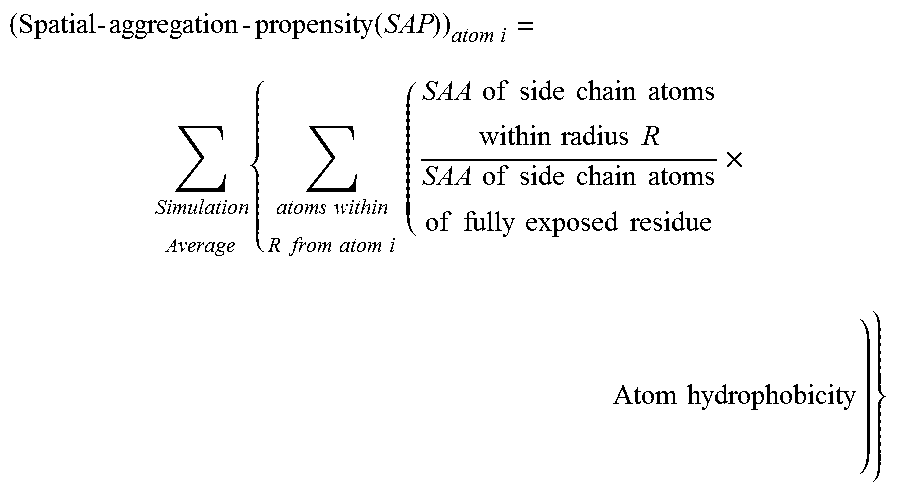

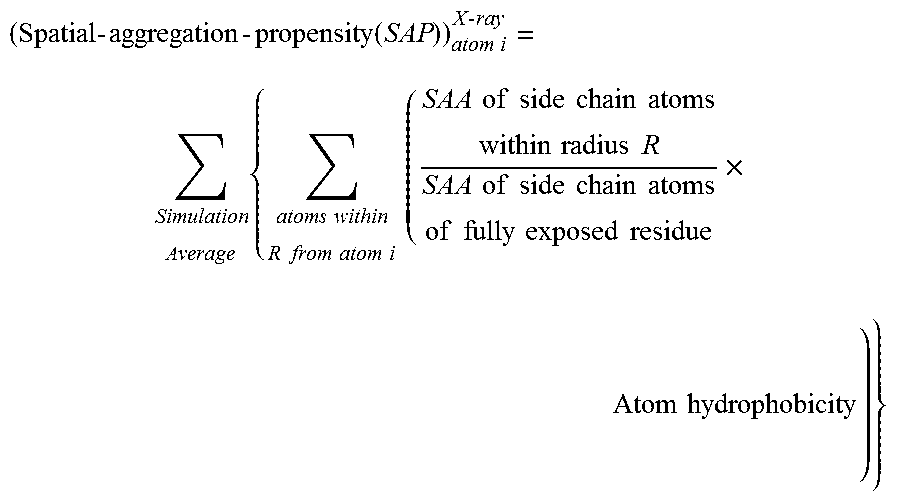

Methods to identify macromolecule binding and aggregation prone regions in proteins and uses therefor

ActiveUS20160364521A1Improve stabilityReduction tendencyPeptide/protein ingredientsMolecular designBiologyAvidity

The present invention provides methods and computational tools based, at least in part, on computer simulations that identify macromolecule binding regions and aggregation prone regions of a protein. Substitutions may then be made in these aggregation prone regions to engineer proteins with enhanced stability and / or a reduced propensity for aggregation. Similarly, substitutions may then be made in these macromolecule binding regions to engineer proteins with altered binding affinity for the macromolecule.

Owner:NOVARTIS AG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com