Preparation method and related products of SrVO3 nanofibers

A nanofiber and soluble technology, applied in the field of nanofibrous webs, can solve the problems of limited application and achieve the effect of low cost and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

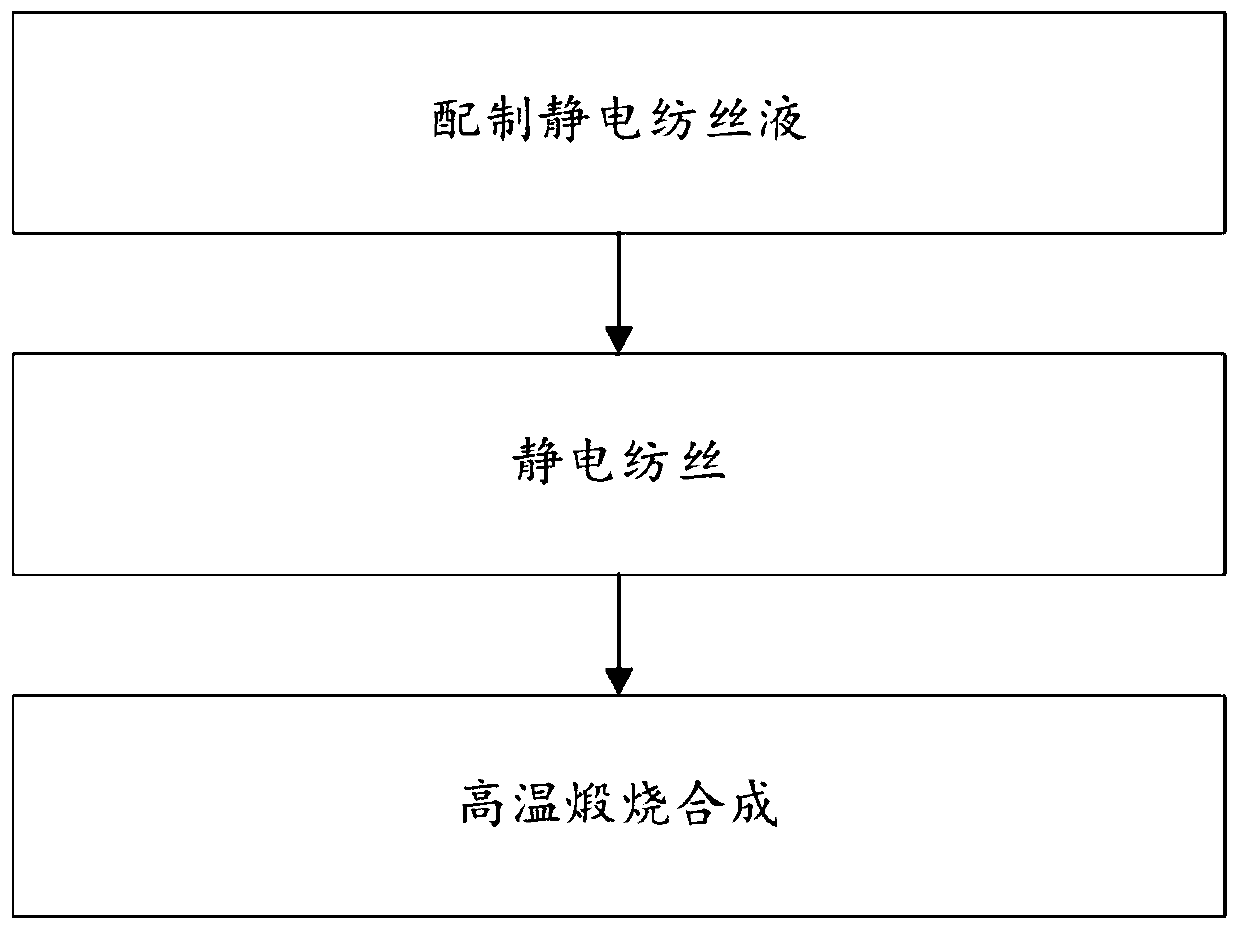

[0052] according to figure 1 As shown in the flowchart, first, weigh 2.11g of strontium nitrate and 1.17g of ammonium metavanadate and dissolve them in 5.22g of heated deionized water, stir until fully dissolved, then add 1.5g of polyvinylpyrrolidone, and stir until the solution is clear to obtain static electricity. spinning solution. Then, the above electrospinning solution was transferred to an electrospinning device. Further, the parameters of electrospinning are set as follows: electrospinning voltage 12kV, spinning rate 2mL / h, spinning distance 15cm, ambient humidity 50%, ambient temperature 25°C, and using a receiving device, such as electrospinning The substrate of the device receives the precursor nanofibers. Finally, the collected precursor nanofibers were pre-oxidized and calcined at 500°C in the air, the heating rate was set at 5°C / min, and the holding time was 2h; then the SrO / V 2 o 5 The oxide nanofibers were transferred to a hydrogen tube furnace, the heatin...

Embodiment 2

[0058] according to figure 1 As shown in the flowchart, first, weigh 2.11g of strontium nitrate and 1.17g of ammonium metavanadate and dissolve them in 5.22g of heated deionized water, stir until fully dissolved, then add 1.5g of polyvinylpyrrolidone, and stir until the solution is clear to obtain static electricity. spinning solution. Then, the above-mentioned electrospinning solution was transferred to the electrospinning equipment, and the parameters of the electrospinning were set as: electrospinning voltage 12kV, spinning rate 2mL / h, spinning distance 15cm, ambient humidity 50%, ambient The temperature is 25 °C, and the precursor nanofibers are received using a receiving device, such as a substrate of an electrospinning device. Finally, the collected precursor nanofibers were pre-oxidized and calcined at 500°C in the air, the heating rate was set at 5°C / min, and the holding time was 2h; then the pre-oxidized and calcined fibers in the air were transferred to the hydrogen...

Embodiment 3

[0060] according to figure 1 As shown in the flowchart, first, weigh 2.11g of strontium nitrate and 1.17g of ammonium metavanadate and dissolve them in 5.22g of heated deionized water, stir until fully dissolved, then add 1.5g of polyvinylpyrrolidone, and stir until the solution is clear to obtain static electricity. spinning solution. Then, the above-mentioned electrospinning solution was transferred to the electrospinning equipment, and the parameters of the electrospinning were set as: electrospinning voltage 12kV, spinning rate 2mL / h, spinning distance 15cm, ambient humidity 50%, ambient The temperature is 25 °C, and the precursor nanofibers are received using a receiving device, such as a substrate of an electrospinning device. Finally, the collected precursor nanofibers were pre-oxidized and calcined at 500°C in the air, the heating rate was set at 5°C / min, and the holding time was 2h; then the pre-oxidized and calcined fibers in the air were transferred to the hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com