Novel water-based graphene polyurethane coating and preparation method thereof

A water-based graphene and polyurethane coating technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as easy agglomeration, material performance degradation, and graphene's excellent performance cannot be exerted, and achieve excellent mechanical properties and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

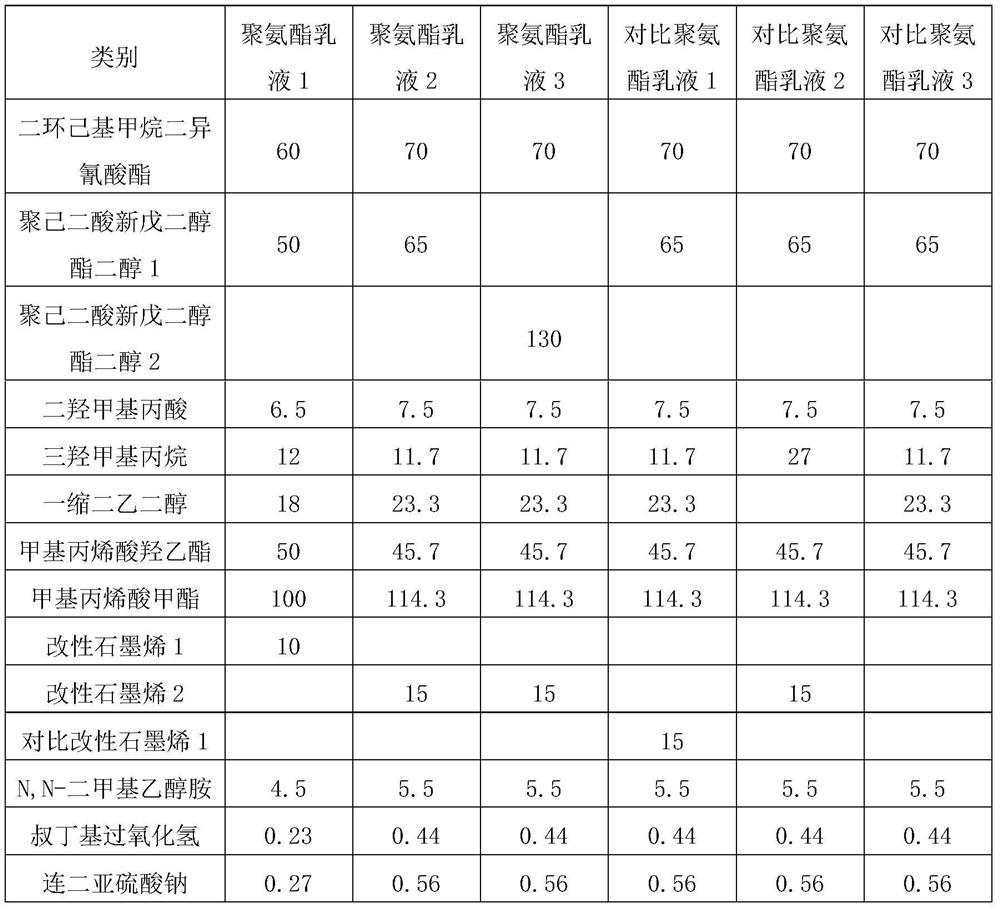

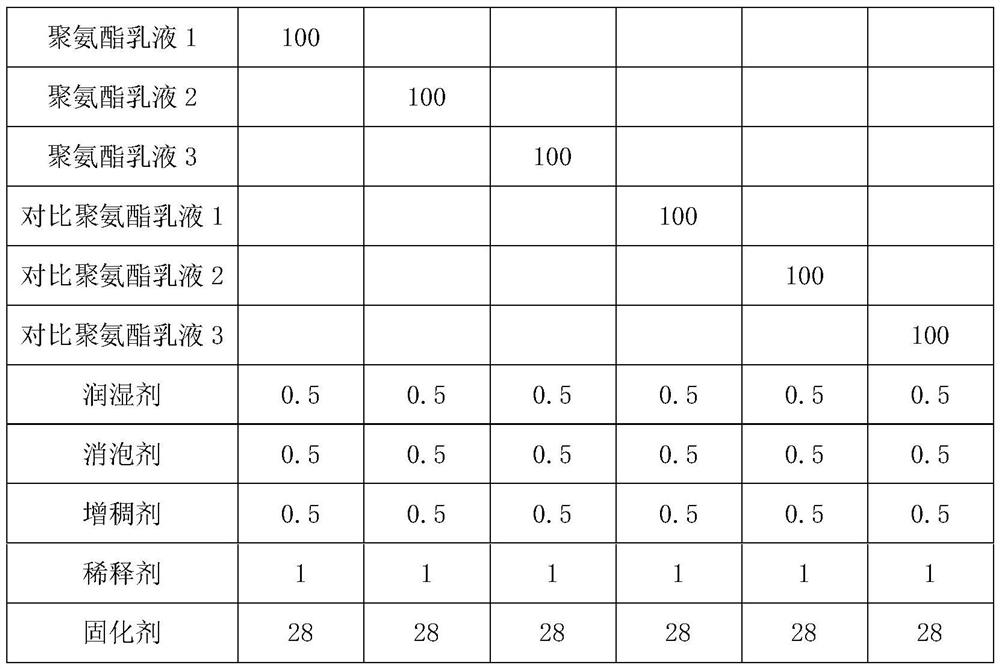

[0044] The present invention will be further described below in conjunction with specific examples. Unless otherwise specified, the reagents, methods and equipment used in the present invention are conventional reagents, methods and equipment in the technical field.

[0045] The raw materials used in embodiment and comparative example are as follows:

[0046] Dicyclohexylmethane diisocyanate, produced by BASF;

[0047] Polyneopentyl glycol adipate diol 1, number average molecular weight 1000, produced by BASF;

[0048] Polyneopentyl glycol adipate diol 2, number average molecular weight 2000, produced by BASF;

[0049] Graphene oxide, grade S28018, produced by Shanghai Yuanye Biotechnology Co., Ltd.;

[0050] Wetting agent, grade BD109, produced by Dow Chemical;

[0051] Defoamer, TEGO825, produced by BYK;

[0052] Thickener, brand U604, produced by Wanhua Chemical Company;

[0053] thinner, water;

[0054] Curing agent, grade aquolin278, produced by Wanhua Chemical Compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com