Producing method of novel tobacco fermenting enzyme preparations

A technology of enzyme preparation and compound enzyme preparation, which is applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems that the requirements for mass production of cigarette enterprises have not been described, and achieve improved application effects, convenient application, and shortened natural fermentation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

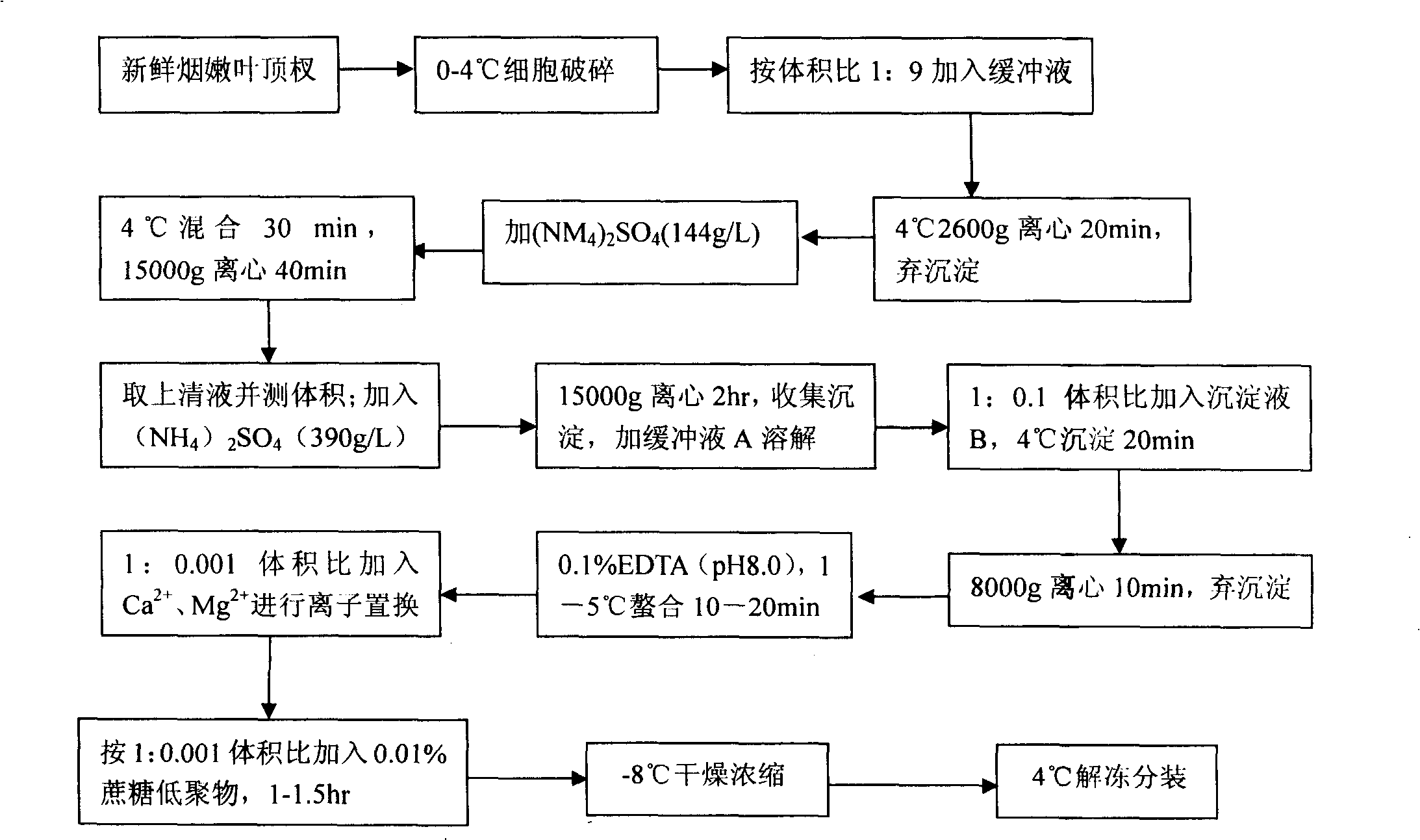

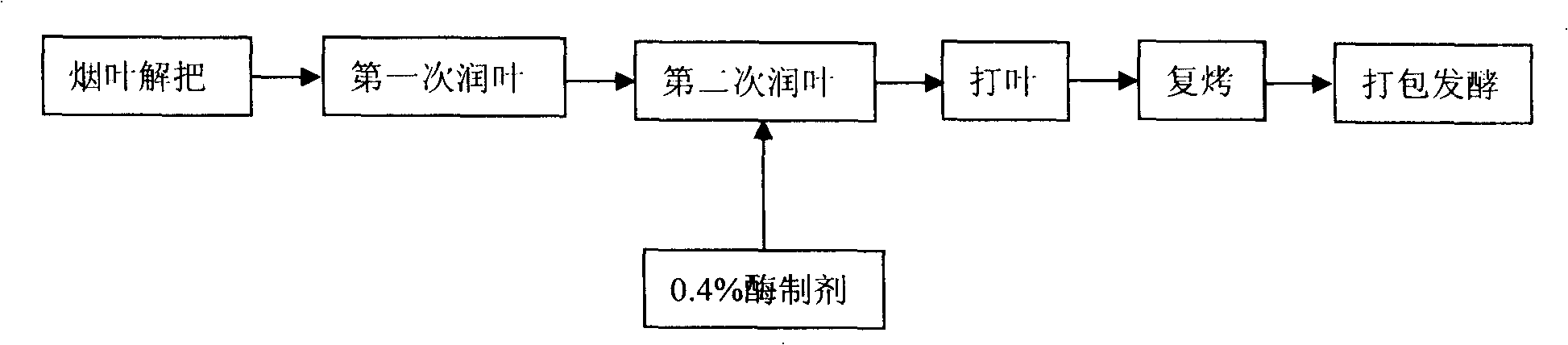

Method used

Image

Examples

Embodiment approach

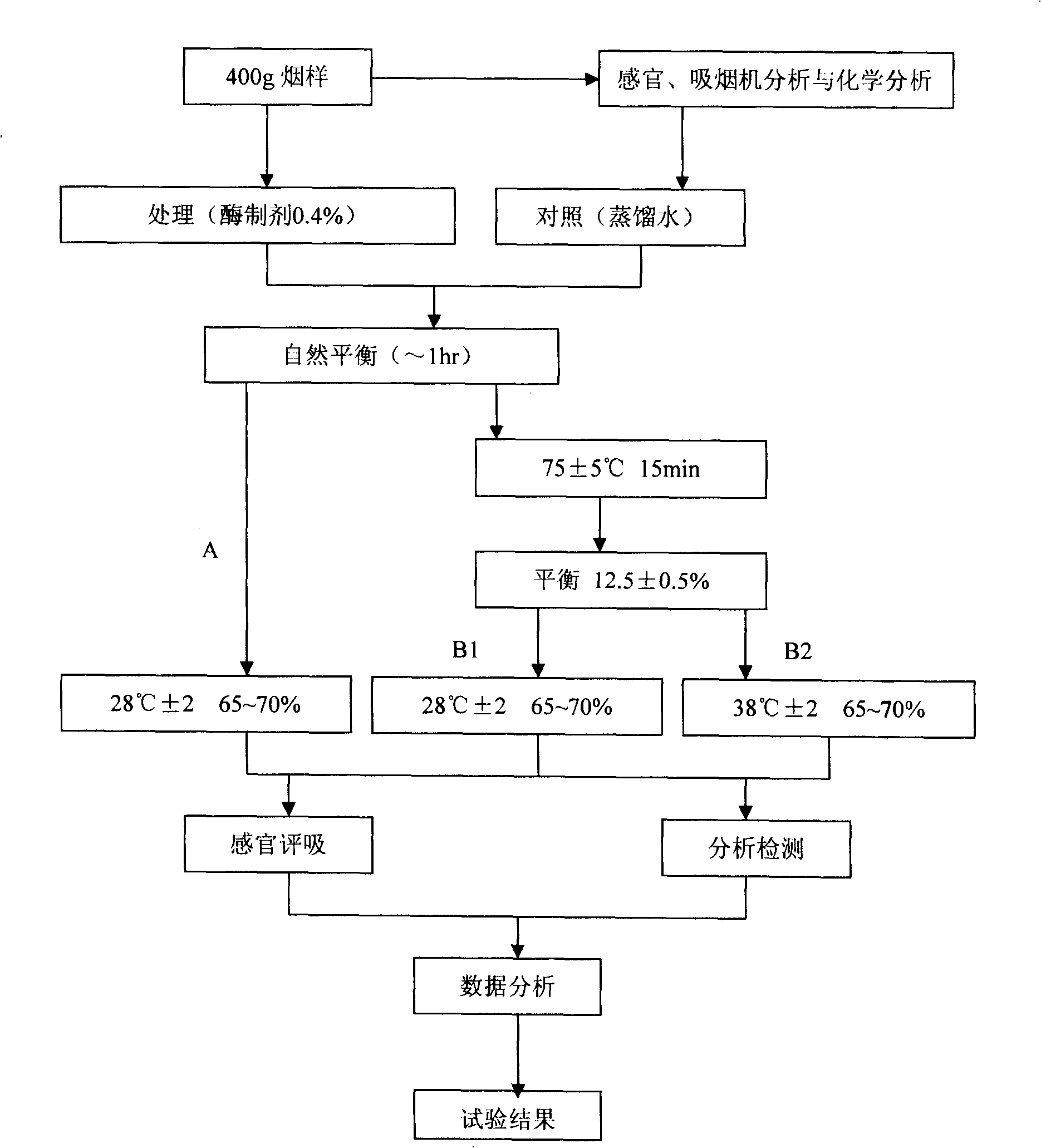

[0046] Implementation (see Figure 3)

[0047] 1. Select B2F, a representative tobacco leaf from the upper part of Yun 85 in the Hongta area of Yuxi;

[0048] 2. Prepare a 0.4% solution according to the instructions of the enzyme preparation, spray the B2F smoke sample evenly at room temperature, and alcoholize at a temperature of 28°C and a relative humidity of 65%; (A)

[0049] 3. Simulate the re-baking process conditions (75±5°C), process the smoke samples according to the method in 1, store them at 28°C (B1) and 38°C (B2) respectively, and carry out alcoholization under the condition of relative humidity of 65%;

[0050] 4. Conduct professional smoking evaluation, smoking machine analysis and routine chemical analysis on (A), (B1) and (B2) smoke samples after 60 days;

[0051] 5. Use MATLAB statistical analysis software for data analysis.

[0052] The results of sensory evaluation showed that (A) method significantly improved the quality of tobacco leaves, showing that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com