Method for improving abrasion resistance of impregnated paper laminated wood floor by using modified resin

A technology of modified resin and impregnated paper, which is applied in the field of new functional materials, can solve the problems of non-standard performance of wear-resistant paper, achieve the effects of improving wear resistance, highlighting wear resistance, and overcoming performance substandard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

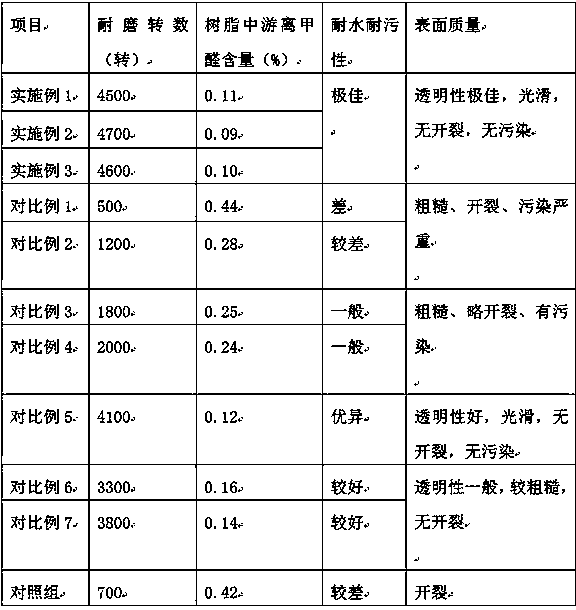

Examples

Embodiment 1

[0018] A method for improving the abrasion resistance of impregnated paper laminated wood floors by using modified resin, which is made of the following components in parts by weight: 65 parts of urea, 45 parts of formaldehyde, 6.5 parts of melamine, 5.0 parts of polyethylene glycol, hydrogen 4.0 parts of sodium solution, 3.0 parts of formic acid solution, 0.3 part of sodium hexametaphosphate, 0.18 part of modifying agent; the preparation method of described modifying agent comprises the following steps:

[0019] (1) Weigh 7.8 grams of zinc sulfate and 6.4 grams of sodium carbonate powder, place them in a crucible and grind for 30 minutes, then mix the two, and add 0.8 grams of bis-[3-(triethoxysilyl)propyl]- Disulfides were ground together for 10 minutes, placed in a far-infrared drying oven, irradiated at 107°C for 1.2 hours and taken out to obtain modified zinc carbonate powder, which was placed in a constant temperature drying oven at 60°C for subsequent use;

[0020] (2) ...

Embodiment 2

[0028] A method for improving the wear resistance of impregnated paper laminated wooden floors by using modified resin, which is made of the following components in parts by weight: 66 parts of urea, 48 parts of formaldehyde, 7.0 parts of melamine, 5.5 parts of polyethylene glycol, and 4.2 parts of sodium solution, 3.2 parts of formic acid solution, 0.35 part of sodium hexametaphosphate, 0.19 part of modifying agent; the preparation method of described modifying agent comprises the following steps:

[0029] (1) Weigh 7.9 grams of zinc sulfate and 6.5 grams of sodium carbonate powder, place them in a crucible and grind for 35 minutes, then mix the two, and add 0.85 grams of bis-[3-(triethoxysilyl)propyl]- Disulfides were ground together for 12 minutes, placed in a far-infrared drying oven, irradiated at 108°C for 1.3 hours and taken out to obtain modified zinc carbonate powder, which was placed in a constant temperature drying oven at 62°C for subsequent use;

[0030] (2) Weigh 1...

Embodiment 3

[0038] A method for improving the wear resistance of impregnated paper laminated wooden floors by using modified resin, which is made of the following components in parts by weight: 68 parts of urea, 50 parts of formaldehyde, 7.5 parts of melamine, 6.0 parts of polyethylene glycol, hydrogen 4.5 parts of sodium solution, 3.5 parts of formic acid solution, 0.4 part of sodium hexametaphosphate, 0.20 part of modifying agent; the preparation method of described modifying agent comprises the following steps:

[0039] (1) Weigh 8.0 grams of zinc sulfate and 6.6 grams of sodium carbonate powder, place them in a crucible and grind them for 40 minutes, then mix the two, and add 0.9 grams of bis-[3-(triethoxysilyl)propyl]- Disulfides were ground together for 15 minutes, placed in a far-infrared drying oven, irradiated at 110°C for 1.5 hours and taken out to obtain modified zinc carbonate powder, which was placed in a constant temperature drying oven at 65°C for subsequent use;

[0040] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com