Permanen magnet synchronous motor

A permanent magnet synchronous motor technology, applied in the field of motors, can solve the problems that the motor cannot work normally, the torque characteristics of the motor are deteriorated, and the starting of the motor is affected. Effect of small torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

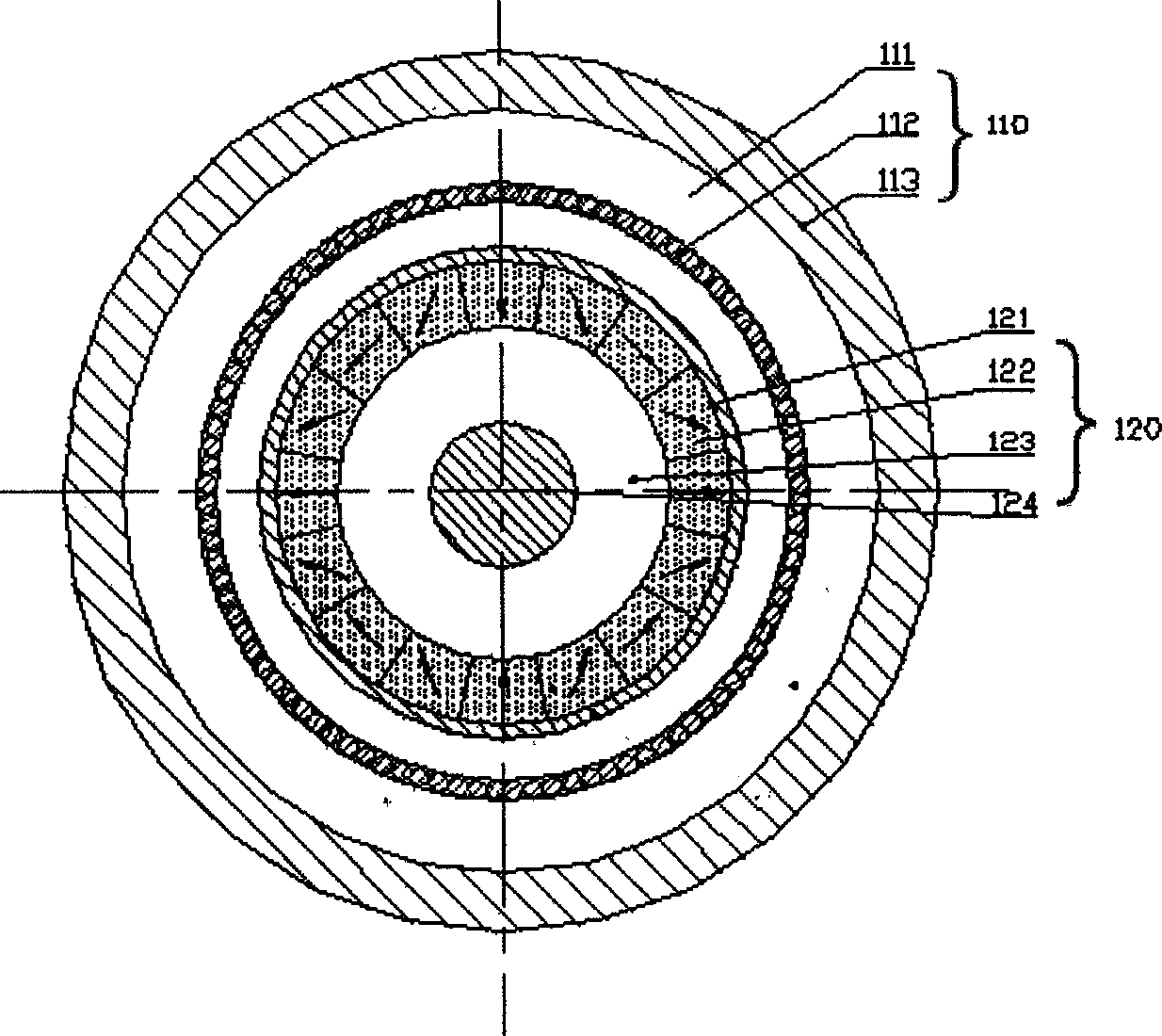

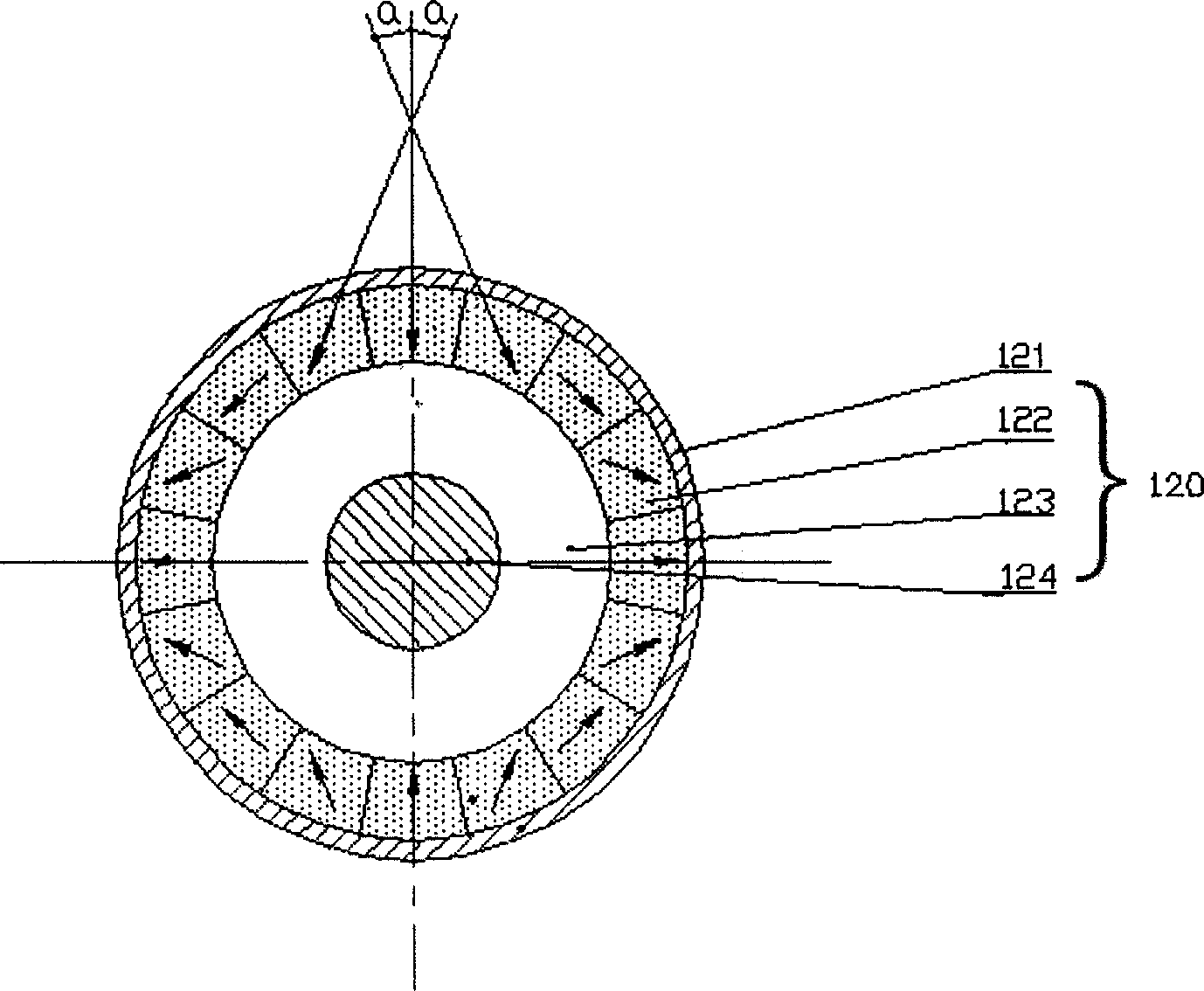

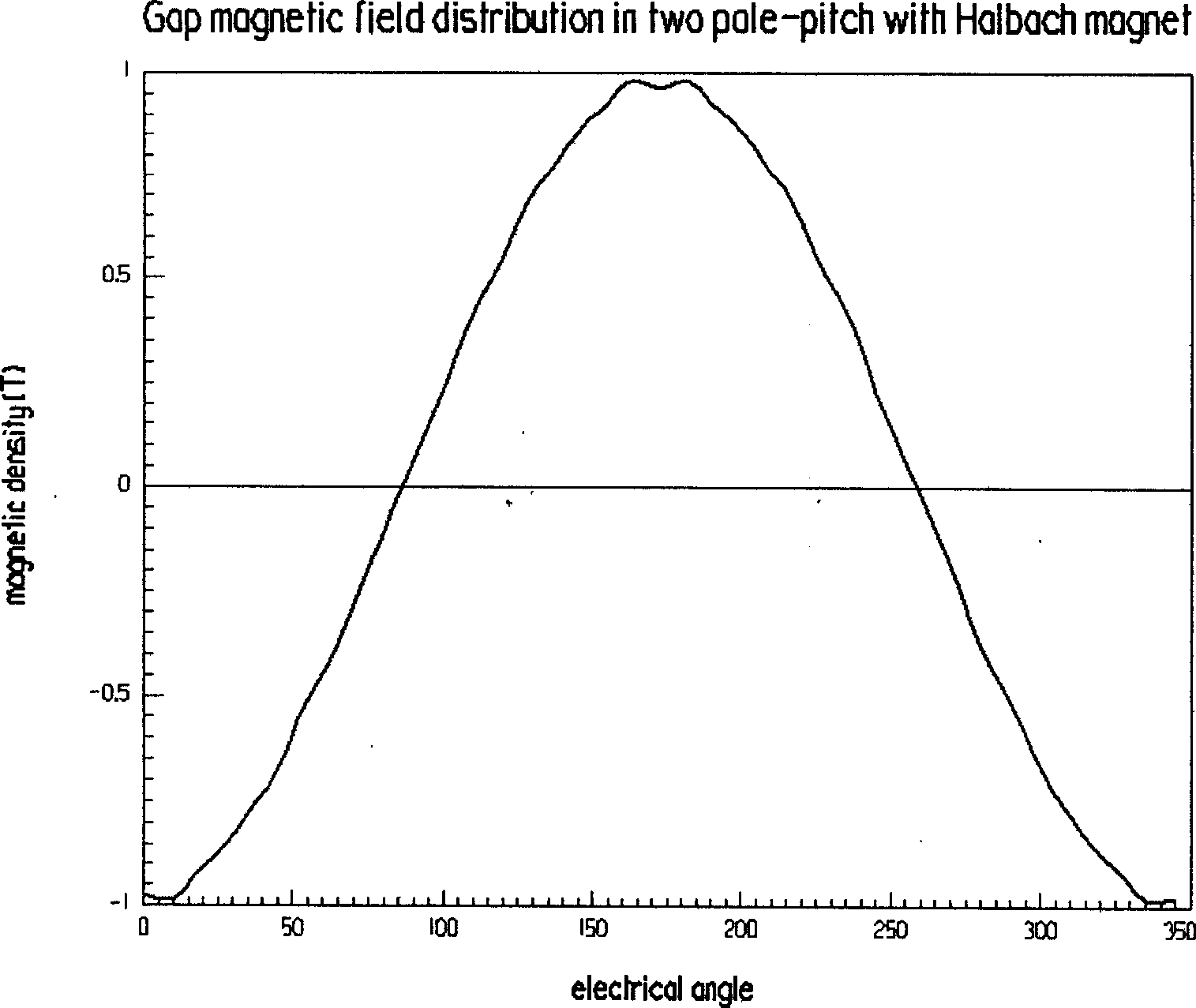

[0029] Such as figure 1 As shown, the specific embodiment of the external magnetic field (or internal magnetic pole) motor of the present invention is composed of a stator 110, a rotor 120 and the like. The stator 110 includes a stator slotless iron core 111 , an armature winding 112 and a stator frame 113 . The rotor 120 includes a magnetic pole fixing sleeve 121 , a permanent magnetic pole 122 , a rotor yoke 123 and a rotating shaft 124 . The cogged core 111 in the stator 110 is made of silicon steel sheets and is fixed with the machine base 113; each winding element of the three-phase or multi-phase armature winding 112 is formed by winding, and then bonded or mechanically fixed on the surface of the stator slotless iron core 111 to form an air gap winding 112 . Each magnet block of the permanent magnet pole 122 is bonded to the rotor yo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com