Winding carved heat equalizing plate with metal net micro structure and its producing method

A technology of vapor chamber and metal mesh, which is applied in the cooling of instruments, parts of instruments, cooling/ventilation/heating transformation, etc., which can solve the problems of thermal deformation of shells, high product defect rate and manufacturing costs, and shells that are easy to be heated Deformation and other problems, to achieve the effect of low manufacturing cost, easy to form, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

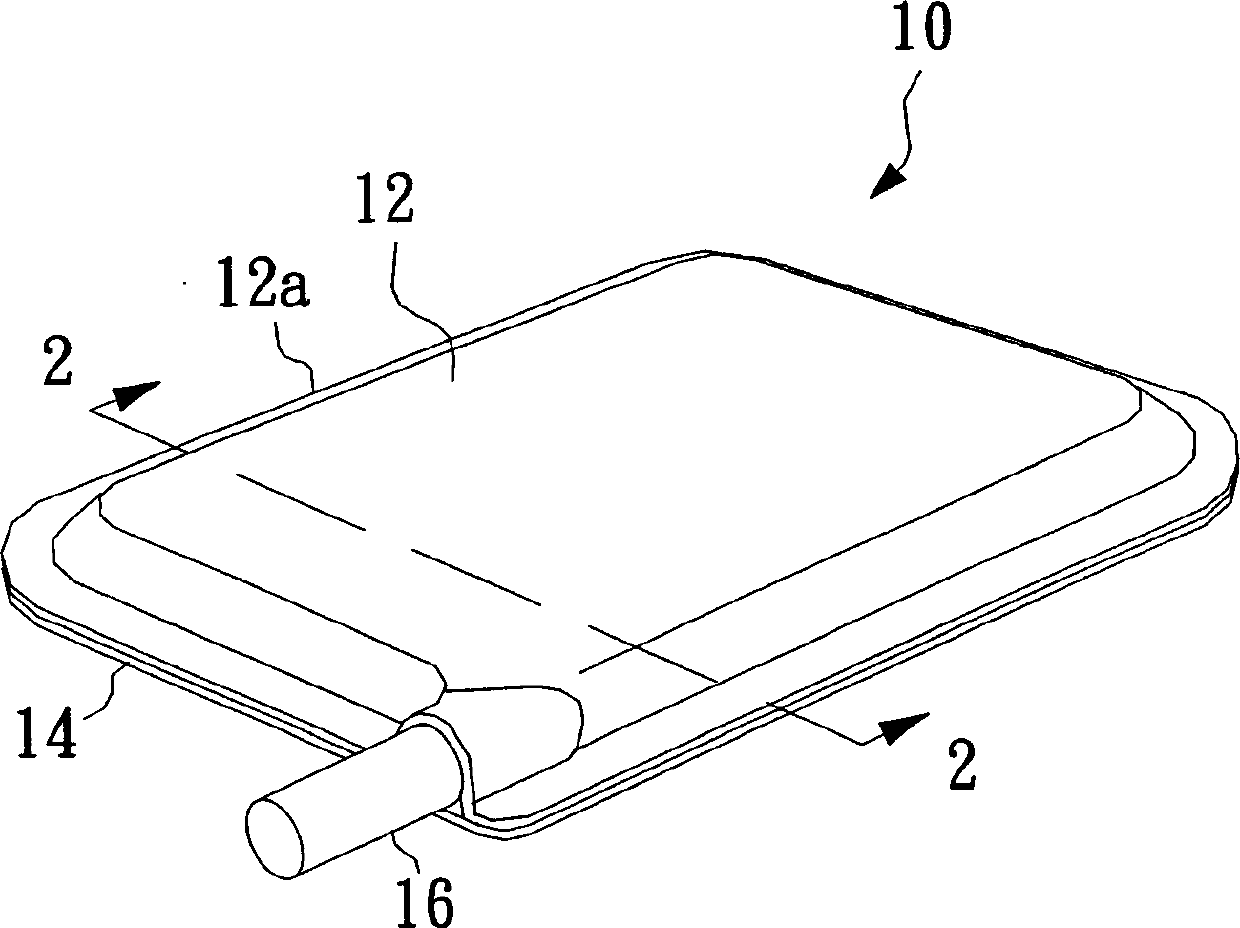

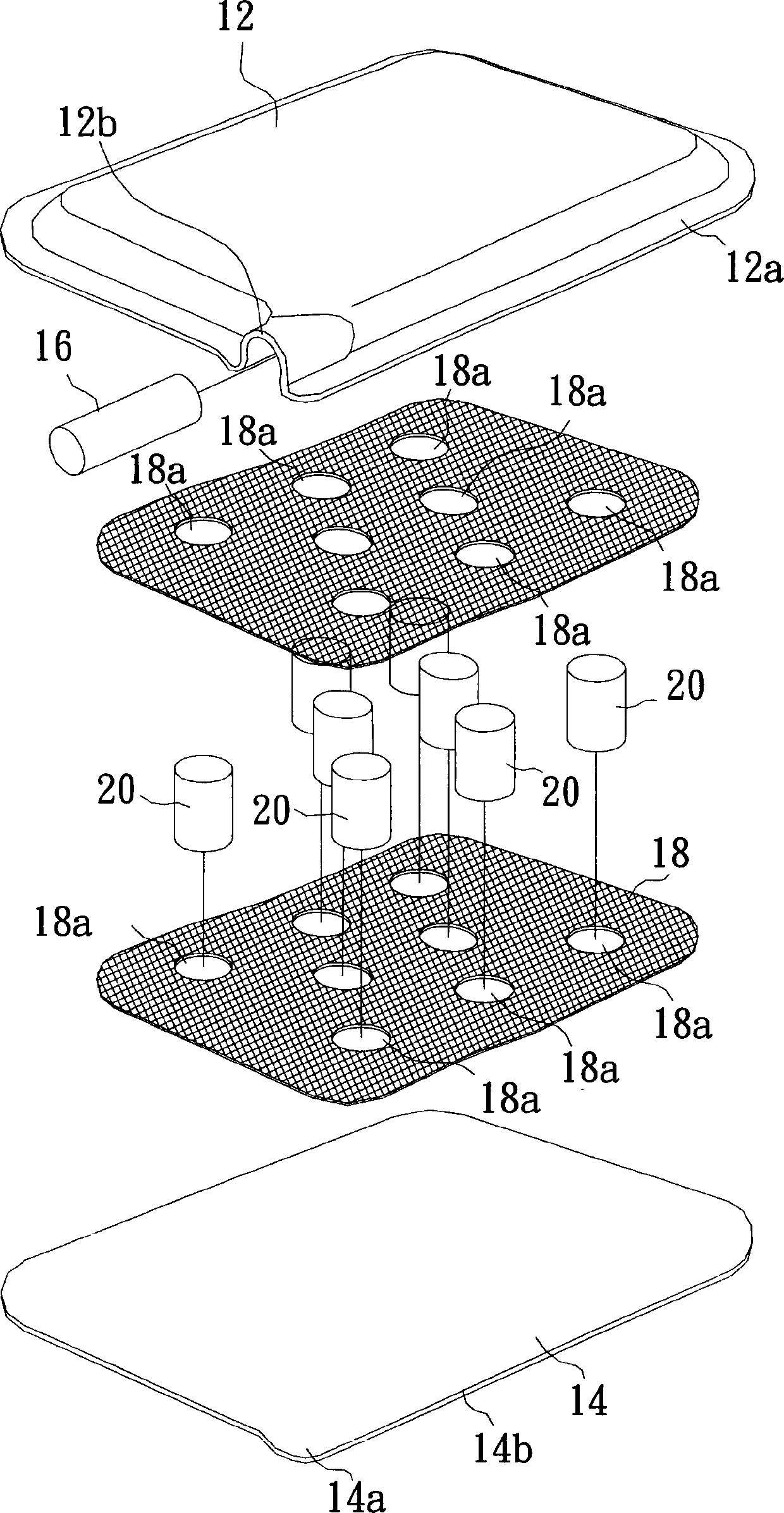

[0037] Fig. 1 shows the appearance of a soaking plate 10 according to the present invention. The soaking plate 10 includes an upper cover 12, a lower cover 14 and a filling tube 16. Their material is usually copper, but other metals with good heat dissipation properties (such as aluminum as the material) can also be used.

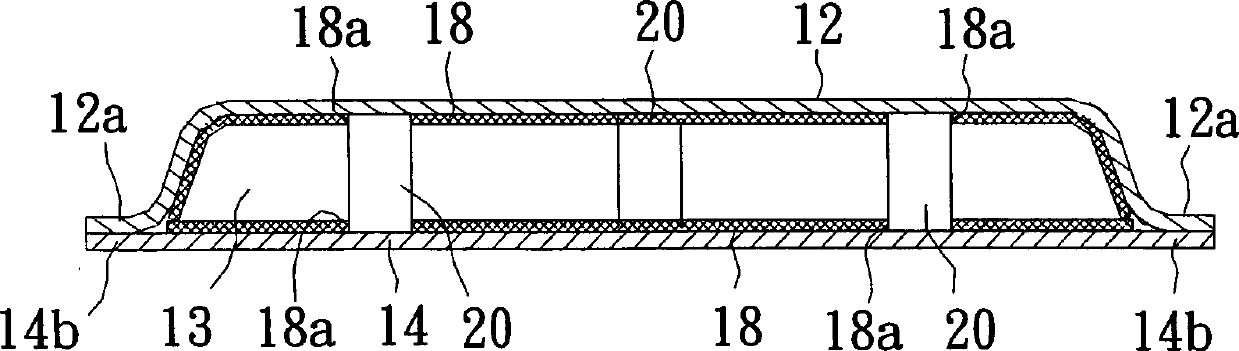

[0038] 2 and 3 show the first embodiment of the structure of the heat equalizing plate 10 of the present invention. The upper cover 12 has an edge 12a. The part inside the edge 12a is slightly convex. The edge 12a and the edge 14b of the lower cover 14 are diffusely joined here to form a hollow shell, forming a vacuum-tight chamber 13 for supply Fill it with an appropriate amount of working fluid (such as pure water, not shown in the figure). One end of the filling tube 16 used to inject the working fluid into the chamber 13 is in communication with the chamber 13 and the other end is closed.

[0039] According to one feature of the present invention, the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com