Multiple synchronization module for gearbox and gearbox

A technology of synchronizing module and synchronizer, which is applied to clutches, mechanical drive clutches, gear transmissions, etc., can solve the problems of increased unlocking force and cost, and achieve the effect of reducing manufacturing costs and simplifying manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

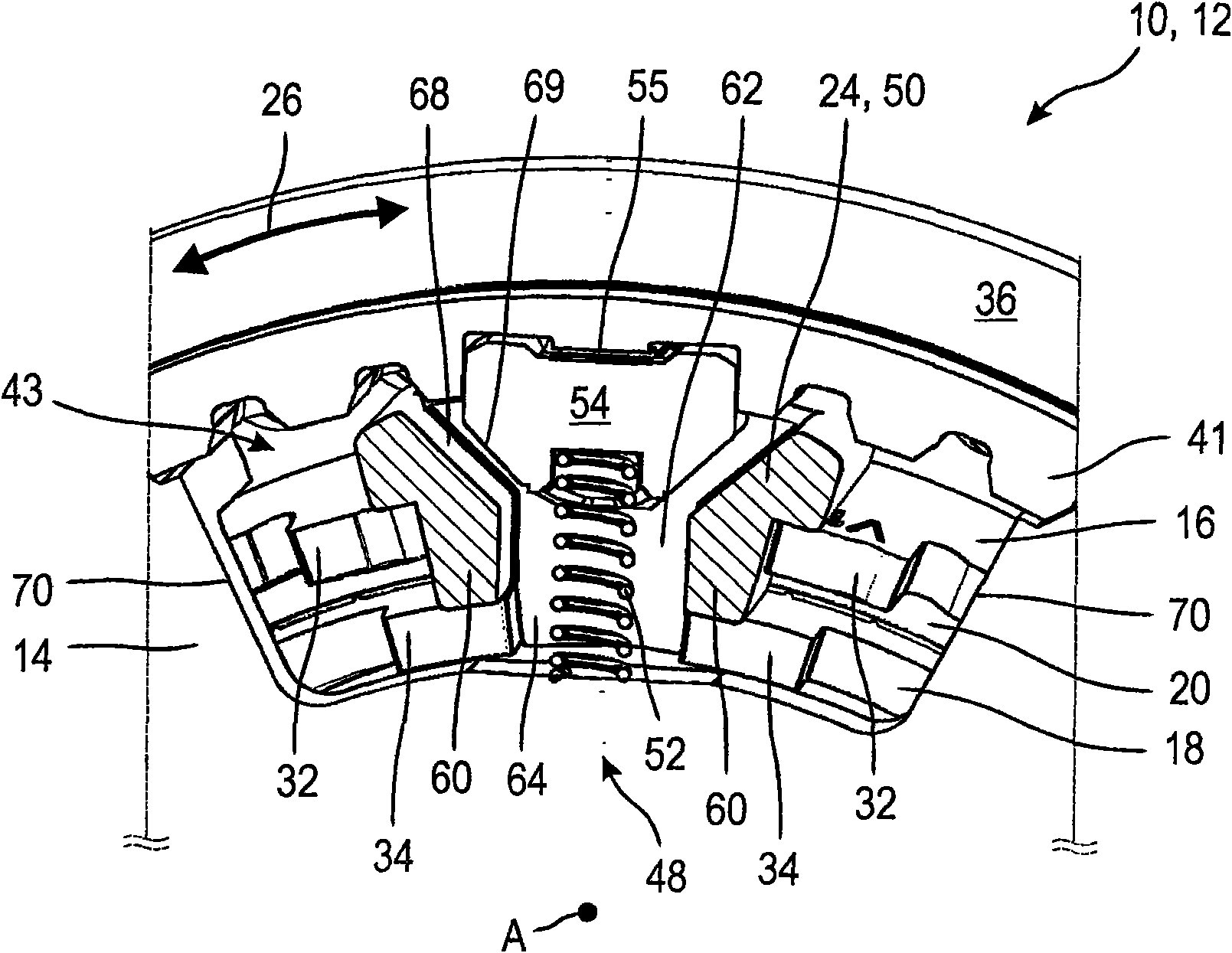

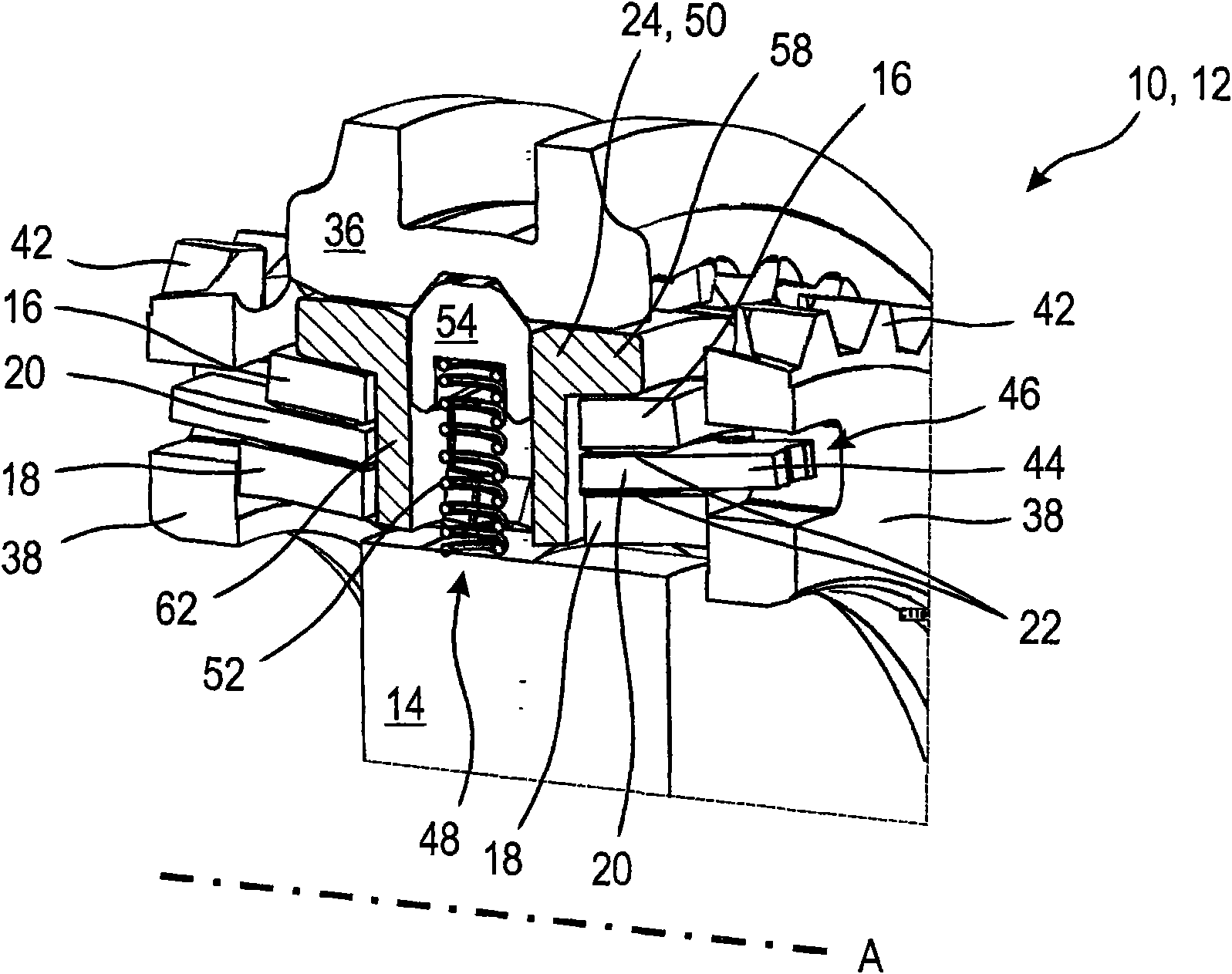

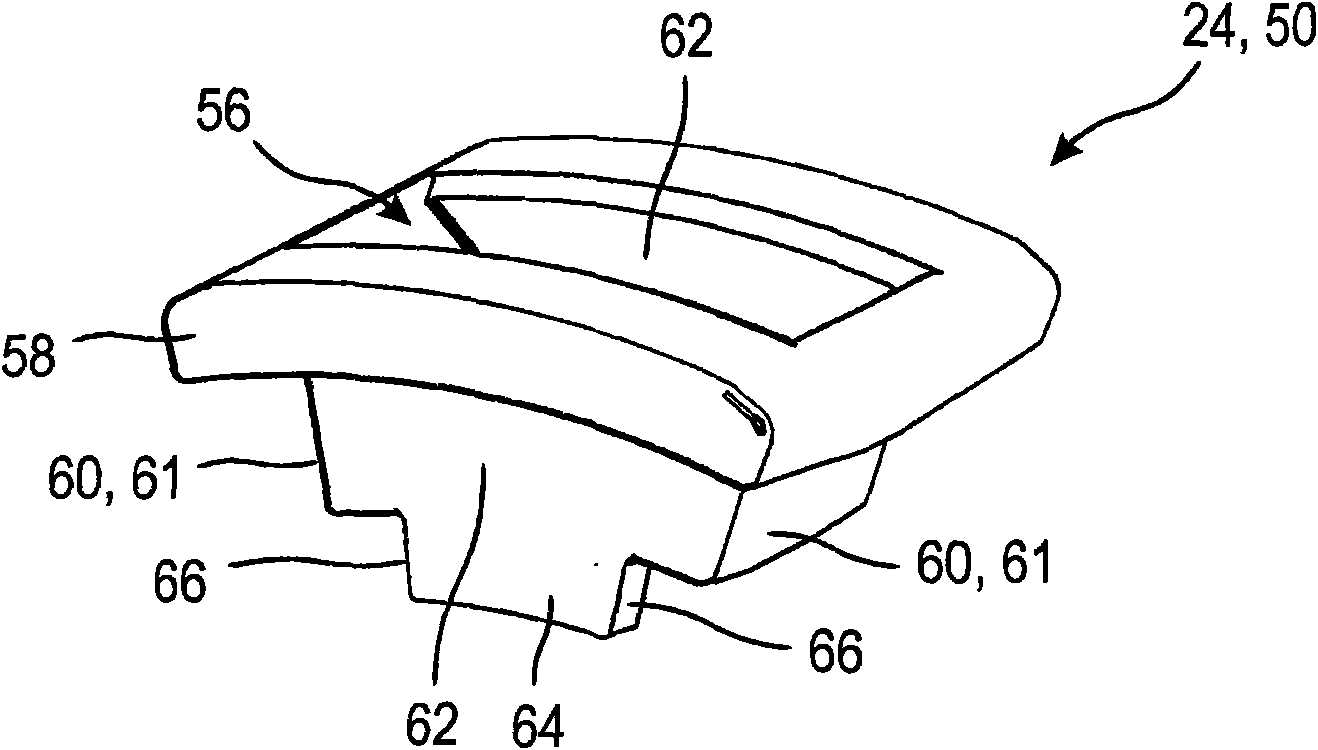

[0024] figure 1 and figure 2 Shown is a detailed view in cross section and a detailed view in longitudinal section of a multi-stage synchronizing module 10 of a transmission 12 with a synchronizer 14 rotatable about a drive axis A, a rotatable about a drive axis A A first-stage conical ring 16 , a second-stage conical ring 18 rotatable around the transmission axis A, and a third-stage conical ring 20 rotatable around the transmission axis A. The third-stage conical ring is arranged radially between the first-stage conical ring 16 and the second-stage conical ring 18 and can establish frictional connection with the first-stage conical ring 16 and the second-stage conical ring 18 . The conical rings 16 , 18 , 20 each have a friction surface 22 for establishing a frictional connection. These friction surfaces can at least partially be equipped with a special friction lining.

[0025] The multistage synchronization module 10 has a separate connection element 24 for this purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com