Construction method for pretensioned prestressing concrete simply supported T-beam

A construction method and concrete technology, applied in bridges, construction materials processing, construction, etc., can solve the problems of large tonnage, no research records, large span, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described in detail below in conjunction with specific embodiments.

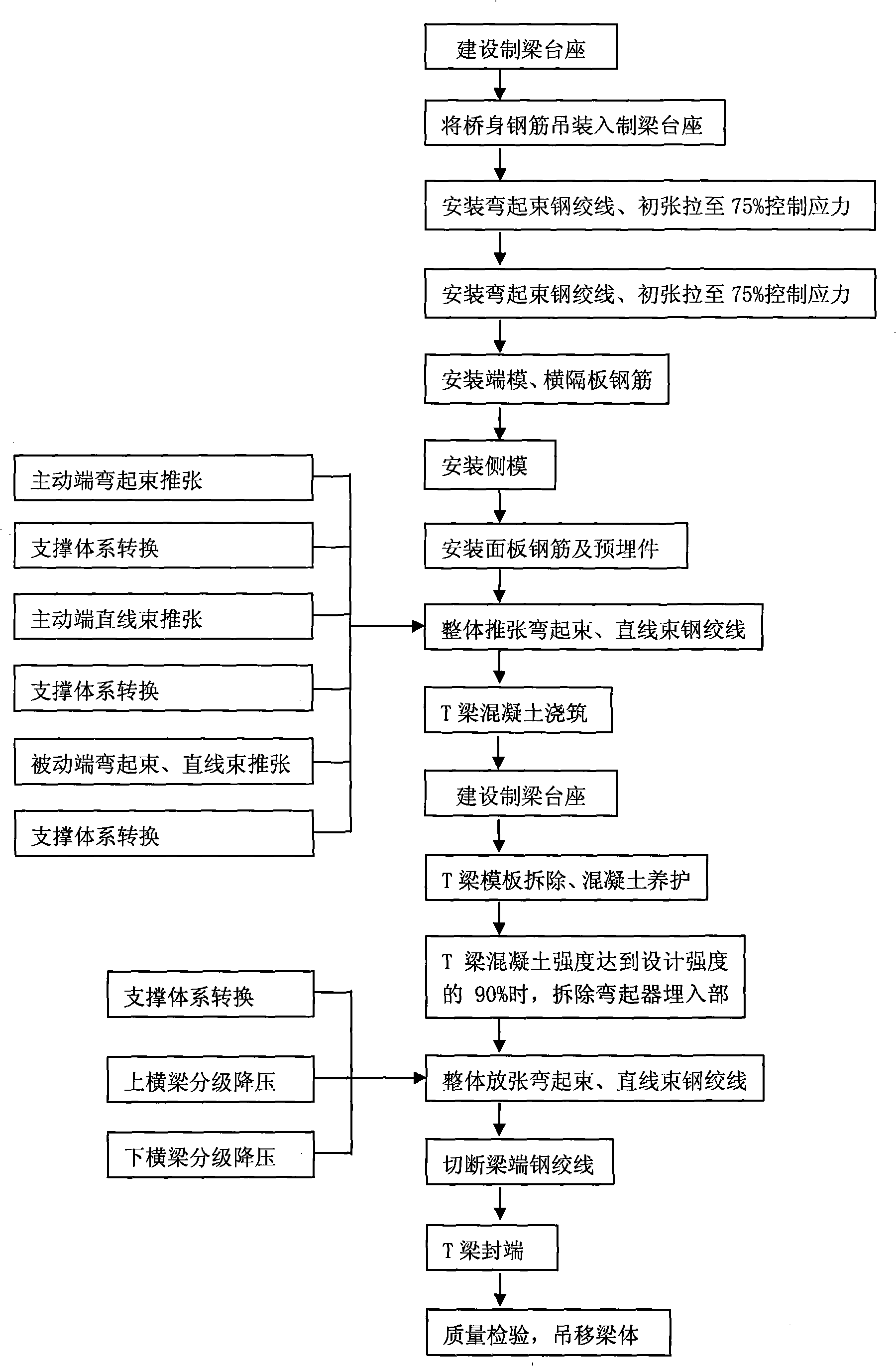

[0078] The construction method of 50m / 1200t level pretensioned prestressed concrete simply supported T-beam, its process is as follows figure 1 As shown, its main processes include:

[0079] a. Construction beam pedestal,

[0080] b. Hoist the steel bars of the bridge body into the girder pedestal,

[0081] c. Install PVC pipes, install and initially tension steel strands,

[0082] d. Install the end formwork and diaphragm reinforcement,

[0083] e. Install side forms,

[0084] f. Install panel reinforcement and embedded parts,

[0085] g. The whole pushes and stretches the bent and straight bundled steel strands,

[0086] h. T beam concrete pouring,

[0087]i.T beam formwork demolition, concrete curing,

[0088] j. When the concrete strength of the T-beam reaches 90% of the design strength, after the embedded part of the bender is removed, the bent bundle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com