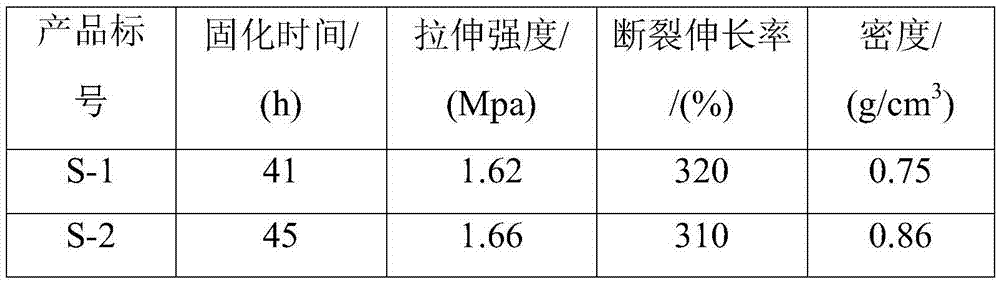

Low-density deketoxime type silicone sealant and preparation method thereof

A technology of silicone sealant and deketoxime, which is used in adhesives, adhesive additives, non-polymer adhesive additives, etc. Brittleness and other problems, to achieve the effect of reducing the density of the sealant, good foaming performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A low-density deketoxime type silicone sealant, consisting of the following components in parts by weight:

[0030] α,ω-Dihydroxypolydimethylsiloxane

100g

25g

Thermally expandable microcapsules F-48

0.3g

Vinyl tributylketoxime silane (crosslinking agent)

2g

Methyltributylketoximosilane (crosslinking agent)

15g

Modified CaCO 3 (reinforcing filler)

80g

γ-aminopropyltriethoxysilane (coupling agent)

2g

Dibutyltin dilaurate (catalyst)

0.2g

[0031] The preparation method of the low-density deketoxime type silicone sealant is as follows:

[0032] A. Mix 100g of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 30mpa·s, 25g of simethicone oil with a viscosity of 400pa·s, 0.3g of thermally expandable microcapsules F-48, and 80g of modified CaCO 3 After mixing, put it into a planetary stirring tank for stirring, control the temperature at 120°C, and mix for 3 hours ...

Embodiment 2

[0036] A low-density deketoxime type silicone sealant, which consists of the following components:

[0037] a,ω-Dihydroxypolydimethylsiloxane

100g

10g

Thermally expandable microcapsules F-50

0.5g

Methyltributylketoximosilane (crosslinking agent)

12g

Modified CaCO 3 (reinforcing filler)

100g

γ-(2,3-Epoxypropyl)propyltrimethoxysilane (coupling agent)

1.6g

Dibutyltin dilaurate (catalyst)

0.3g

[0038]The preparation method of the low-density deketoxime type silicone sealant is as follows:

[0039] A. Mix 100g of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 40mpa·s, 10g of simethicone oil with a viscosity of 500pa·s, 0.5g of thermally expandable microcapsules F-50, and 100g of modified CaCO 3 After mixing, put it into a planetary stirring tank for stirring, control the temperature at 130°C, and mix for 3 hours under the condition of vacuum degree -0.098MPa, and then pass N...

Embodiment 3

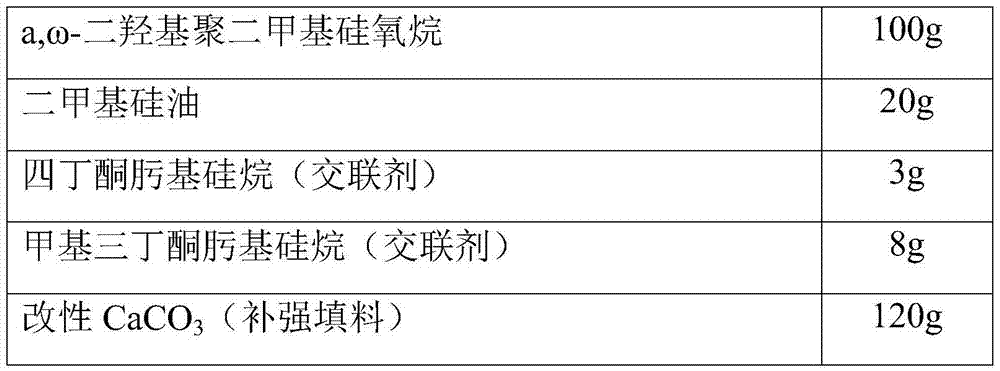

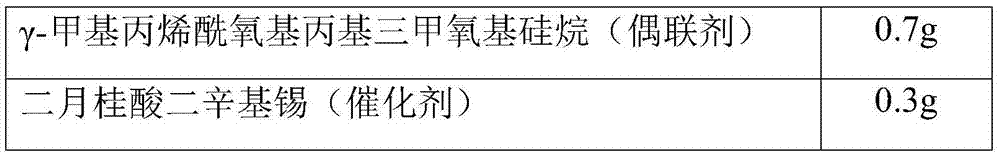

[0043] A low-density deketoxime type silicone sealant, which consists of the following components:

[0044] a,ω-Dihydroxypolydimethylsiloxane

100g

20g

Thermally expandable microcapsules F-78K

0.4g

Vinyl tributylketoxime silane (crosslinking agent)

2g

Methyltributylketoximosilane (crosslinking agent)

8g

Modified CaCO 3 (reinforcing filler)

120g

γ-aminopropyltriethoxysilane (coupling agent)

2.4g

Dioctyltin dilaurate (catalyst)

0.4g

[0045] The preparation method of the low-density deketoxime type silicone sealant is as follows:

[0046] A. 100 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20mpa·s, 20g of simethicone oil with a viscosity of 450pa·s, 0.4g of thermally expandable microcapsules F-78K, and 120g of modified CaCO 3 After mixing, put it into a planetary stirring tank for stirring, control the temperature at 140°C, and mix for 3 hours under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com