Silane-modified polyether adhesive for sealing fabricated concrete buildings and manufacturing method thereof

A technology of silane-modified polyether and concrete construction, which is applied in the field of sealant, which can solve the problems of sealant bond failure, affect the sealant bondability, and affect the sealant bond performance, etc., to achieve good adhesion and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

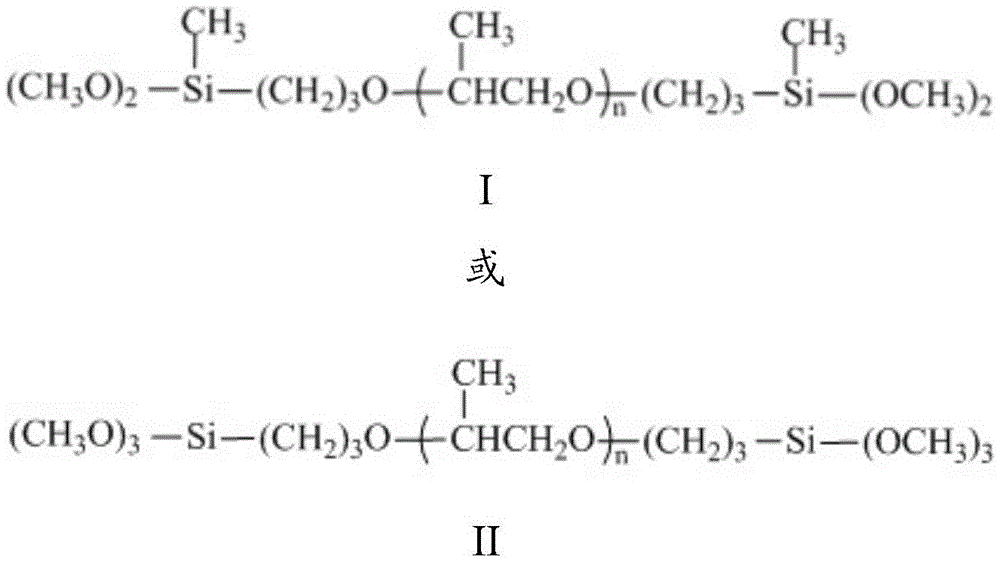

Method used

Image

Examples

Embodiment 1

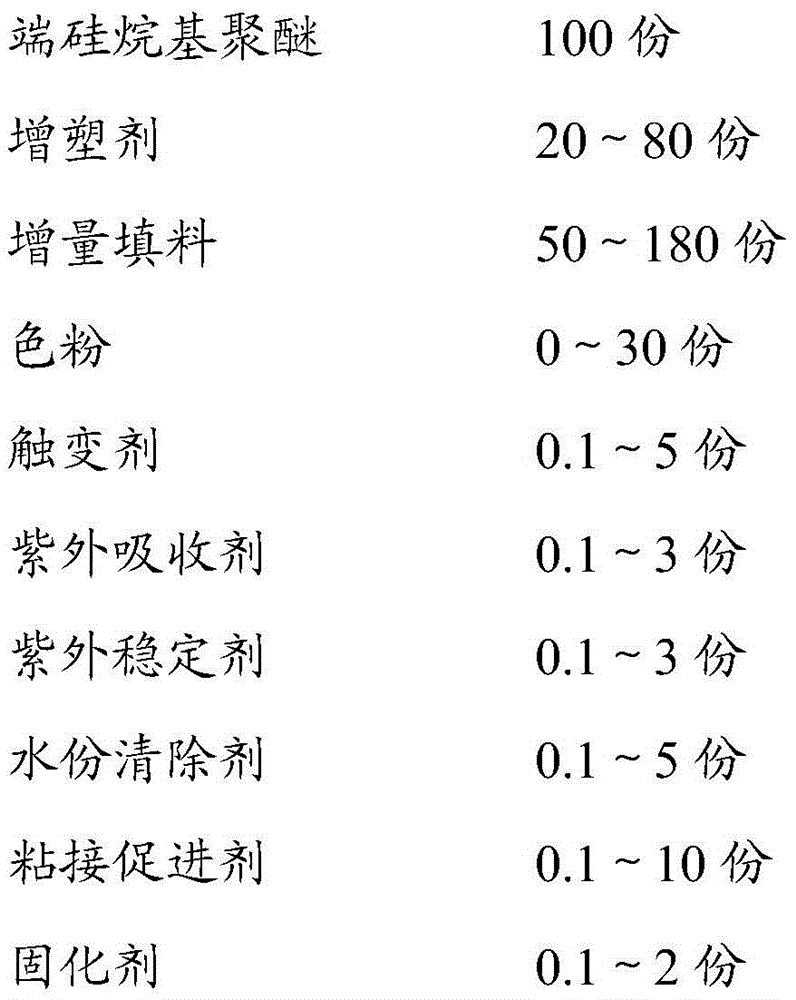

[0046] A silane-modified polyether adhesive used for sealing prefabricated concrete buildings is prepared from the following raw materials in parts by weight:

[0047]

[0048]

[0049] The silane-modified polyether glue used for the sealing of prefabricated concrete buildings in this embodiment is prepared by the following method:

[0050] Weigh the amount of silane-terminated polyether, plasticizer, extender filler, toner, UV absorber, UV stabilizer, and thixotropic agent in the formula, add them to the double planetary mixer in sequence, mix evenly, and keep the vacuum at -0.09 MPa~-0.1MPa, stir for 60min at a temperature of 60~90°C, then cool down to 50°C, then add moisture scavenger, adhesion promoter and curing agent, in a vacuum of -0.09MPa~-0.1 Under the condition of MPa, stir for 30 minutes to obtain.

Embodiment 2

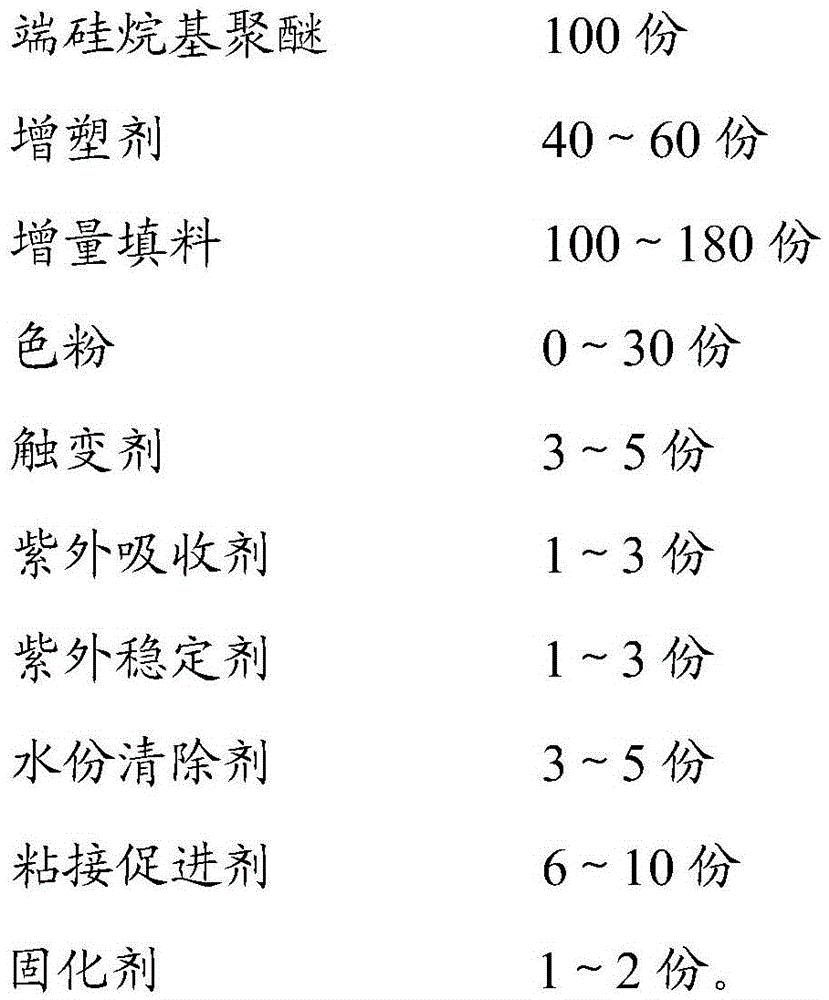

[0052] A silane-modified polyether adhesive used for sealing prefabricated concrete buildings is prepared from the following raw materials in parts by weight:

[0053]

[0054]

[0055] The silane-modified polyether glue used for the sealing of prefabricated concrete buildings in this embodiment is prepared by the following method:

[0056] Weigh the amount of silane-terminated polyether, plasticizer, extender filler, toner, UV absorber, UV stabilizer, and thixotropic agent in the formula, add them to the double planetary mixer in sequence, mix evenly, and keep the vacuum at -0.09 MPa~-0.1MPa, stir for 60min at a temperature of 60~90°C, then cool down to 50°C, then add moisture scavenger, adhesion promoter and curing agent, in a vacuum of -0.09MPa~-0.1 Under the condition of MPa, stir for 30 minutes to obtain.

Embodiment 3

[0058] A silane-modified polyether adhesive used for sealing prefabricated concrete buildings is prepared from the following raw materials in parts by weight:

[0059]

[0060] The silane-modified polyether glue used for the sealing of prefabricated concrete buildings in this embodiment is prepared by the following method:

[0061] Weigh the amount of silane-terminated polyether, plasticizer, extender filler, toner, UV absorber, UV stabilizer, and thixotropic agent in the formula, add them to the double planetary mixer in sequence, mix evenly, and keep the vacuum at -0.09 MPa~-0.1MPa, stir for 60min at a temperature of 60~90°C, then cool down to 50°C, then add moisture scavenger, adhesion promoter and curing agent, in a vacuum of -0.09MPa~-0.1 Under the condition of MPa, stir for 30 minutes to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com