One-component alcohol sealant for photovoltaic assembly and preparation technology thereof

A photovoltaic module, one-component technology, used in adhesives, other chemical processes, adhesive additives, etc., can solve problems such as corrosion and affect the performance of photovoltaic modules, and achieve improved adhesion, excellent adhesion, flame retardant and thermal conductivity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

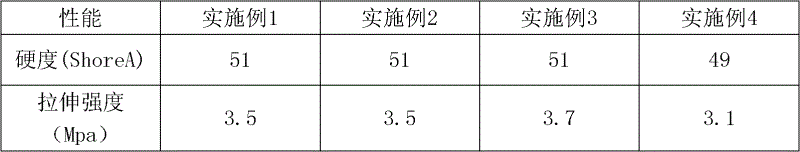

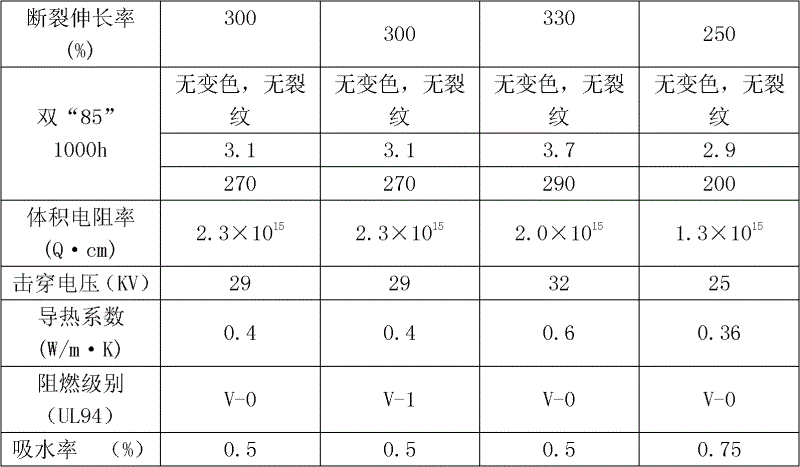

[0066] 50 parts of α, ω-terminated hydroxyl polydimethylsiloxane, 50 parts of α, ω-aminopropyldiethoxysiloxy-terminated polydimethylsiloxane, 100 parts of surface-treated Alumina, 50 parts of activated aluminum hydroxide, 10 parts of MQ silicone resin and 100 parts of activated calcium carbonate were added to the vacuum kneader, the temperature was controlled at 150 °C, the vacuum degree was 0.1 MPa, blended and dehydrated for 4 hours, and the base rubber was made. Then transfer to a high speed mixer. At room temperature, mix 10 parts of α, ω-alkoxypolydimethylsiloxane, 10 parts of methyltrimethoxysilane, 0.8 parts of platinum complex and 1 part of bis(trimethoxysilylpropyl) ammonia , 2 parts of γ-(2,3-glycidoxy) propyltrimethoxysilane, 6 parts of ethyl acetoacetate chelate of isopropyl titanate and 0.1 part of dibutyltin dilaurate were added at high speed In the disperser, stir with the base gum under vacuum. The vacuum degree is 0.1 MPa, the rotation speed is 50 rpm, and t...

Embodiment 2

[0068] Embodiment 2: The proportion and process are the same as in Embodiment 1, and no platinum-vinylsiloxane complex is added in the formula. Compared with Example 1, without adding platinum or platinum complex, its flame retardant performance drops to V1 level. Therefore, adding a small amount of platinum can greatly improve the flame retardant performance, which can reach the UL94-V0 level.

Embodiment 3

[0069] Embodiment 3: The proportion and process are the same as in Embodiment 1, with 100 parts of alumina replaced by 200 parts of boron nitride. The performance test results are shown in Table 1. Compared with Example 1, the use of boron nitride instead of alumina improves the thermal conductivity to a certain extent, and the thermal conductivity increases from 0.4W / m·K to 0.6W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com