Bi-component room-temperature cured silicone sealant

A room temperature curing and sealant technology, applied in the field of sealants, can solve the problems of unsatisfactory curing speed and unsatisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

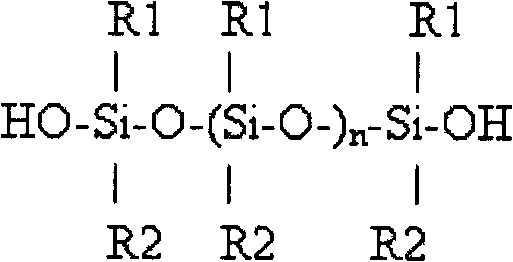

Method used

Image

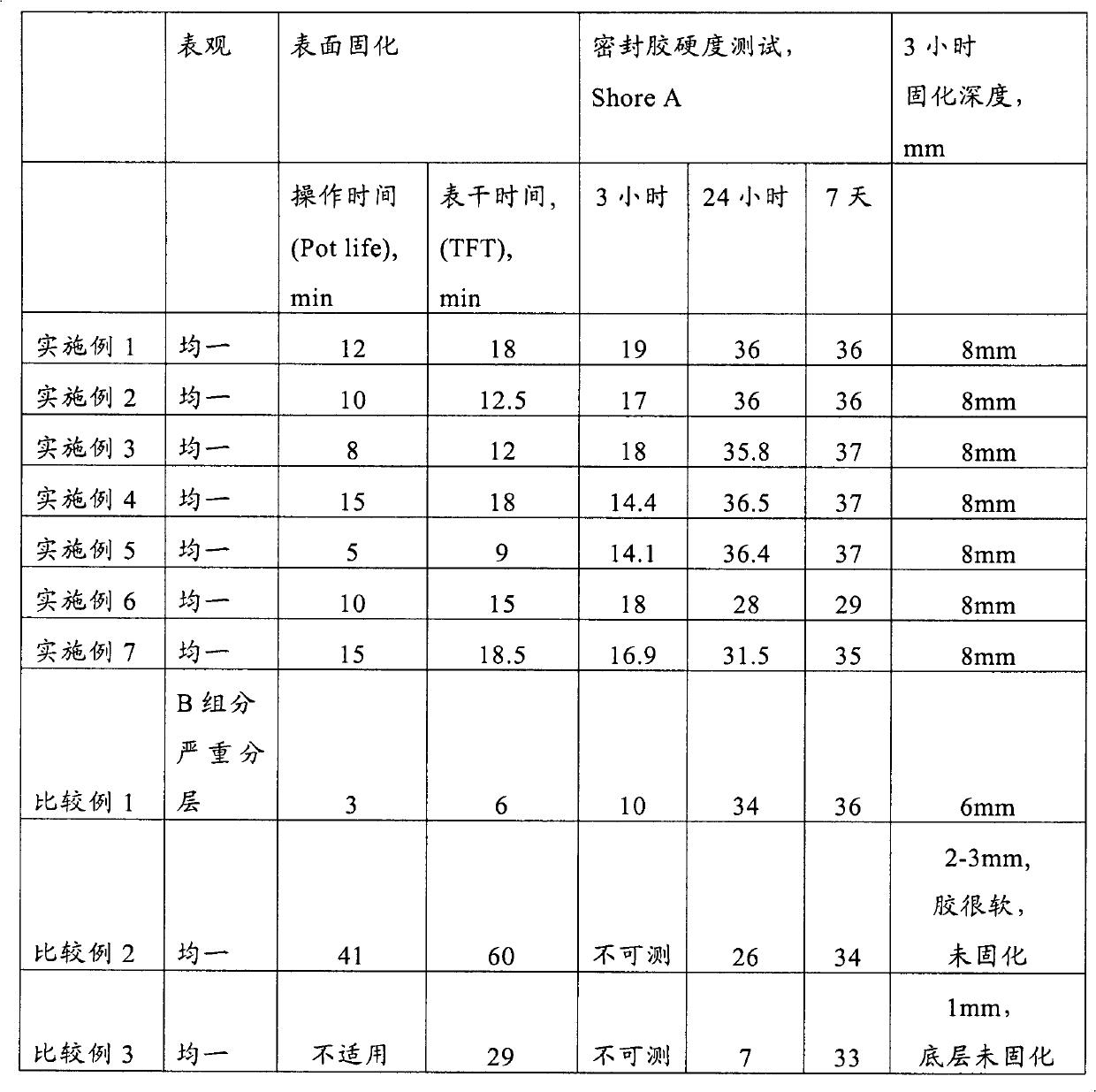

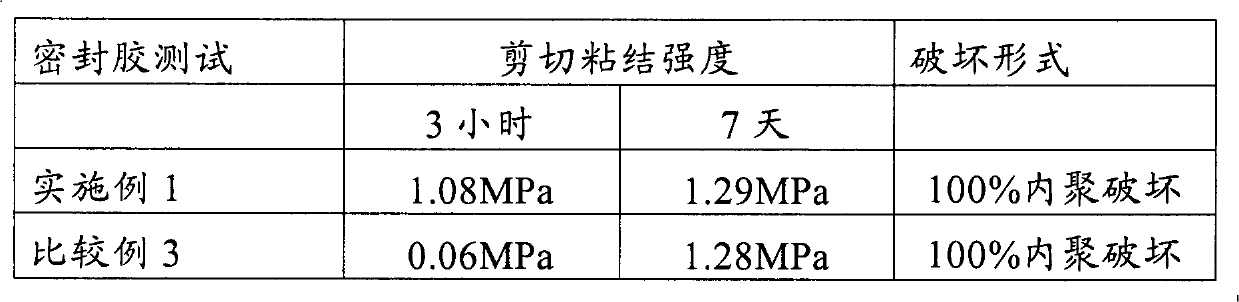

Examples

Embodiment 1

[0081] Preparation of component A of two-component room temperature curing sealant

[0082] 45 parts by weight of hydroxyl-terminated polydimethylsiloxane (107 glue, 20,000 centipoise), methyl-terminated polydimethylsiloxane (201 silicone oil, viscosity of 1000 centipoise; 10 parts by weight; filler: calcium carbonate powder 45 parts by weight, uniformly mixed in a mixer, packed for later use.

[0083] Preparation of component B of two-component room temperature curing sealant

[0084] Under water-proof conditions, first mix 57 parts by weight of methyl-terminated polydimethylsilicone oil (201 silicone oil), 7 parts by weight of white carbon black that has been surface-treated, vacuumize, dehydrate and mix; add methyl trimethicone after cooling to room temperature 25 parts by weight of a mixture of ethoxysilane and methyl tributylketoxime silane 1:1 (weight ratio), vacuumize and mix; finally add the silane adhesion promoter γ-aminopropyltriethoxysilane (AMEO ) and 10 parts b...

Embodiment 2

[0086] Keeping the other components in Example 1 unchanged, only the crosslinking agent in component B was replaced with a mixture of tetraethoxysilane and methyltributanoximinosilane at a ratio of 1:1 (by weight).

Embodiment 3

[0088] Keeping the other components in Example 1 unchanged, only the crosslinking agent in component B was replaced by a mixture of methyltriethoxysilane and methyltributanoximinosilane in a ratio of 2:3 (by weight).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com