Sewage treatment method and system used by same

A sewage treatment method and sewage treatment system technology, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. Low interception rate and other issues, to achieve the effect of reducing production costs, good actual treatment effect, and zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

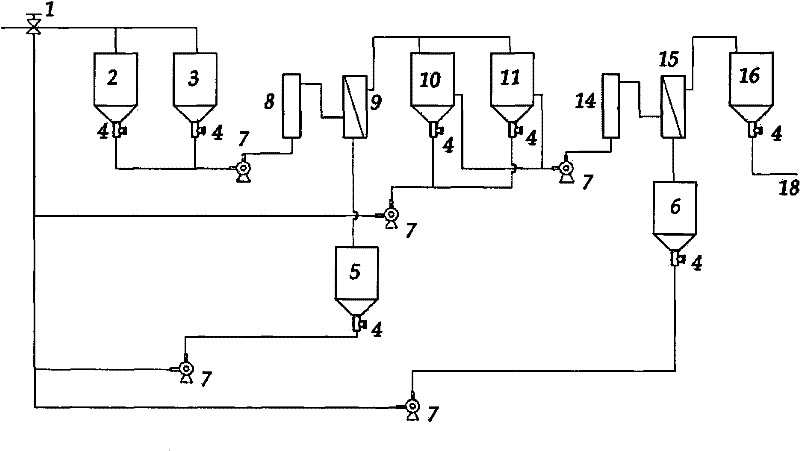

[0069] figure 2 It is a schematic diagram of a sewage treatment system provided by the present invention. The sewage treatment system of the present invention comprises:

[0070] The primary water storage tanks 2 and 3 are used to store raw sewage water;

[0071] The nanofiltration membrane unit 9 is connected to the primary water storage tanks 2 and 3, and is used to carry out the concentration and filtration of the primary nanofiltration membrane to the above-mentioned sewage. Sales of commercial nanofiltration membranes;

[0072] The first static storage tank 5, which is connected to the nanofiltration membrane unit 9, is used to add crystal seeds to the sewage concentrated by the nanofiltration membrane to induce crystallization;

[0073] The secondary water inlet storage tanks 10 and 11, which are connected to the nanofiltration membrane unit 9, are used to store the above-mentioned sewage filtered through the nanofiltration membrane, and are the water inlet tanks of ...

Embodiment 12

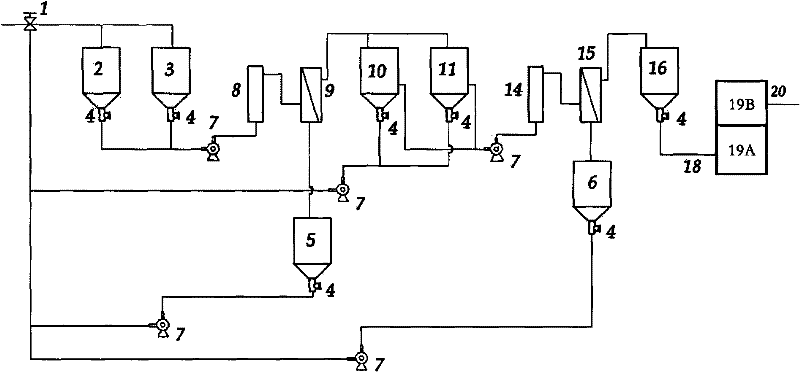

[0081] image 3 It is a schematic diagram of another sewage treatment system provided by the present invention. and figure 2 Compared to the system shown in the image 3 The shown sewage treatment system also includes a cation exchange resin 19A, an anion exchange resin 19B and an outlet pipeline 20. The cation exchange resin 19A is connected to the outlet water storage tank 16 through a pipeline 18, and the anion exchange resin 19B is connected to the outlet pipeline 20.

Embodiment 13

[0083] Figure 4 It is a schematic diagram of another sewage treatment system provided by the present invention. and image 3 Compared to the system shown in the Figure 4 The shown sewage treatment system also includes an activated carbon treatment unit 19C, wherein the cation exchange resin 19A is connected to the effluent storage tank 16 through a pipeline 18, the cation exchange resin 19A, the anion exchange resin 19B are connected to the activated carbon treatment unit 19C, and the activated carbon treatment unit 19C is connected to the effluent storage tank 16. Line 20 is connected. It should be understood that the activated carbon treatment unit 19C of the present embodiment and the cation exchange resin 19A and the anion exchange resin 19B of the embodiment 1.2 may not be used at the same time, that is, the activated carbon treatment unit 19C of the present embodiment may be used separately with figure 2 The systems shown are used in combination.

[0084] The sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com