Solar energy industrial heat conduction oil heating comprehensive system

A technology of an integrated system and a solar collector, which is applied in the field of integrated thermal oil heating systems in the solar industry, can solve problems such as increasing production costs, consuming large combustible resources, and air pollution, and achieves improved convenience, high energy utilization, and improved Use effect and life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

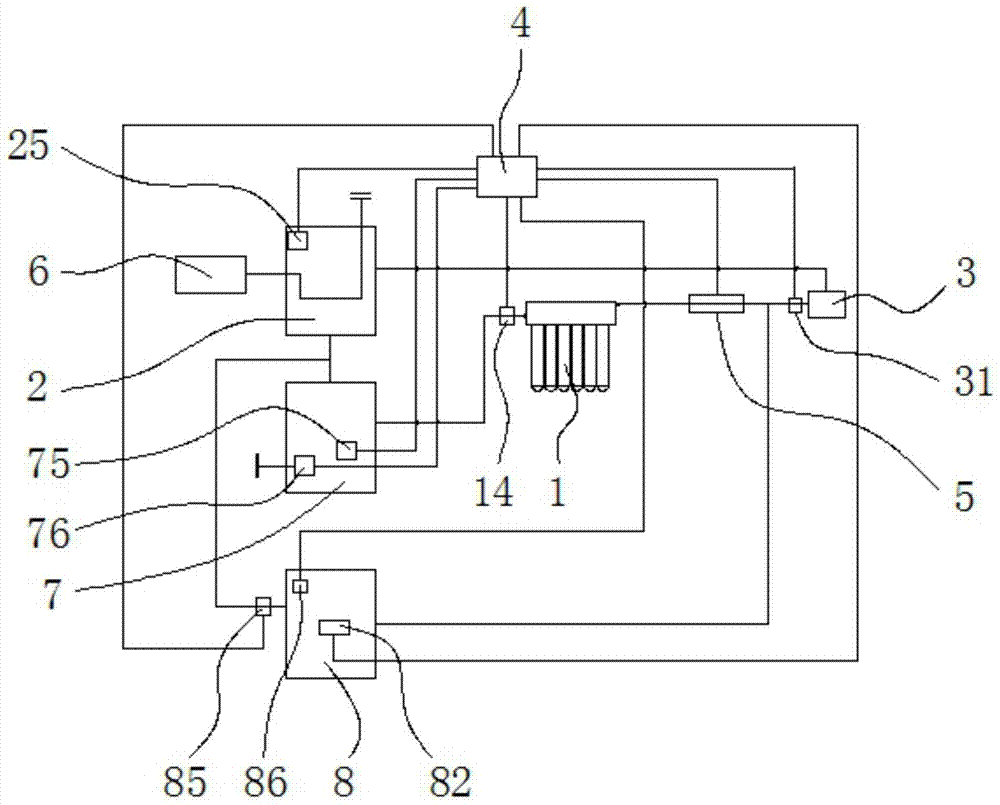

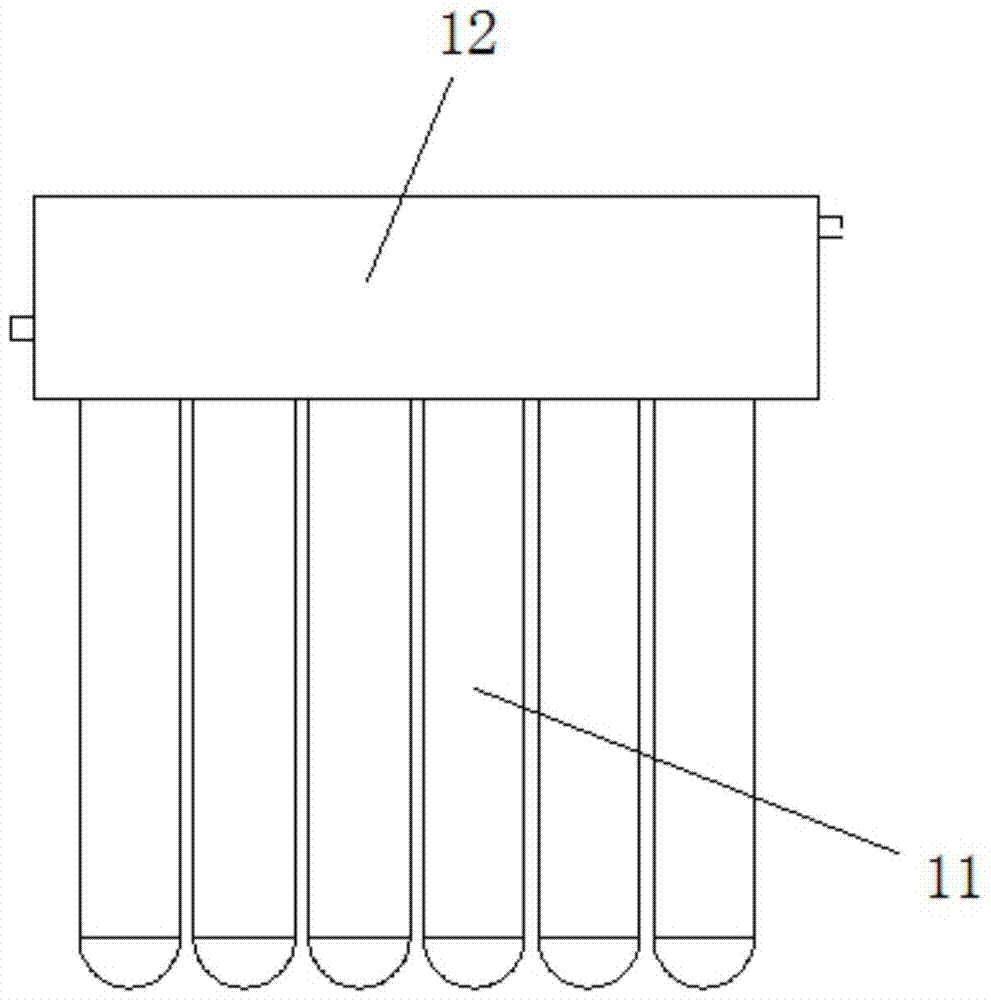

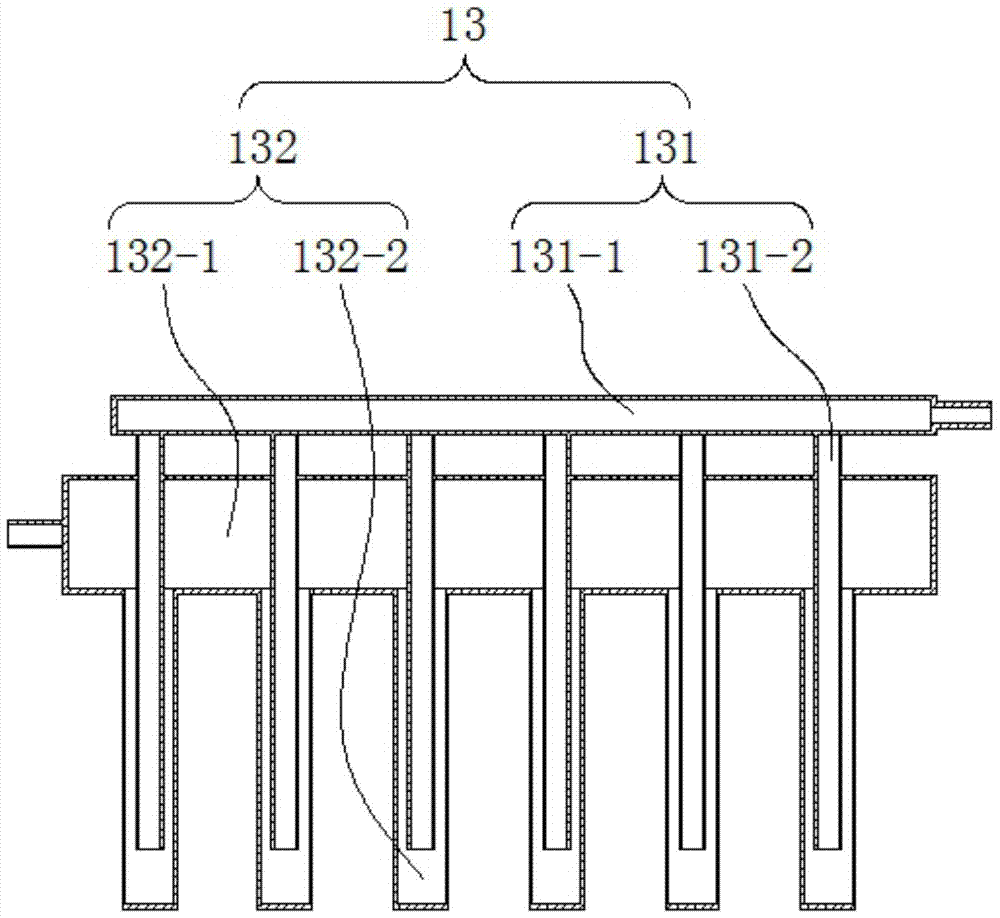

[0021] See Figure 1 to Figure 6 , the present invention has a solar heat collector 1, a heat transfer oil tank 2 and a heat transfer oil application unit 3; the solar heat collector 1 includes a plurality of vacuum tubes 11, a header 12 and a heat collection tube group 13; the heat collection tube group 13 is set In the header 12, the vacuum tubes 11 are arranged side by side on the header 12; the heat collecting tube group 13 includes a liquid inlet pipe group 131 and a liquid outlet pipe group 132; the liquid inlet pipe group 131 includes a liquid inlet main pipe 131- 1 and a plurality of liquid inlet branch pipes 131-2 connected side by side on the liquid inlet main pipe 131-1; The liquid outlet branch pipe 132-2 on the top; one end of the liquid inlet main pipe 131-1 is closed, and the other end is a liquid inlet; one end of the liquid inlet branch pipe 131-2 is connected to the liquid inlet main pipe 131-1, and the other One end is open; one end of the liquid outlet mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com