Automatic continuous powder metering and feeding system and method for production of sealants

An automatic metering and feeding system technology, which is applied in the field of silicone sealant production and feeding devices, can solve problems such as the inability to accurately control the powder raw materials, fluctuations in the amount of addition, and metering deviations, and achieve simple structure, reduced errors, and accurate metering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

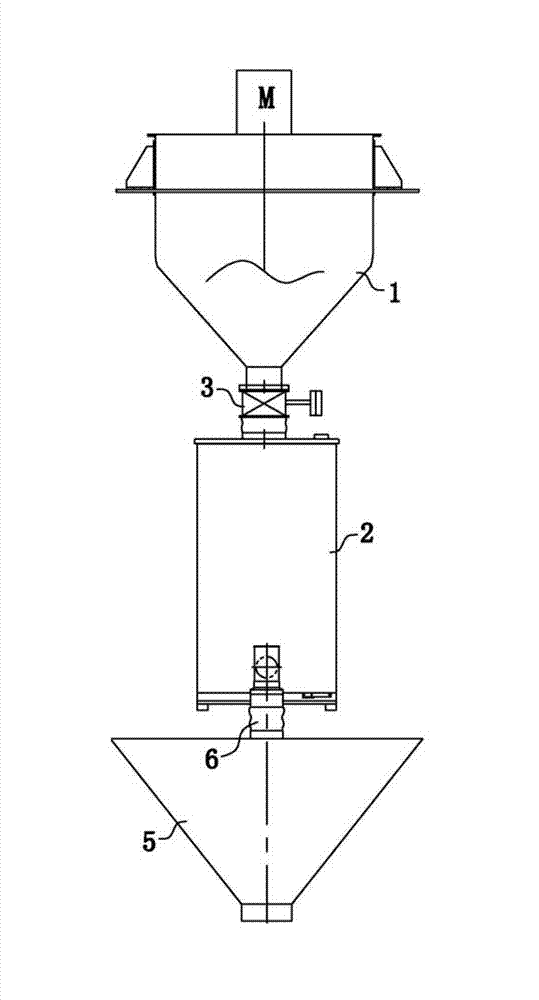

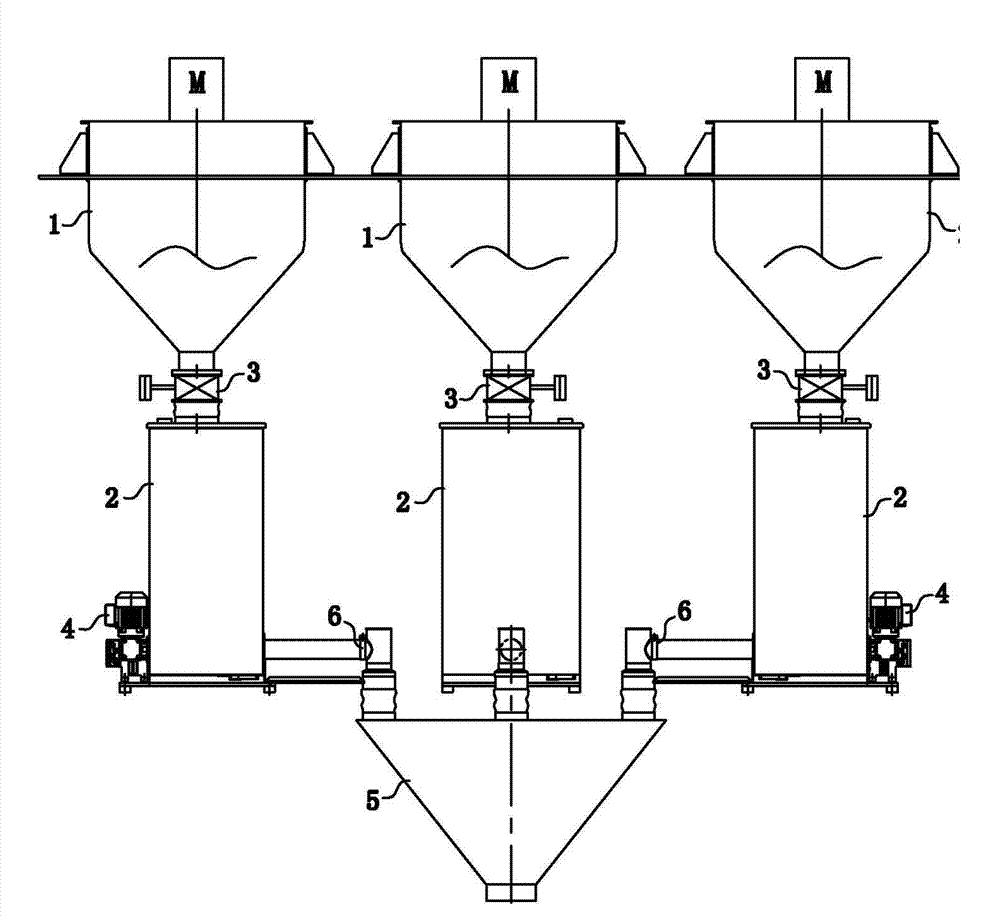

[0020] Before explaining the technical scheme of the present invention in detail, an important component in the system of the present invention, the loss-in-weight scale, will be described first:

[0021] The loss-in-weight scale is a weighing device that feeds intermittently and discharges continuously. Because the loss control is carried out in the storage tank, it can achieve high control accuracy, and its structure is easy to seal, so it is relatively good in powder control performance. Excellent, suitable for controlling batching of fine materials such as cement, lime powder, coal powder, etc. According to the reduction rate of the material weight in the storage tank, the discharge screw machine or the electric vibrator is controlled to achieve the purpose of quantitative feeding. When the material in the storage tank reaches the lower limit of weighing, the discharge screw machine The rotating speed is fixed, and the material in the upstream equipment is quickly lowered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com