Single-component dealcholization-type silicon sealant used for automobile lamp and preparation method thereof

A silicone sealant, dealcoholized technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of polluting car lights, etc., achieve no oil leakage, fast curing speed, and enhanced bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

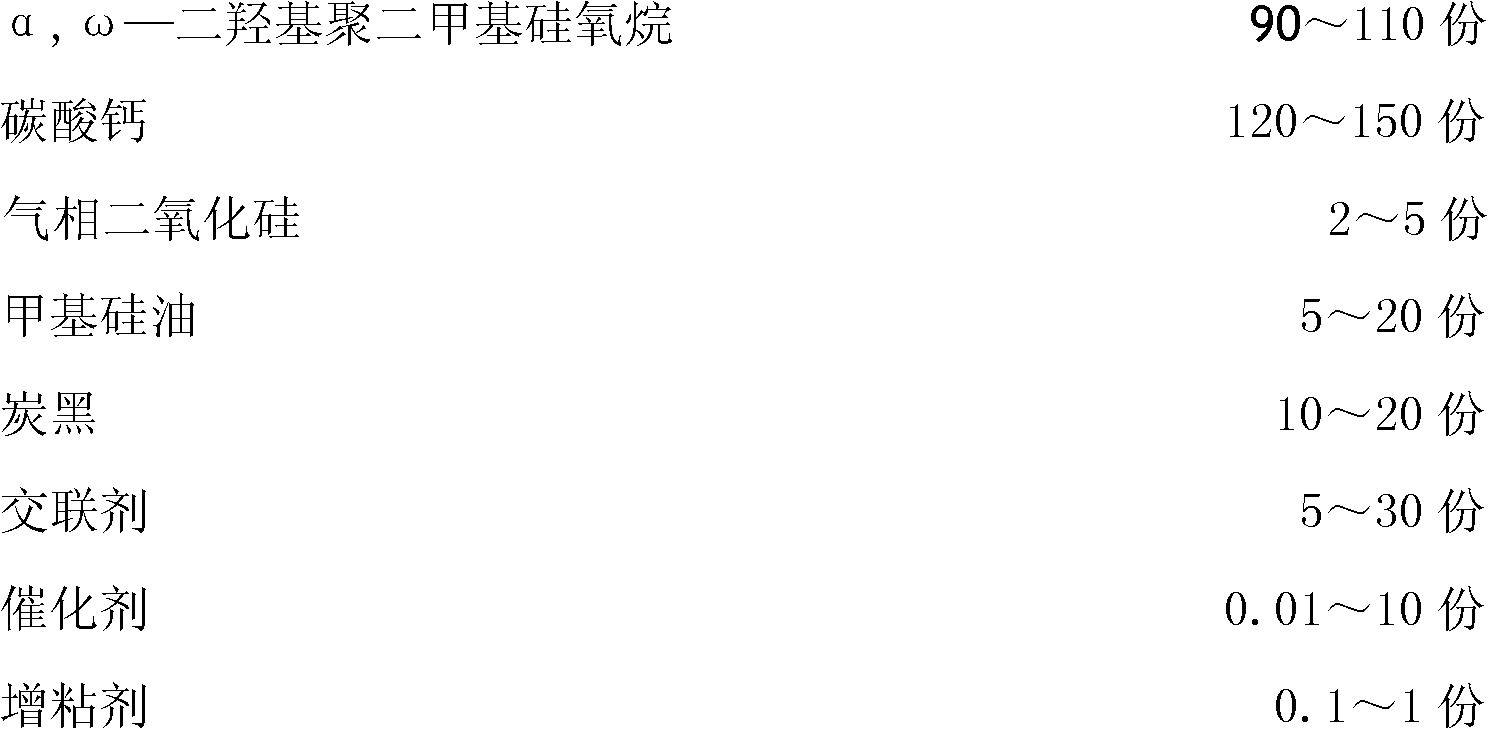

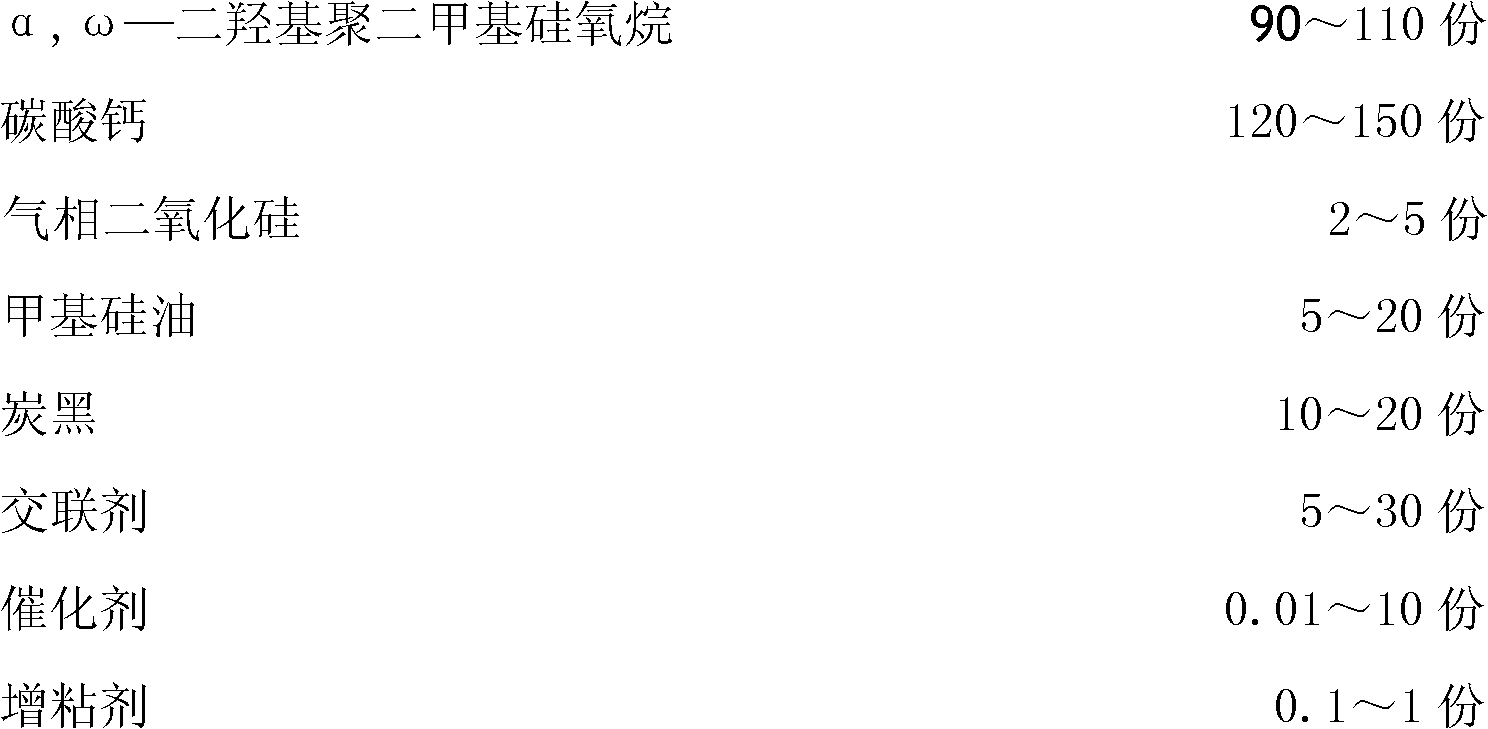

Method used

Image

Examples

Embodiment 1

[0021] Take α, ω-dihydroxy polydimethylsiloxane at 25°C, the viscosity at 25°C is 15000mPa·s, take 100 parts, 150 parts of pre-dried calcium carbonate, 20 parts of carbon black, methyl 5 parts of silicone oil, 20 parts of vinyl trimethoxysilane, 4 parts of fumed silica, 0.1 part of n-butyl titanate, 0.2 parts of aminopropyl triethoxysilane and 0.3 parts of glycidoxypropyl trimethoxysilane part of the mixture as a tackifier. Stir and mix for 40 minutes at a vacuum of 0.06Mpa, remove low-molecular substances at a vacuum of 0.08Mpa, and then discharge and fill.

Embodiment 2

[0023] Take 90 parts of α, ω-dihydroxy polydimethylsiloxane, whose viscosity is 80000mPa·s at a temperature of 25°C, 120 parts of pre-dried calcium carbonate; 10 parts of carbon black, 20 parts of dimethyl silicone oil 10 parts of methyltrimethoxysilane, 2 parts of fumed silica, 0.1 part of n-butyl titanate, 0.2 part of aminopropyltriethoxysilane and 0.3 part of aminoethylaminopropyltrimethoxysilane Make a tackifier. Stir and mix for 30 minutes at a vacuum of 0.1Mpa, remove low-molecular substances at a vacuum of 0.1Mpa, and then discharge and fill.

Embodiment 3

[0025] Take 100 parts of α, ω-dihydroxypolydimethylsiloxane, whose viscosity is 45000mPa·s at a temperature of 25°C, 140 parts of pre-dried calcium carbonate, 15 parts of carbon black, and 12 parts of methyl silicone oil , 15 parts of ethyl silicate, 3 parts of fumed silica, 0.05 part of ethyl acetoacetate isopropyl titanate chelate, 0.05 part of n-butyl titanate, 0.3 part of n-butylaminopropyl trimethoxysilane and A mixture of 0.2 parts of aminoethylaminopropyltrimethoxysilane is used as a tackifier. Stir and mix for 35 minutes at a vacuum of 0.08Mpa, remove low-molecular substances at a vacuum of 0.09Mpa, and then discharge and fill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com