Silicone sealant polymer capable of self-repairing and being recycled by virtue of sunlight as well as preparation method and application of silicone sealant polymer

A technology of silicone glue and polymer, which is applied in the field of green polymer materials, can solve the problems of material macroscopic fracture, fatigue damage, crack expansion, etc., and achieve the effects of short repair time, extended service life and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

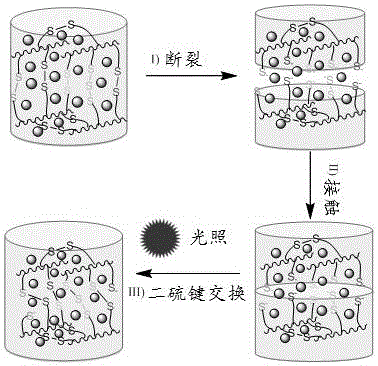

Method used

Image

Examples

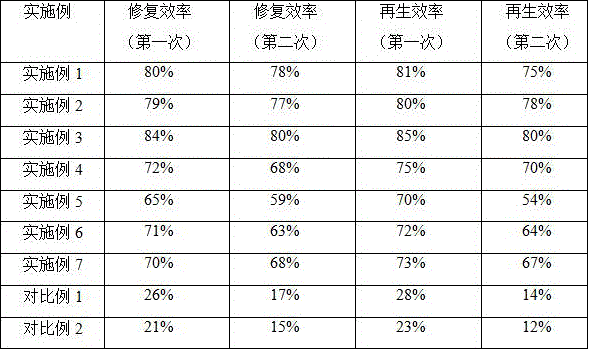

Embodiment 1

[0050] Take the following raw materials in parts by weight: 100 parts of α, ω-dihydroxypolysiloxane with a viscosity of 3000cst, 10 parts of bis-3-(triethoxysilylpropyl)-disulfide, 5 parts of Silicone resin of sulfur bond or tetrasulfide bond, 3 parts of surface modified nano silica (100 parts by weight of nano silicon dioxide, 15 parts by weight of silane coupling agent, 500 parts by weight of ethanol solution, grafting rate of 8%), 3 parts by weight Dibutyltin dilaurate; first the α, ω-dihydroxy polysiloxane with the viscosity of 3000cst is stirred and mixed with surface-modified nano silicon dioxide, silicone resin containing disulfide bonds or tetrasulfide bonds, and then Add bis-3-(triethoxysilylpropyl)-disulfide, stir and mix well, then add dibutyltin dilaurate, stir and mix well, then degas the above mixture under vacuum conditions, and then put it into a container Sealed and stored, it is a silicone rubber prepolymer. After extruding the prepared silicone rubber prepo...

Embodiment 2

[0056] Take the following raw materials in parts by weight: 100 parts of α, ω-dihydroxypolysiloxane with a viscosity of 3000cst, 5 parts of bis-[γ-(triethoxysilyl) propyl] tetrasulfide, 5 parts containing Silicone resin of disulfide bond or tetrasulfide bond, 3 parts of surface modified nano-silica (100 parts by weight of nano-silica, 15 parts by weight of silane coupling agent, 500 parts by weight of ethanol solution, grafting rate of 8%), 3 parts of dibutyltin dilaurate; the α, ω-dihydroxy polysiloxane with the viscosity of 3000cst is stirred and mixed evenly with surface-modified nano silicon dioxide, silicone resin containing disulfide bond or tetrasulfide bond, Then add bis-[γ-(triethoxysilyl)propyl]tetrasulfide and stir to mix evenly, then add dibutyltin dilaurate and stir to mix evenly, then degas the above mixture under vacuum conditions, and then pack Put it into a container and keep it sealed, which is the silicone rubber prepolymer. After the prepared silicone rubb...

Embodiment 3

[0062] Take the following raw materials in parts by weight: 100 parts of α, ω-dihydroxypolysiloxane with a viscosity of 1500cst, 10 parts of bis-3-(triethoxysilanepropyl)-disulfide, 10 parts of Silicone resin with sulfur bond or tetrasulfide bond, 1 part of surface modified nano-silica (100 parts by weight of nano-silica, 10 parts by weight of silane coupling agent, 500 parts by weight of ethanol solution, grafting rate 5%), 5 parts by weight Dibutyltin dilaurate; First, the α, ω-dihydroxy polysiloxane with the viscosity of 1500cst is stirred and mixed with surface-modified nano silicon dioxide, silicone resin containing disulfide bonds or tetrasulfide bonds, and then Add bis-3-(triethoxysilylpropyl)-disulfide, stir and mix well, then add dibutyltin dilaurate, stir and mix well, then degas the above mixture under vacuum conditions, and then put it into a container Sealed and stored, it is a silicone rubber prepolymer. After the prepared silicone rubber prepolymer is extruded,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com