Immersion-resistant single-component deacidified organic silicon sealant composition and preparation method thereof

A composition and silicone technology, applied in chemical instruments and methods, adhesives, adhesive additives, etc., can solve the problems of small displacement capacity, water leakage, failure to achieve air tightness, water tightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

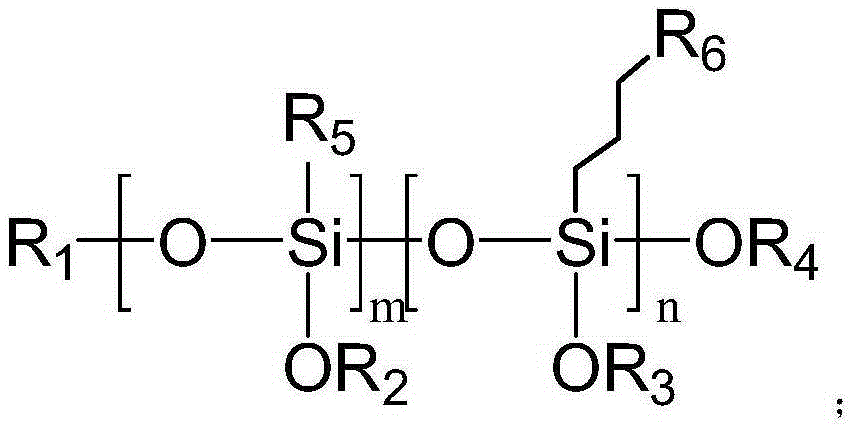

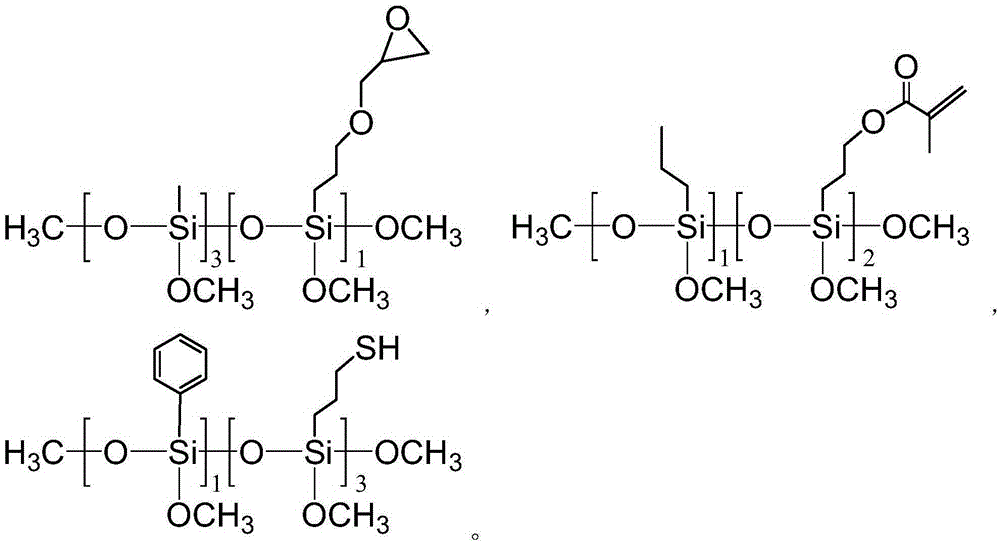

[0077] Example 1: 50 parts by mass of α with a viscosity of 10000mPa·s, and 50 parts by mass of ω-dihydroxypolydimethylsiloxane with a viscosity of 50000mPa·s, 50 parts by mass of ω-dihydroxypolydimethylsiloxane , specific surface area 200m 2 20 parts by mass of fumed silica per g, 20 parts by mass of polydimethylsiloxane with a viscosity of 100 mPa·s, 3 parts by mass of methyltriacetoxysilane, and 5 parts by mass of dimethyldiacetoxysilane Add it into a mixer, stir and mix for 60 minutes under a vacuum of 0.06MPa; add 0.05 parts by mass of dibutyltin dilaurate, 0.05 parts by mass of stannous octoate, 0.1 parts by mass of butyl titanate, and 2 parts by mass of dodecyltrimethoxysilane Parts, 3 parts by mass of hexadecyltrimethoxysilane, the structural formula is Add 0.2 parts by mass of the tackifier to the mixer, stir and mix for 60 minutes at a temperature of 30°C and a vacuum of 0.085 MPa to obtain a water-resistant one-component deacidification type silicone sealant compo...

Embodiment 2

[0080] Example 2: 30 parts by mass of α with a viscosity of 5000mPa·s, 30 parts by mass of ω-dihydroxypolydimethylsiloxane and 30 parts by mass of α with a viscosity of 20000mPa·s , 40 parts by mass of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 80000mPa·s, and a specific surface area of 50m 2 5 parts by mass of fumed silica per g, 10 parts by mass of polydimethylsiloxane with a viscosity of 500mPa·s, 1 part by mass of ethyltriacetoxysilane, and 4 parts by mass of vinyltriacetoxysilane In a mixer, stir and mix for 80 minutes under a vacuum of 0.085 MPa; 0.03 parts by mass of dibutyltin diacetate, 1 part by mass of octyltriethoxysilane, and 1 part by mass of hexadecyltrimethoxysilane, the structural formula is Add 1 mass part of the tackifier to the mixer, stir and mix for 90 minutes at a temperature of 20°C and a vacuum of 0.09MPa to obtain a water-resistant one-component deacidification type silicone sealant composition. The test results of product performance a...

Embodiment 3

[0083] Example 3: 100 parts by mass of α, ω-dihydroxypolydimethylsiloxane with a specific surface area of 100 m 2 30 parts by mass of fumed silica per g, 25 parts by mass of polydimethylsiloxane with a viscosity of 200mPa·s, 4 parts by mass of methyltriacetoxysilane, 4 parts by mass of ethyltriacetoxysilane, Add 4 parts by mass of di-tert-butoxydiacetoxysilane into the mixer, and stir and mix for 30 minutes under a vacuum of 0.09 MPa; 0.1 part by mass of dibutyltin dioctoate, 0.1 part by mass of butyl titanate, 0.3 parts by mass of propyl ester, 1 part by mass of octyltrimethoxysilane, and the structural formula is Add 0.5 parts by mass of the tackifier to the mixer, stir and mix for 45 minutes at a temperature of 40°C and a vacuum of 0.08MPa to obtain a water-resistant one-component deacidification type silicone sealant composition. The test results of product performance are shown in the table. 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com