Condensed type double-component silicone sealant and preparation method thereof

A silicone sealant, two-component technology, applied in the field of materials, can solve the problems of low strength, softening of vulcanizate, performance impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

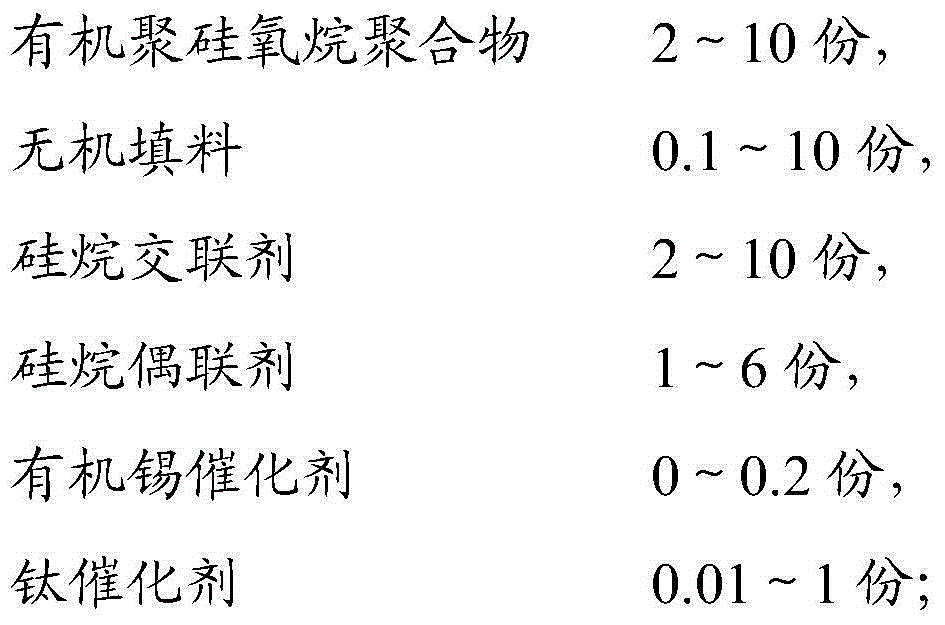

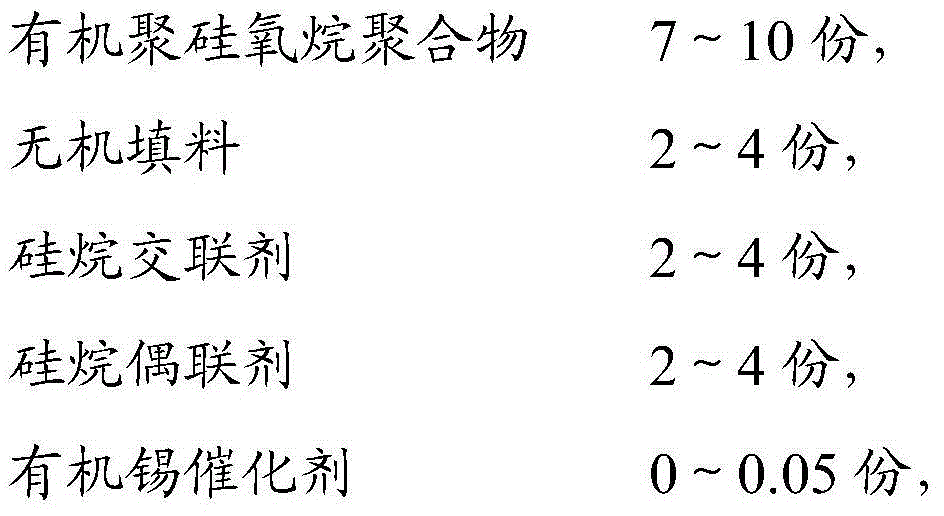

[0076] In this embodiment, a condensation-type two-component silicone sealant is prepared from the following raw materials in parts by weight:

[0077] Component A: 90 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa.s, 10 parts of simethicone oil with a viscosity of 100mPa.s, and 100 parts of nano-active calcium carbonate.

[0078] Component B: 8 parts of simethicone oil with a viscosity of 1000mPa.s, 3 parts of carbon black, 2 parts of ethyl orthosilicate, 1 part of methyl triethoxysilane, 2 parts of aminopropyl triethoxysilane, 1 part of γ-glycidyl etheroxypropyltrimethoxysilane, 0.02 part of dibutyltin dilaurate, and 0.5 part of isobutyl titanate.

[0079] The preparation method of the above-mentioned condensation type two-component silicone sealant is as follows:

[0080] Component A: Add α, ω-dihydroxypolydimethylsiloxane, nano-active calcium carbonate, and simethicone oil to the twin-screw extruder after the metering system is accurately metered...

Embodiment 2

[0084] In this embodiment, a condensation-type two-component silicone sealant is prepared from the following raw materials in parts by weight:

[0085] Component A: 90 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 12000mPa.s, 10 parts of simethicone oil with a viscosity of 350mPa.s, 80 parts of nano-active calcium carbonate, and 40 parts of heavy calcium carbonate .

[0086] Component B: 8 parts of dimethyl silicone oil with a viscosity of 10000mPa.s, 1 part of fumed silica, 2 parts of carbon black, 2 parts of propyl orthosilicate, methyltriethoxysilane oligomer (polymerization degree 2) 1 part, 2 parts of N-β aminoethyl γ-aminopropyl trimethoxysilane, 1 part of γ-glycidyloxypropyl trimethoxysilane, 0.4 part of isopropyl titanate.

[0087] The preparation method of the above-mentioned condensation type two-component silicone sealant is as follows:

[0088] Component A: Add α,ω-dihydroxy polydimethylsiloxane, nano-active calcium carbonate, heavy calcium car...

Embodiment 3

[0092] In this embodiment, a condensation-type two-component silicone sealant is prepared from the following raw materials in parts by weight:

[0093] Component A: 60 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 50000mPa.s, 25 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa.s, a viscosity of 1000mPa.s 15 parts of simethicone oil, 90 parts of nano-active calcium carbonate, and 40 parts of heavy calcium carbonate.

[0094] Component B: 8 parts of simethicone oil with a viscosity of 4000mPa.s, 1 part of fumed silica, 2 parts of carbon black, 2 parts of propyl orthosilicate, 1 part of methyl trimethoxysilane, aminopropyl trimethoxysilane 2 parts of ethoxysilane, 1 part of epoxycyclohexyltrimethoxysilane, 0.02 part of dioctyltin dilaurate, and 0.8 part of diisopropoxytitanium bis(β-diketone ester) complex.

[0095] The preparation method of the above-mentioned condensation type two-component silicone sealant is as follows:

[0096] Compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com