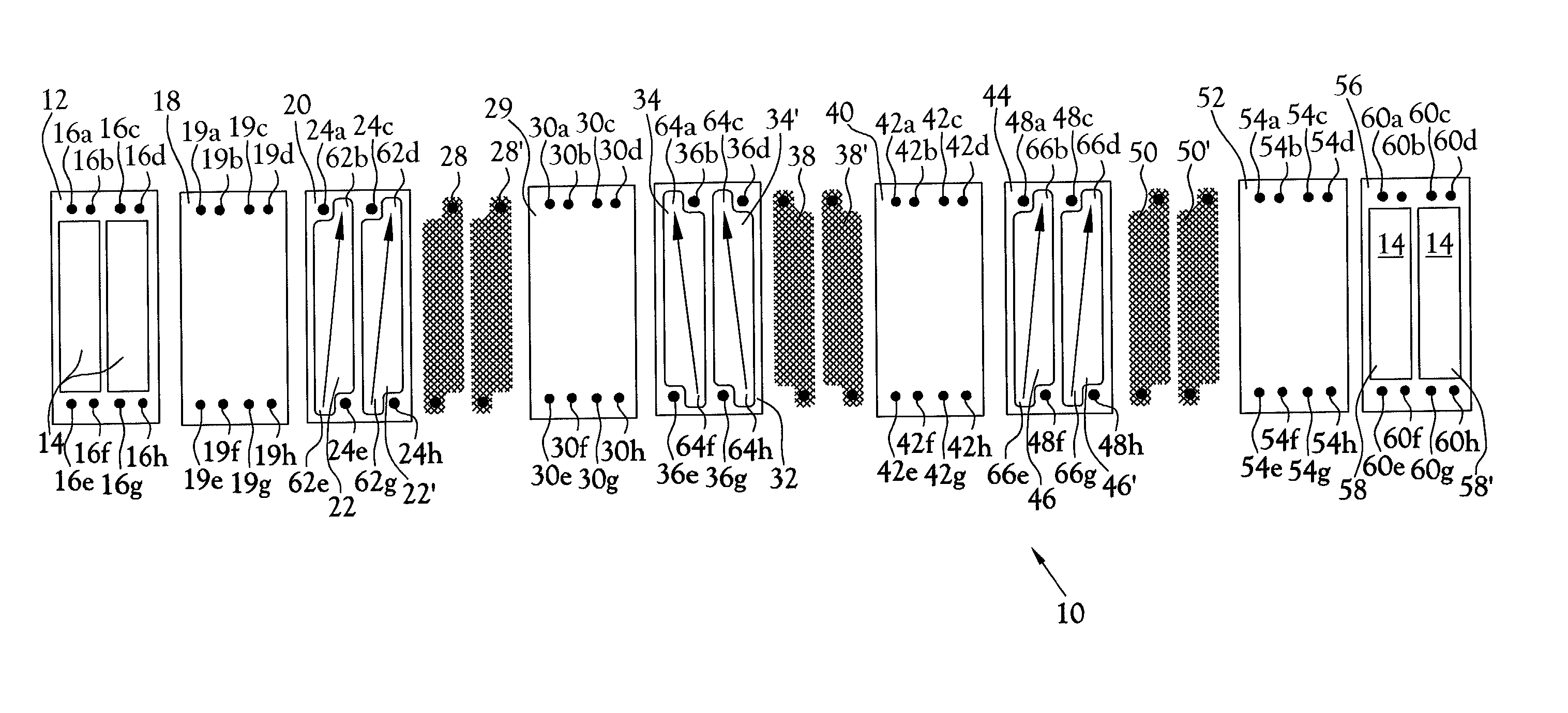

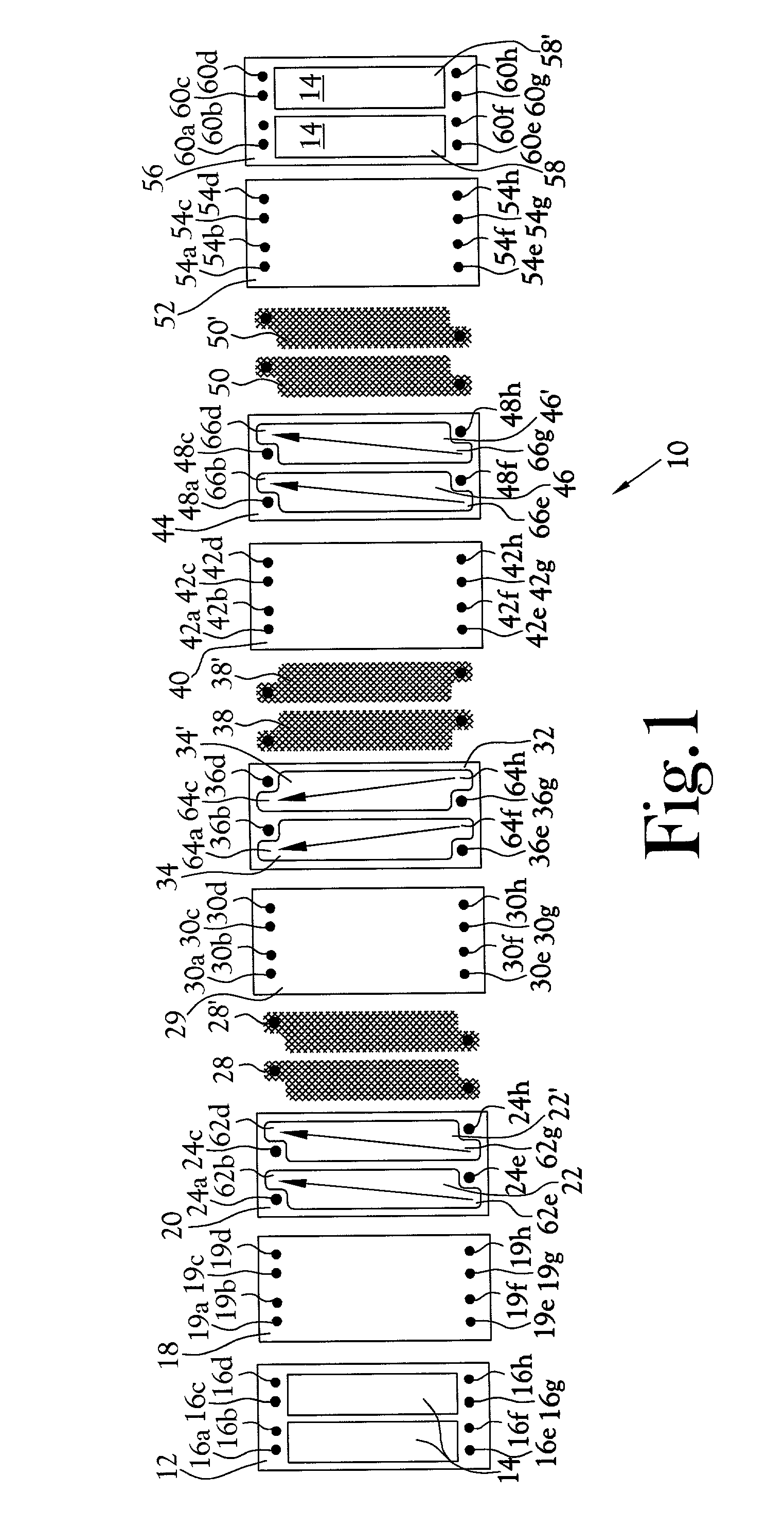

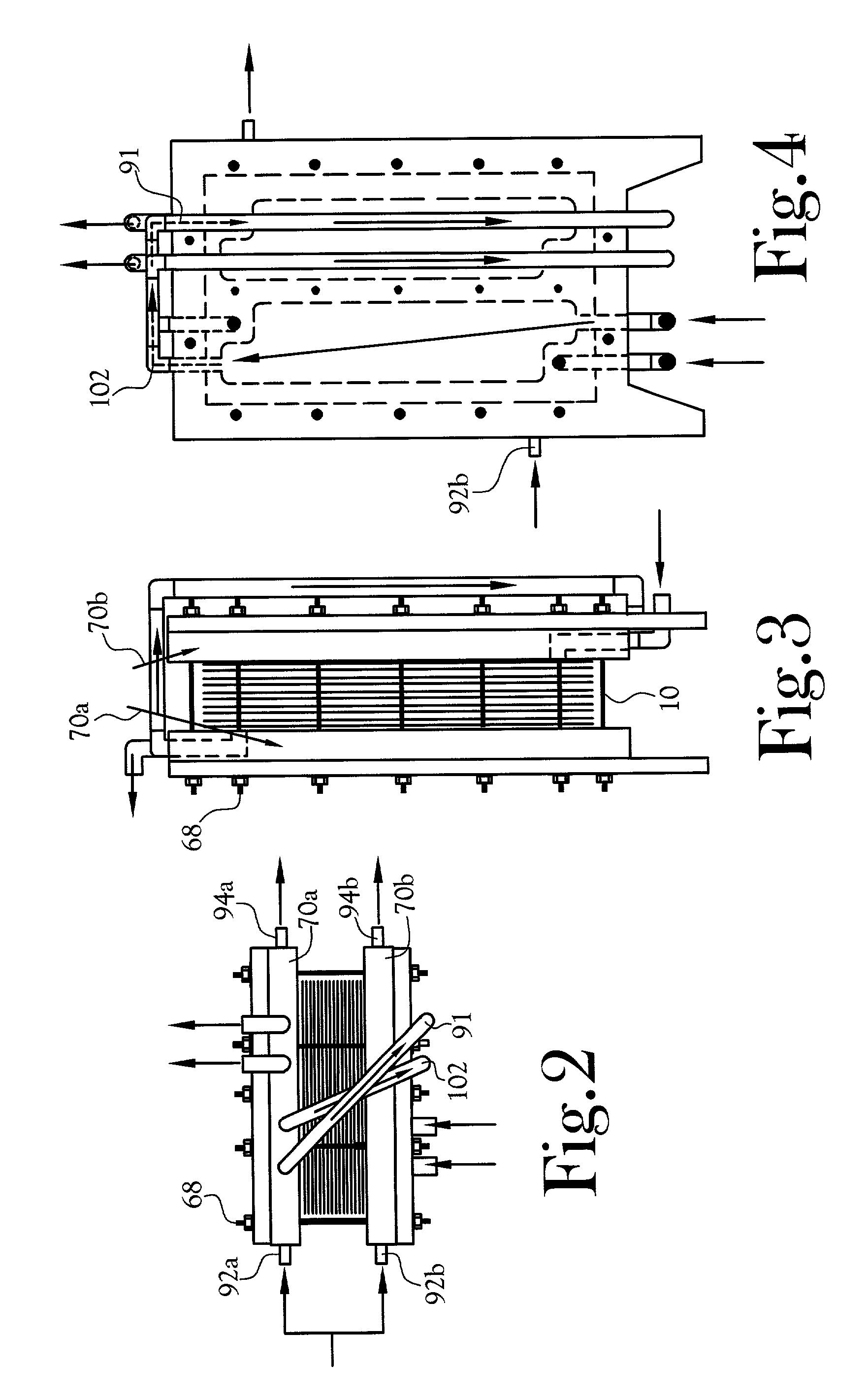

Multi-path split cell spacer and electrodialysis stack design

a split cell spacer and electrodialysis technology, applied in the direction of liquid/fluent solid measurement, fluid pressure measurement, peptide, etc., can solve the problems of inability to consistently and economically produce a cleansed fluid of sufficient quality that can be continuously recycled, prohibiting cost-effective recycling for environmental compliance or beneficial reuse, and many of the systems purchased by many businesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

shows the production rate and typical % removal of NaCl for the current invention; those skilled in the art will recognize these values allow the invention to be economically competitive for a variety of feeds. Example 3 shows typical membrane area and energy requirements for desalination using traditional ED stack designs contrasted with the performance of the current invention. Those skilled in the art will recognize that the improved design of the current invention results in a stack requiring significantly less membrane area and that is significantly more energy efficient.

2 1. NaCl Feed Production Rate % NaCl Concentration (m.sup.3 / m.sup.2 day) Removal 1.65 g / L 5.74 91 16.5 g / L 1.50 99

[0064]

3 NaCl Feed Traditional % Concentration Designs** Split cell Reduction A. Membrane Area (m.sup.2) for 1 m.sup.3 / day Capacity* 1 g / L 0.3 0.17 42% 10 g / L 1.2 0.67 44% B. Energy Requirements (kw-hr / m.sup.3 product)* 1 g / L 1.2 0.26 78% 10 g / L 3.4 2.67 21% *For a product concentration of 500 ppm T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| electrically conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com