Stand pillar double dead head type sand casting die

A technology of sand casting and riser type, which is applied in the field of sand casting molds with double riser type of standing column, can solve the problems of increasing the cost of casting repair, affecting the quality of castings, poor heat dissipation conditions, etc., and achieves simple structure, unobstructed feeding channel, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

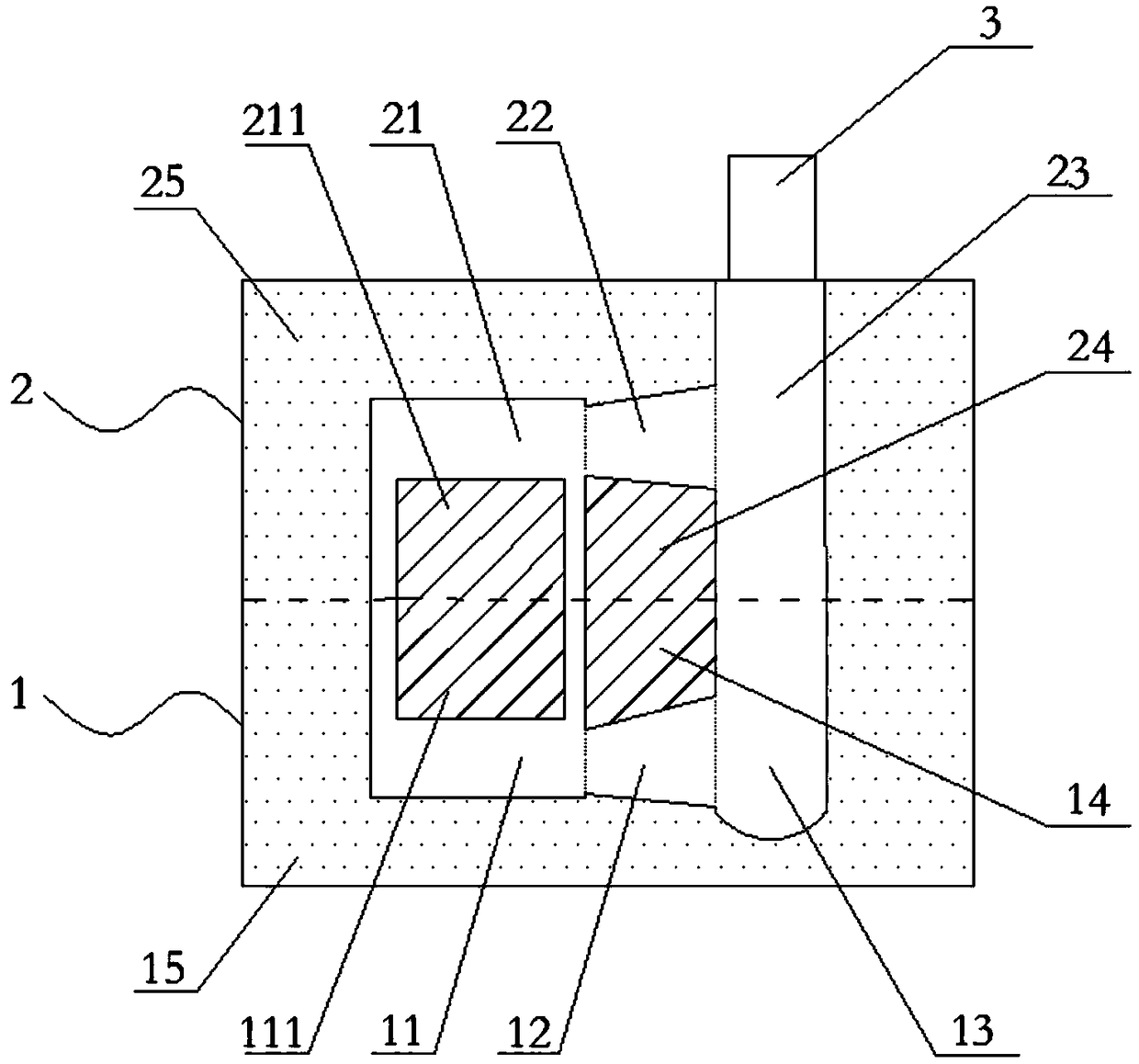

[0018] combined with figure 1 , the specific embodiment of the present invention is described as follows:

[0019] Such as figure 1 As shown in the figure, a sand casting mold with double risers for standing columns comprises a lower mold 1 and an upper mold 2, and the lower mold 1 is provided with a lower mold cavity 11, a lower riser neck mold cavity 12, and a lower standing column mold cavity 13. , the upper die 2 is provided with a casting upper cavity 21, an upper riser neck cavity 22, an upper station column cavity 23, a lower riser neck cavity 12, and an upper riser neck cavity 22 are all set in a circular table shape, and the lower The large end of the riser neck cavity 12 is vertically connected to the cavity 13 of the lower station column, and the small end is connected to the cavity 11 of the lower part of the casting; the large end of the cavity 22 of the upper riser neck is vertically connected to the cavity 23 of the upper column On, the small end is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com