Temperature monitoring system of concrete-filled steel tube arch bridge

A technology of concrete filled steel tube and monitoring system, applied in arch bridges, bridges, bridge forms, etc., can solve problems such as difficulty in detecting internal temperature, and achieve the effects of accurate monitoring of internal temperature of arch bridges, convenient and simple use, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

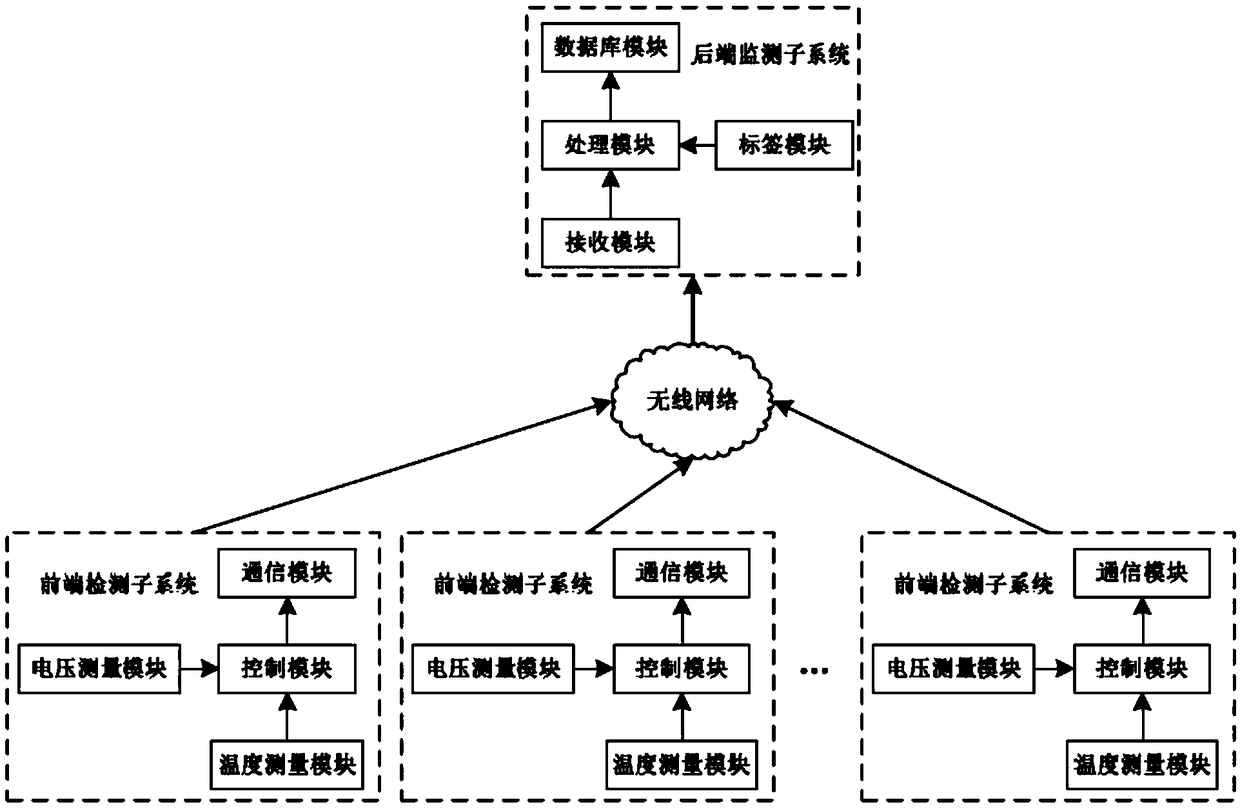

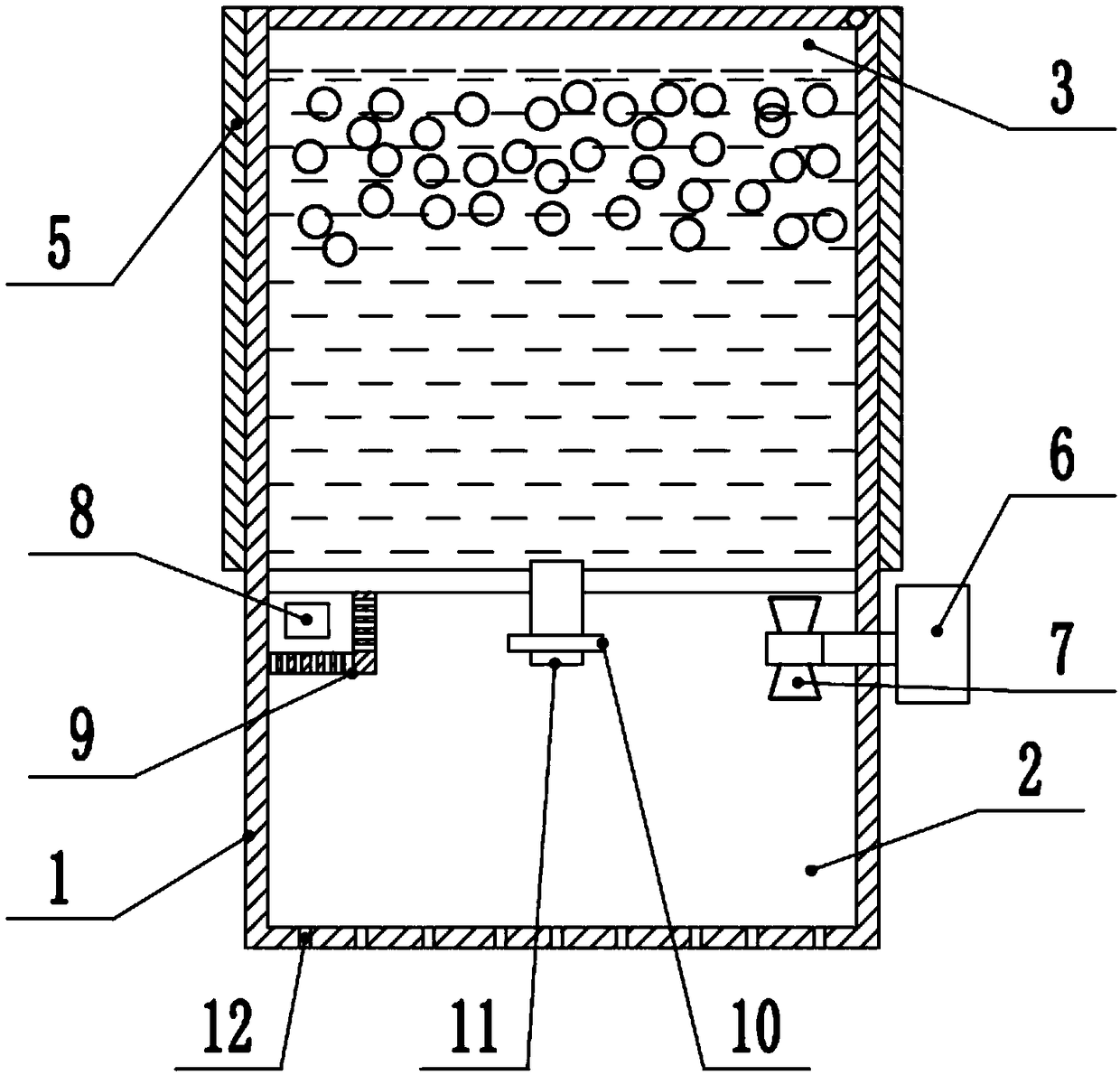

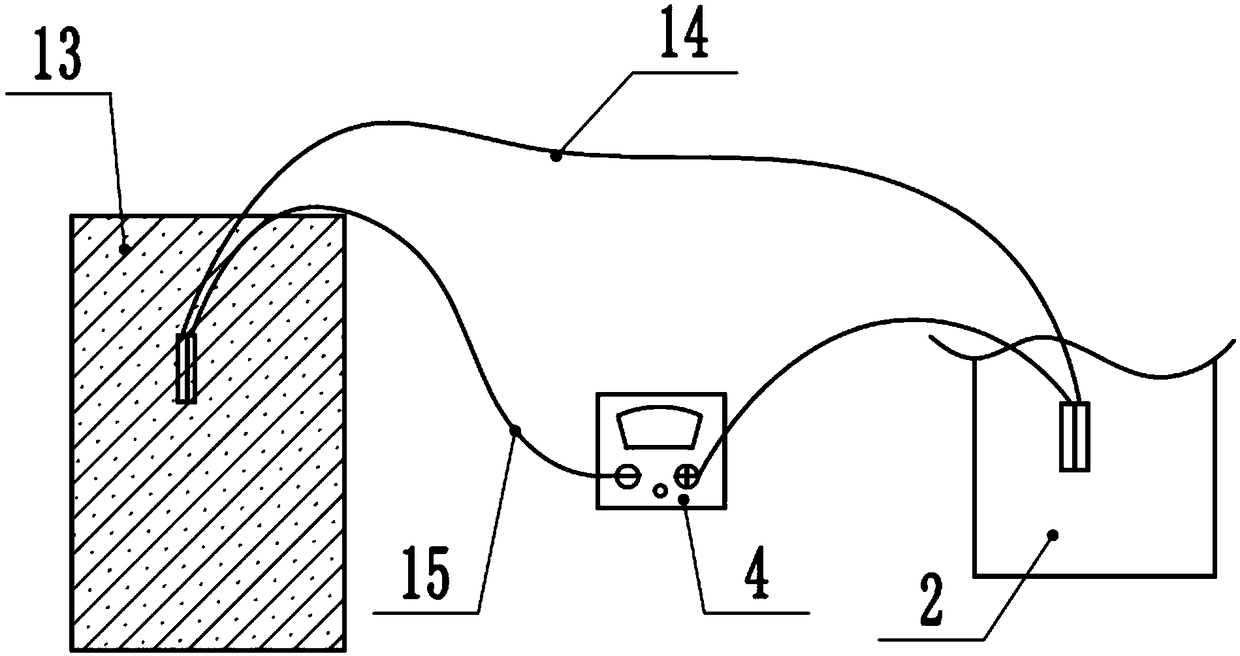

[0029] The temperature monitoring system of concrete filled steel tube arch bridge, such as figure 1 , figure 2 with image 3 Shown: including the front-end acquisition subsystem and the back-end monitoring subsystem, the front-end acquisition subsystem and the back-end monitoring subsystem communicate wirelessly, the temperature monitoring system also includes a heating box 1 located outside the arch bridge, the front-end acquisition subsystem includes the first metal Line 15, second metal wire 14, voltage measurement module 4, temperature measurement module 8, communication module and control module, voltage measurement module 4 can use existing millivolt meter, temperature measurement module 8 can use existing temperature sensing chip, communication The module can use the existing 3G communication chip, the control module can use the existing C8051F040 microcontroller, the back-end monitoring subsystem includes the receiving module, processing module, label module and dat...

Embodiment 2

[0042] The difference with Embodiment 1 is that, if Figure 4 Shown, in concrete 13 embed temperature sensing tube 18, temperature sensing tube 18 is steel and diameter is 3cm, and length is 10cm, and the size of steel temperature sensing tube 18 is less, and temperature sensing tube 18 can not be to concrete simultaneously. 13 produces adverse effects, the temperature sensing cylinder 18 is airtightly equipped with a piston plate 16, and the piston plate 16 separates the temperature sensing cylinder 18 into an induction chamber 17 and a compression chamber 23, the induction chamber 17 is filled with compressed air, and the compression chamber 23 Air-tight connection of the inner wall of the steel air duct 19, the diameter of the air duct 19 is 0.5cm, to avoid the diameter of the air duct 19 is too large and affect the characteristics of the concrete 13, the air duct 19 extends out of the end of the concrete 13 to air The airbag 20 is connected tightly, and the compression cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com