Surface anticorrosive antifouling coating using polydopamine as base layer as well as modification method and application of coating

An anti-fouling coating, polydopamine technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of surface coating bonding strength, anti-corrosion and anti-adhesion long-term application performance to be improved, etc. To achieve the effect of mild preparation conditions and simple preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of anti-corrosion and anti-fouling coating on stainless steel surface

[0042] First, the stainless steel surface is hydroxylated. Cut the stainless steel sheet (thickness 0.05mm) into a square of 1cm×1cm, and then wash it with distilled water, acetone and ethanol under ultrasonic conditions for 15min, and rinse it twice with distilled water. Immerse the cleaned stainless steel sheet in the newly prepared Piranha solution for 30 minutes at room temperature to make the surface rich in hydroxylation. Finally, wash with distilled water for 3 times and store in distilled water for later use.

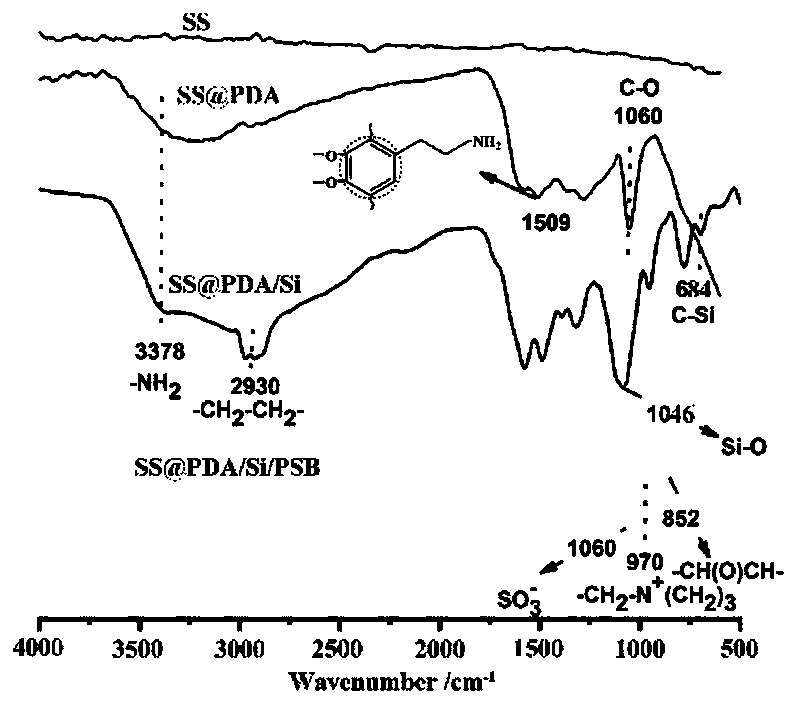

[0043] Dissolve 60 mg of dopamine hydrochloride in 30 mL of Tris-HCl solution to form a 2 mg / mL dopamine Tris-HCl buffer solution (pH=8.5), and stir at a constant speed for half an hour in the dark. Prepare a hydrolyzate of 30mg / mL APTES (the hydrolyzate is an aqueous ethanol solution containing 0.15wt% glycerol with an alcohol-water volume ratio of 1:6, and the pH value...

Embodiment 2~6

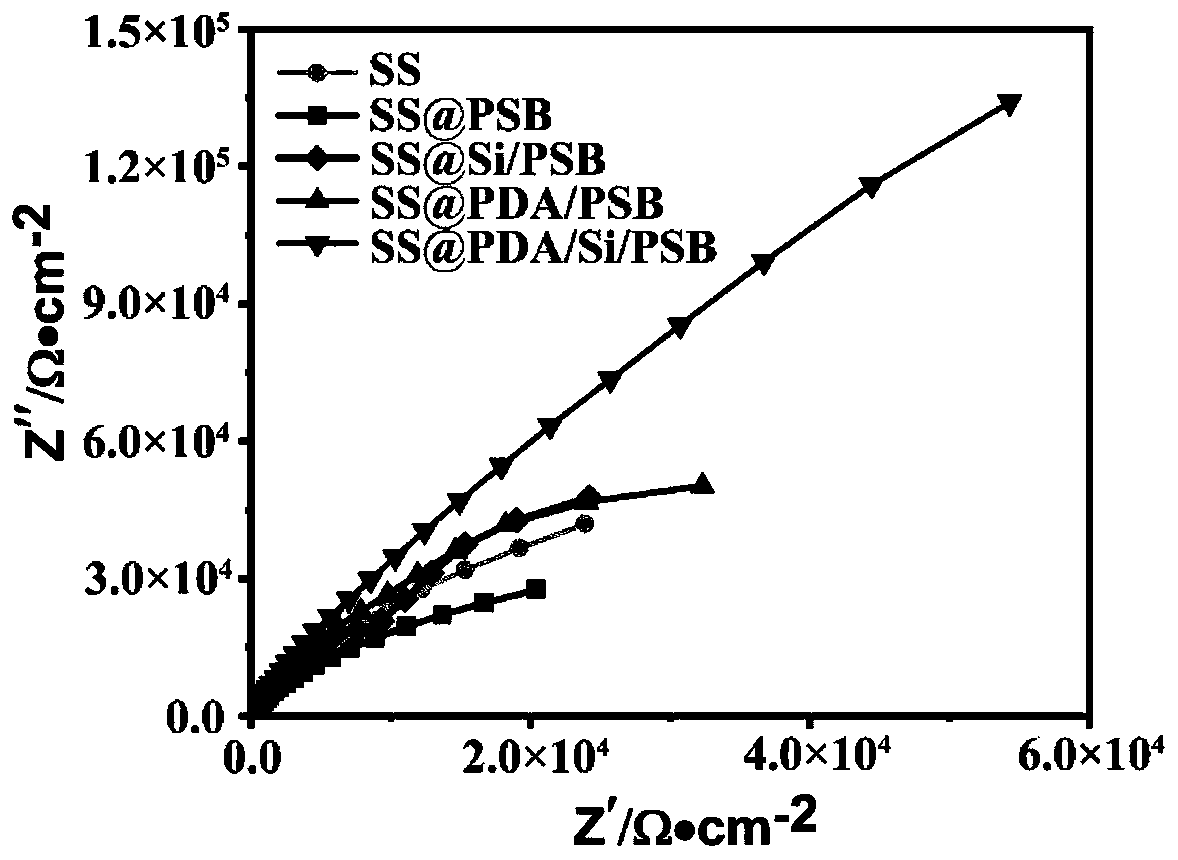

[0051] Press the method of embodiment 1, operate with embodiment 1, difference is to change the concentration of dopamine, temperature of reaction and time, obtain surface coating, measure the grafting density under different conditions, surface contact angle, protein adsorption amount, bacterial adhesion The amount of attachment and the change of anti-corrosion performance. As shown in table 2.

[0052] Table 2 Analysis of coating properties with different concentrations of dopamine solution, reaction temperature and reaction time

[0053]

Embodiment 7-12

[0055] According to the method of Example 1, the operation is the same as in Example 1, except that the concentration, reaction temperature and time of the APTES solution are changed to obtain different surface coatings, as shown in Table 3. The changes in graft density, surface contact angle, protein adsorption, bacterial adhesion and antiseptic performance under different conditions were measured. The results obtained are shown in Table 3.

[0056] Table 3 Analysis of coating properties with different APTES solution concentration, reaction temperature and reaction time

[0057]

[0058]

PUM

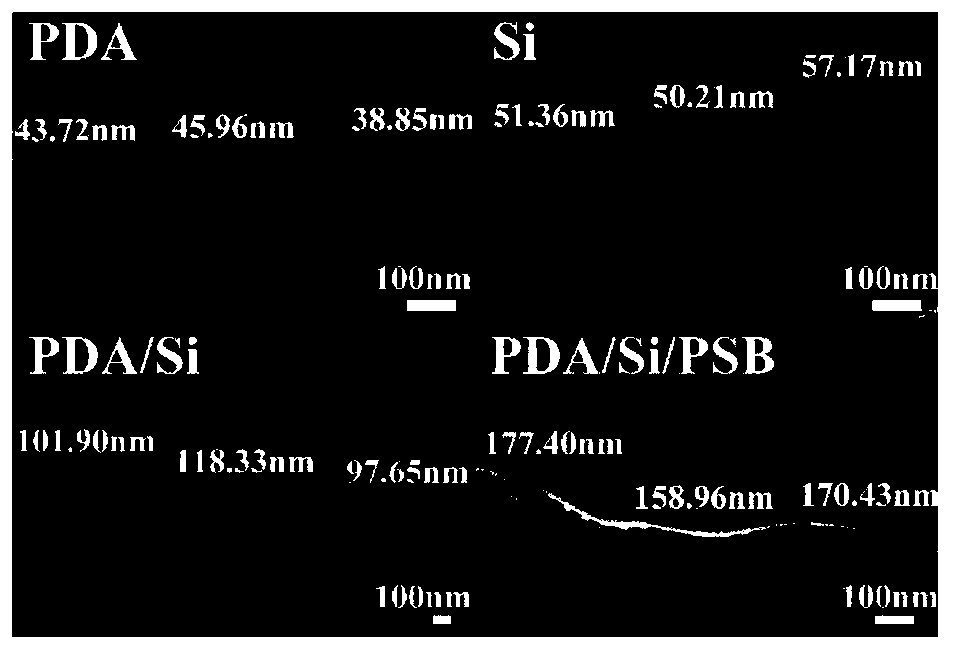

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com