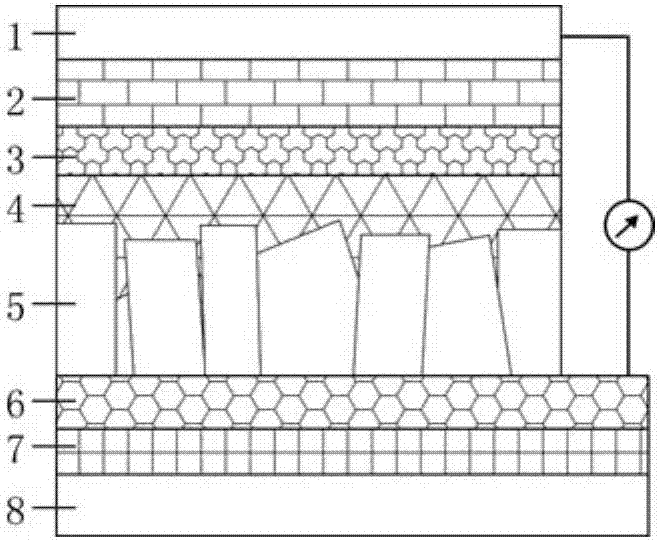

Thin-film solar cell based on inorganic planar hetero-junction and preparation method thereof

A thin-film solar cell and a technology for solar cells, which are applied in the field of solar cells and their preparation, can solve the problems of bound energy, difficulty in large-scale preparation, high-concentration defect states, etc., and achieve efficient electron selective transport channels and effective charge separation interfaces. , the effect of broad spectrum absorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

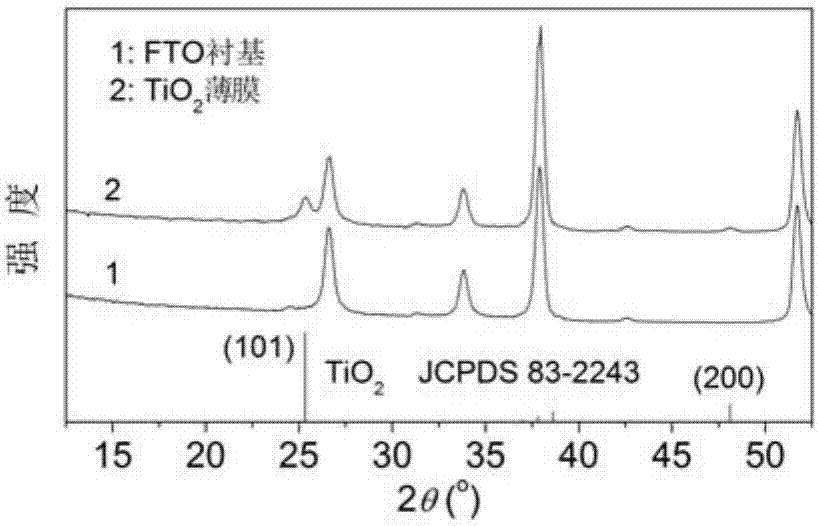

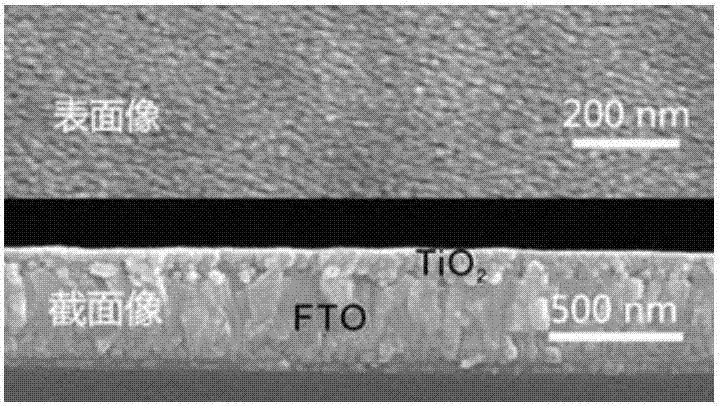

[0042] Example 1: TiO 2 Preparation of nanostructured dense films.

[0043] (1-1) Cleaning and etching of FTO conductive glass:

[0044] First, FTO conductive glass (FTO thickness 400nm, 14Ω / □) was ultrasonically cleaned with acetone, isopropanol, and ultrapure water for 5 minutes respectively to obtain a clean FTO conductive glass substrate. Secondly, use a mixture of concentrated HCl-water and Zn powder with a volume ratio of 1:1 to etch the FTO film on the clean FTO conductive glass to a size of 16×4mm 2 The thin strip is used as the anode of the solar cell; and then ultrasonicated by acetone, isopropanol, and ultrapure water for 5 minutes to obtain the etched FTO conductive glass substrate, which is dried and used for later use.

[0045] (1-2)TiO 2 Fabrication of Nanostructured Dense Films:

[0046] Mix absolute ethanol, n-butyl titanate, and glacial acetic acid at a volume ratio of 20:5:0.5 to form colorless and transparent TiO 2 Sol precursor. TiO 2 The sol precur...

Embodiment 2

[0049] Example 2: Sb 2 S 3 / TiO 2 Fabrication of Flat Heterojunction Thin Films.

[0050] (2-1) cleaning and etching of FTO conductive glass: with embodiment 1.

[0051] (2-2)TiO 2 Preparation of nanostructured dense film: same as Example 1.

[0052] (2—3)Sb 2 S 3 Preparation of reactant precursor solution:

[0053] SbCl at room temperature 3 Dissolve in N,N-dimethylformamide and stir for 0.5 hours to obtain clear SbCl with a concentration of 1.5mol / L 3 solution; then, in the resulting SbCl 3 Add thiourea to the solution, where SbCl 3 The molar ratio to thiourea was 1:1.8, and stirred at room temperature for 0.5 hours to obtain clear SbCl 3 and a mixture solution of thiourea; finally, add glycerol to this mixture solution, wherein the volume ratio of N,N-dimethylformamide and glycerol is 2.5:1, and stir for 10 minutes to obtain Sb 2 S 3 reactant precursors. The Sb 2 S 3 The reaction precursor solution is light yellow, uniform and transparent, and very stable. ...

Embodiment 3

[0058] Example 3: Sb 2 S 3 / TiO 2 Preparation of flat heterojunction thin film solar cells.

[0059] (3-1) cleaning and etching of FTO conductive glass: with embodiment 1.

[0060] (3-2)TiO 2 Preparation of nanostructured dense film: same as Example 1.

[0061] (3—3)Sb 2 S 3 / TiO 2 Preparation of flat heterojunction thin film: same as Example 2.

[0062] (3-4) Preparation of Spiro-MeOTAD chlorobenzene solution:

[0063] Add 80 mg of Spiro-MeOTAD powder into 1 mL of chlorobenzene, and stir at room temperature for 12 hours to obtain a light yellow Spiro-MeOTAD chlorobenzene solution. In the Spiro-MeOTAD chlorobenzene solution, add 17.5 μL of LiTFSI acetonitrile solution (520 mg / mL) and 29 μL of specific base pyridine (TBP) in sequence, and stir at room temperature for 6 hours to obtain light yellow transparent Spiro-MeOTAD, LiTFSI A mixture of chlorobenzene and TBP, wherein the molar ratio of Spiro-MeOTAD / LiTFSI / TBP is about 2 / 1 / 6.5.

[0064] (3-5)Sb 2 S 3 / TiO 2 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com