Rotor assembly for a vacuum pump and method for producing the same

A vacuum pump and rotor technology, which is applied to the components, pumps, and pump elements of a pumping device for elastic fluids, can solve problems such as reducing the joint force, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

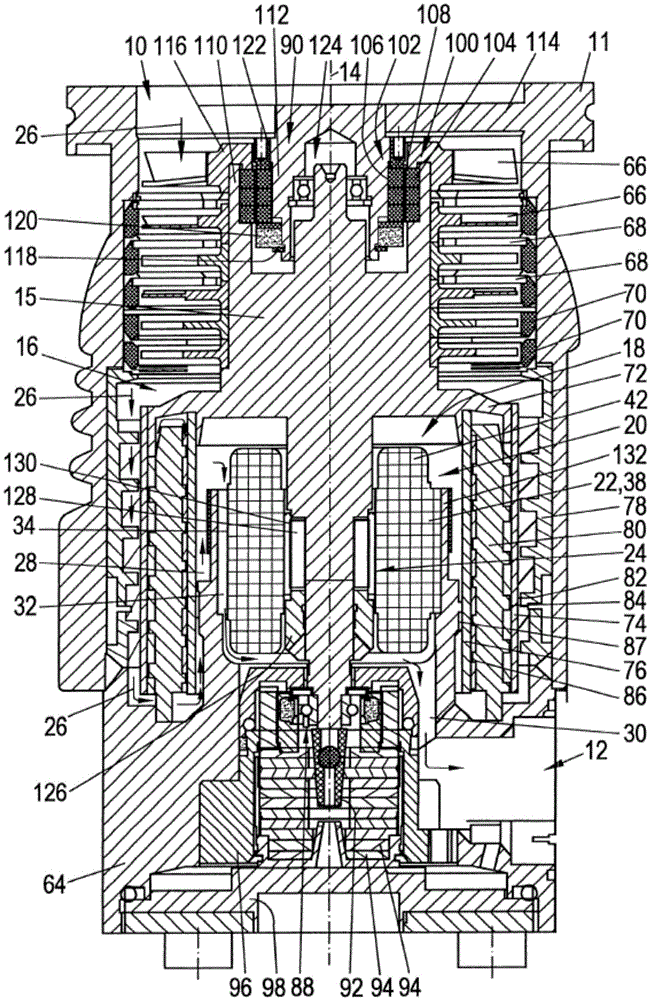

[0114] figure 1 The vacuum pump shown in includes a pump inlet 10 surrounded by an inlet flange 11 , a pump outlet 12 and a plurality of process gas pump steps for conveying process gas at the pump inlet 10 to the pump outlet 12 . The vacuum pump comprises a housing 64 and a rotor 16 arranged in the housing 64 , which has a rotor shaft 15 mounted rotatably about an axis of rotation 14 .

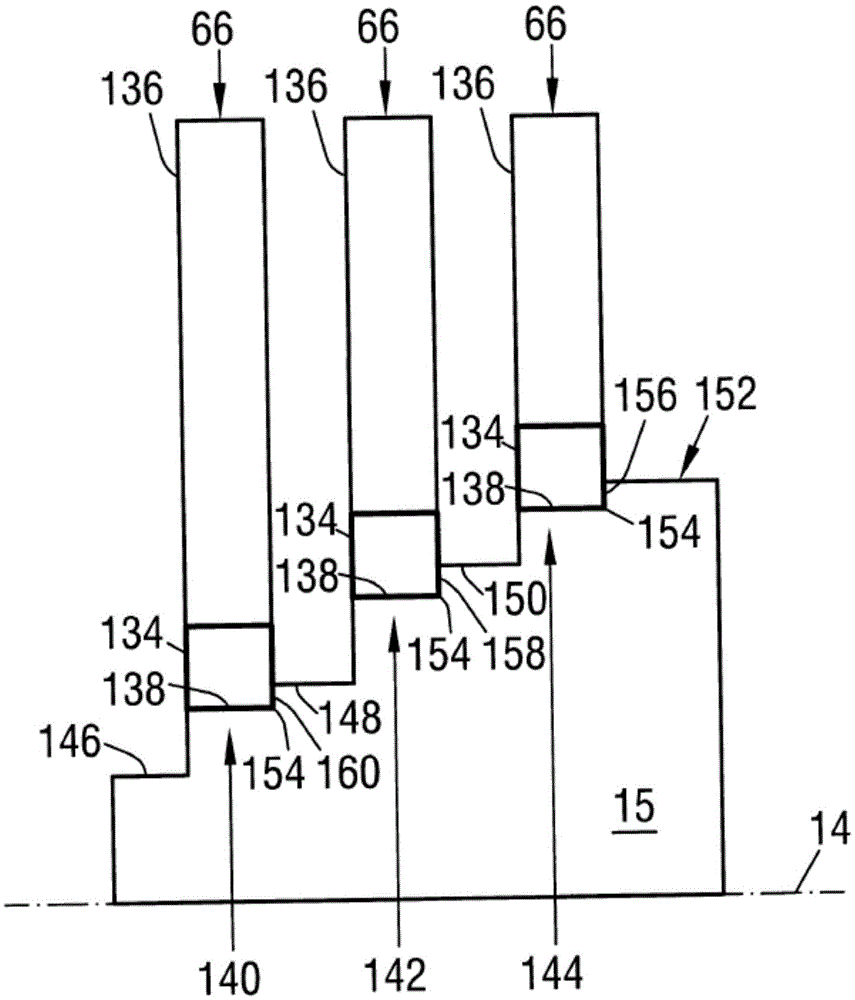

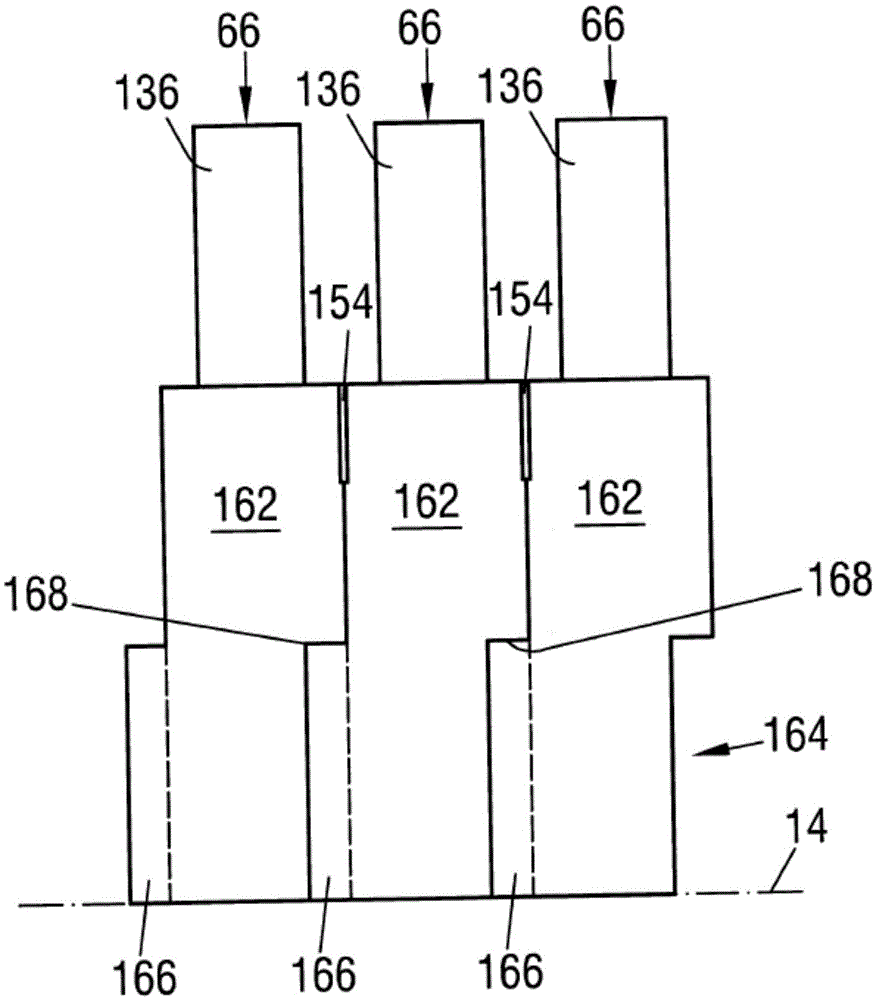

[0115]In the present exemplary embodiment, the pump is designed as a turbomolecular pump and comprises a plurality of turbomolecular pump stages connected in series with each other in a pumping manner (pumpwirksam), which have a plurality of radial pump stages fastened to the rotor shaft 15 . The rotor disk 66 and the stator disk 68 arranged in the middle of the rotor disk 66 and fixed in the housing 64, wherein the rotor disk 66 and the adjacent stator disk 68 respectively form a turbomolecular pump stage. The stator disks 68 are kept at the desired axial distance from one another by spacer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com