Holder for thermally contacting an electronic component and a cooling body

A technology for holding devices and electronic components, applied in circuit thermal devices, printed circuit components, electrical equipment structural components, etc., can solve problems such as inability to install thermal pads, forgetting to install thermal pads, and inability to compensate for offsets or angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

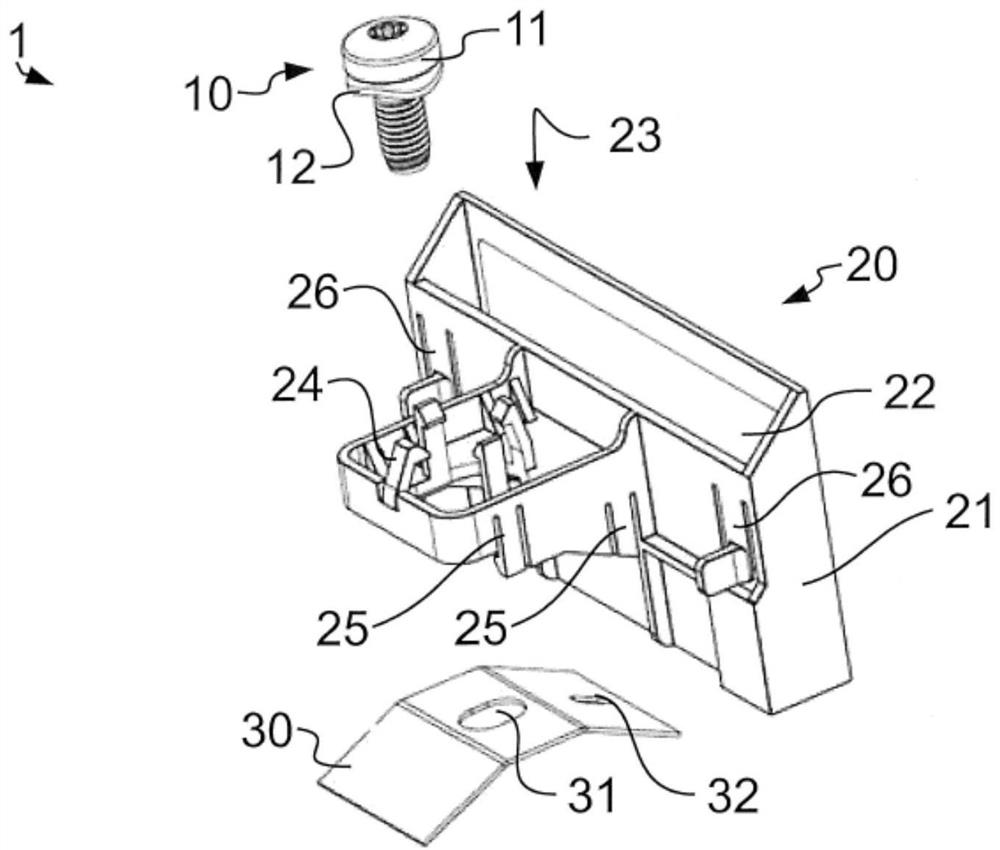

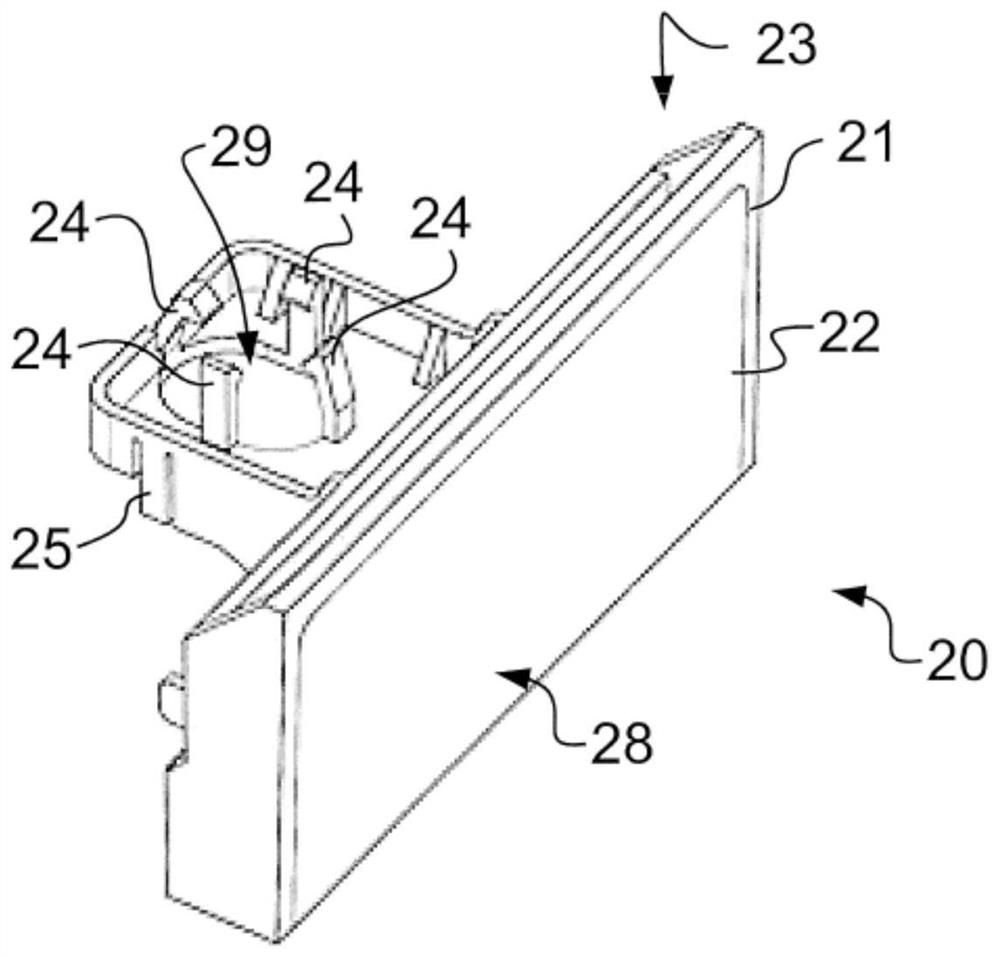

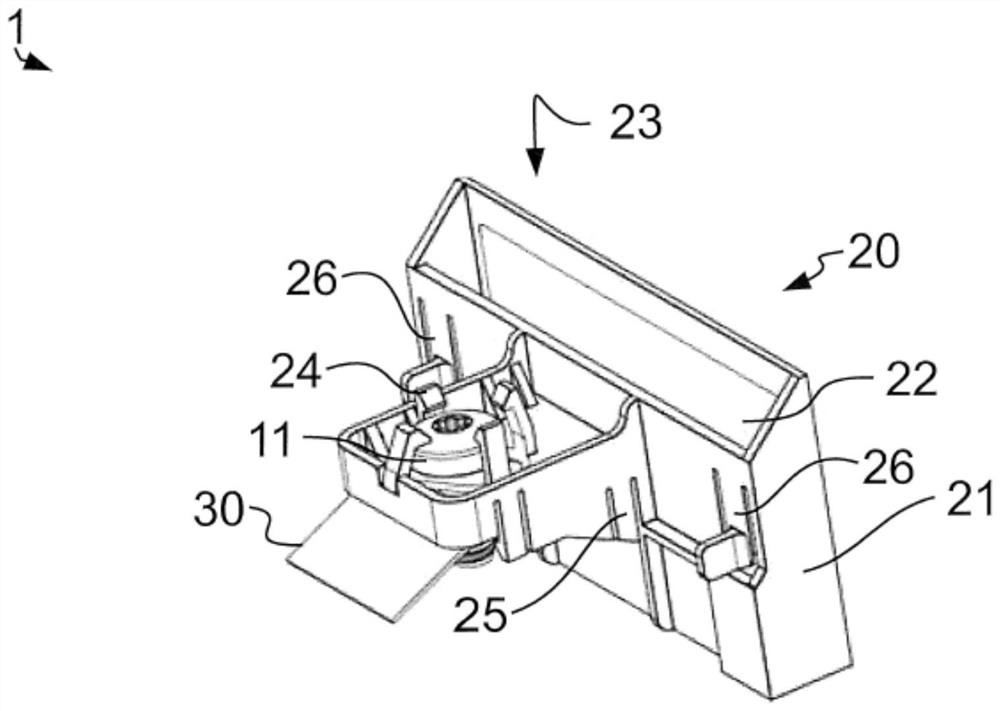

[0052] The accompanying drawings are illustrative schematic diagrams. The same reference numbers in the figures refer to the same functional and / or structural features.

[0053] figure 1 The holding device 1 is shown with three components, wherein the three components, namely the holding body 20 , the tensioning element 10 and the spring element 30 , are separated from one another. In addition, the holding body 20 is separately shown in a rotated state in figure 2 middle. The holding device 1 is shown in the state diagram in which its components are connected together in an anti-lost manner image 3 and Figure 4 middle. Figure 5 and Figure 6 shown in section Figure 1 to Figure 4 The different installed states of the holding device 1 are shown, so that the following description basically applies to all of the figures.

[0054] The retaining body 20 forms four first snap-in elements 24 on its engaging portion 21, these first snap-in elements are used for ringing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com