Feeding bag suitable for low-pressure casting of aluminum alloy thick large part

A technology of low-pressure casting and feeding bag, which is applied to the field of low-pressure casting of aluminum alloy thick and large parts, and can solve problems such as excessive porosity defects, shrinkage hole defects, and the vertical cylinder cannot be fed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

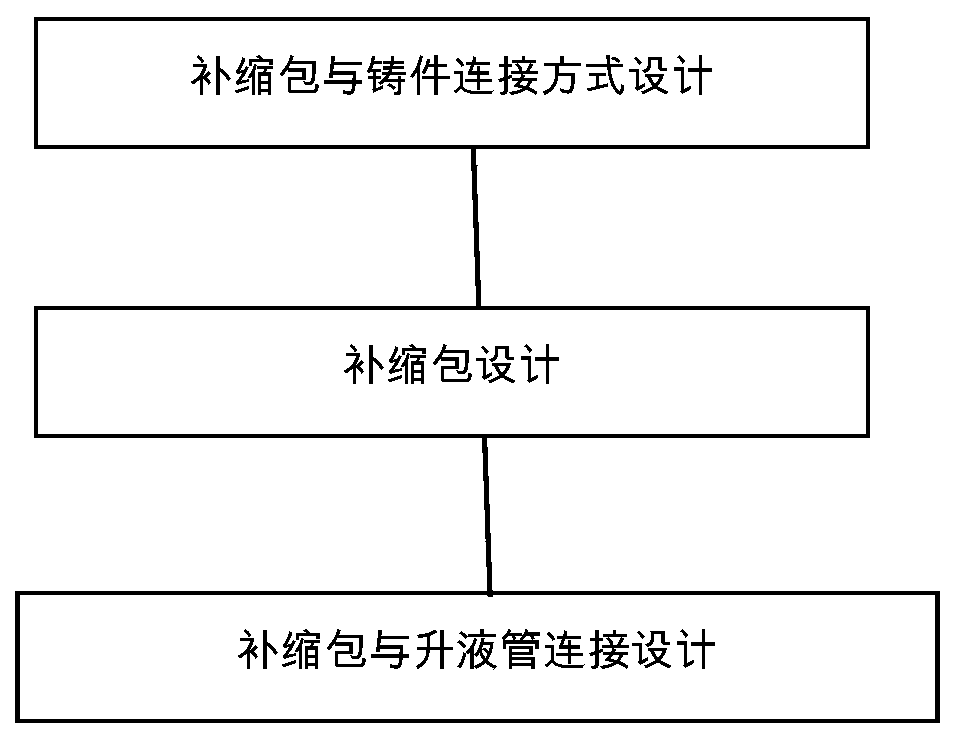

[0032] This embodiment provides a method for designing a feeding package for low-pressure casting of aluminum alloy thick and large castings. figure 1 It is a flow chart of casting gating system design provided by the embodiment of the present invention, combined below figure 1 Detailed description.

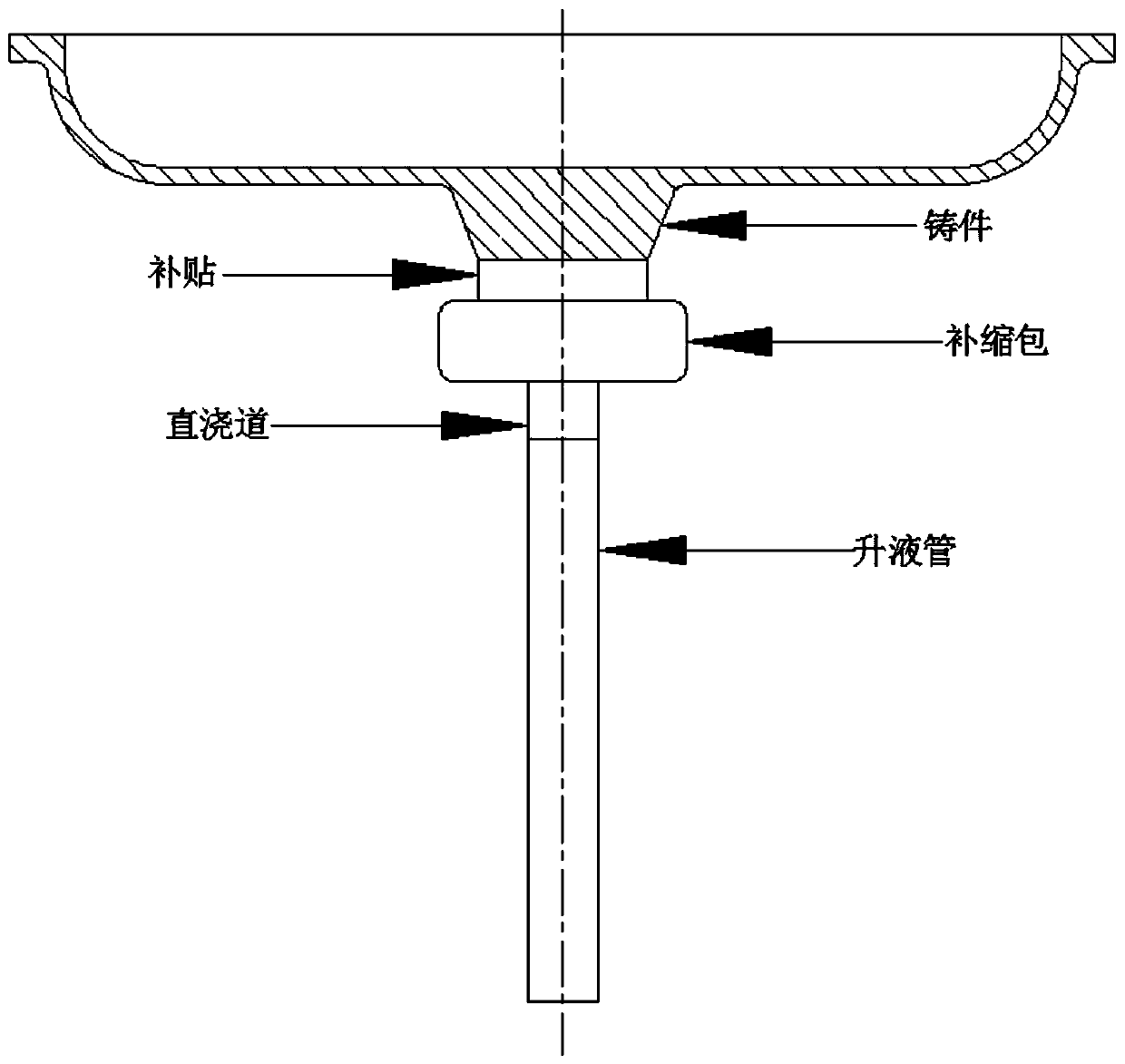

[0033] In step S1, the feeding bag and the casting are directly connected through subsidies, so that the temperature field in the feeding bag is much higher than that of the fed part, so that the thick part can be fully fed and the porosity defect is reduced;

[0034] Step S2, reasonably designing the feeding package;

[0035] Step S3, the feeding bag is connected to the riser through a sprue.

[0036] In the step S1, the feeding package is directly connected to the casting through a subsidy.

[0037] In the step S2, the packed package is determined according to the size of the part to be packed.

[0038] In the step S3, the size of the sprue is determined according to the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com