A Method for Reducing Microporosity in Cast Superalloy Test Bar

A micro-porosity technology for high-temperature alloys, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve problems such as unfavorable superalloy liquid feeding in time, failure to reflect mechanical properties, and excessive heat dissipation on the surface of test rods. , to achieve the effect of reducing micro-porosity defects, reducing non-metallic inclusions, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, taking the K424 alloy as an example, the method for reducing the microporosity in the cast superalloy test rod is carried out according to the following steps:

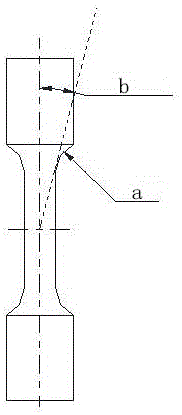

[0029] (1) Prepare the wax mold of the dumbbell-shaped superalloy test rod, increase the diameter of the tensile section of the wax mold of the dumbbell-shaped superalloy test rod, shorten the length of the stretching section, and make the angle of the feeding channel angle at 18°, such as figure 1 As shown, then prepare the dumbbell-shaped superalloy test rod shell;

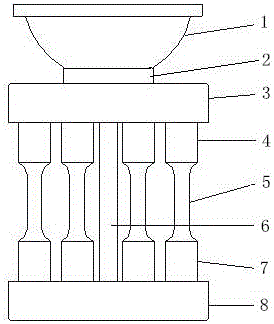

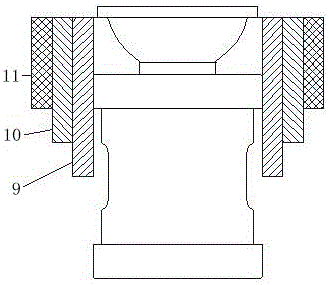

[0030] (2) Combined superalloy test bar pouring device, such as figure 2 As shown, the dumbbell-shaped superalloy test rod shell is installed between the upper disc and the lower disc, wherein the thickness of the upper disc is 20mm, and a sprue cup is arranged above the upper disc, and placed at the bottom of the sprue cup A ceramic foam filter screen with a porosity of 24PPI and a height of 15mm is wrapped with three layer...

Embodiment 2

[0035]In this embodiment, taking the K424 alloy as an example, the method for reducing the microporosity in the cast superalloy test rod is carried out according to the following steps:

[0036] (1) To prepare a wax mold of a dumbbell-shaped superalloy test rod, increase the diameter of the stretched section of the wax mold of the dumbbell-shaped superalloy test rod, shorten the length of the stretched section, and make the angle of the feeding channel angle 20°, such as figure 1 As shown, then prepare the dumbbell-shaped superalloy test rod shell;

[0037] (2) Combined superalloy test bar pouring device, such as figure 2 As shown, the dumbbell-shaped high-temperature alloy test rod shell is installed between the upper disc and the lower disc, wherein the thickness of the upper disc is 30mm, and a sprue cup is arranged above the upper disc, and placed at the bottom of the sprue cup A foam ceramic filter screen with a porosity of 22PPI and a height of 10mmmm is wrapped with t...

Embodiment 3

[0042] In this embodiment, taking the K424 alloy as an example, the method for reducing the microporosity in the cast superalloy test rod is carried out according to the following steps:

[0043] (1) Prepare the wax mold of the dumbbell-shaped superalloy test rod, increase the diameter of the tensile section of the wax mold of the dumbbell-shaped superalloy test rod, shorten the length of the tensile section, and make the angle of the feeding channel angle at 25°, such as figure 1 As shown, then prepare the dumbbell-shaped superalloy test rod shell;

[0044] (2) Combined superalloy test bar pouring device, such as figure 2 As shown, the dumbbell-shaped superalloy test rod shell is installed between the upper disc and the lower disc, wherein the thickness of the upper disc is 25mm, and a sprue cup is arranged above the upper disc, and placed at the bottom of the sprue cup A foam ceramic filter screen with a porosity of 20PPI and a height of 12mm is wrapped with three layers o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com