Improved low-pressure casting wheel mold

A low-pressure casting and mold technology, applied in the field of low-pressure casting molds for aluminum wheels, can solve problems such as low mechanical properties, low performance, and low air heat transfer capacity, and achieve the effects of improving mechanical properties, increasing solidification speed, and strengthening cooling strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

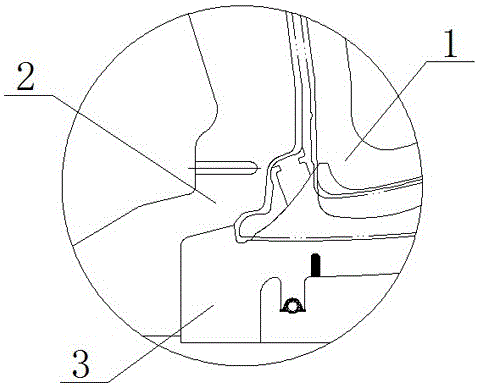

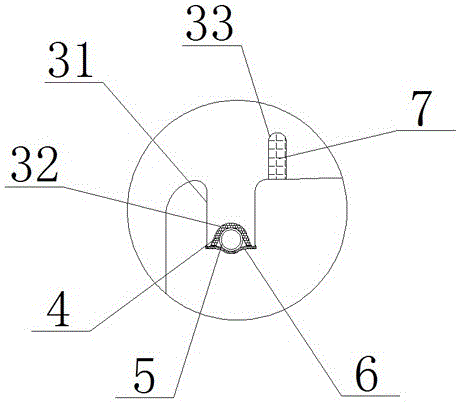

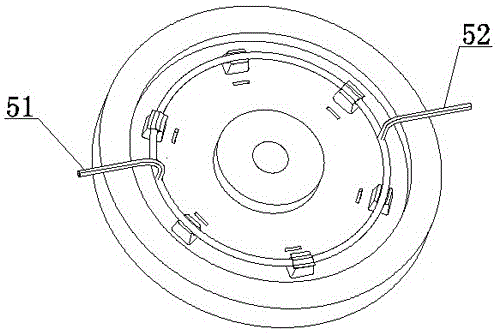

[0012] Figure 1-Figure 3 As shown, an improved low-pressure casting wheel mold includes a top mold 1, a side mold 2, and a bottom mold 3. The three together form a mold cavity, which ensures the smooth forming of the wheel casting; the root of the bottom mold 3 back cavity corresponds to A columnar boss 31 is set at the hot joint, the number of which is the same as the number of spokes, and it is used as a cooling source for the spot cold at the hot joint; a U-shaped through groove 32 is processed on the cylindrical boss 31, and a heat conducting gasket 4 is placed in the groove. You can choose red copper, graphite sheet, etc. with excellent thermal conductivity, with a thickness of 1-3mm; place the prepared annular water pipe 5 on the gasket in the groove, and the lower part of the water pipe should be higher than the end surface of the columnar boss, so as to ensure that the cover plate 6 can Tightly fix it in the groove, and achieve a good fit between the water pipe and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com