Method for casting upper bearing and lower bearing of compressor

A technology of a compressor and a manufacturing method, applied in the field of bearing manufacturing, can solve the problems of large shrinkage holes or shrinkage porosity, and the compressor ductile iron upper bearing and lower bearing cannot meet the requirements for use, and achieve the effect of eliminating shrinkage holes and shrinkage porosity.

Inactive Publication Date: 2014-11-19

肇庆精通机械有限公司

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The castings of the ductile iron upper bearing and lower bearing of the compressor produced by the vertical line without sand cores have large shrinkage cavities or shrinkage defects at the hot joint part 3, and the defect rate reaches 30%-70%, resulting in compressor failure. The upper and lower bearings of the ductile iron will be scrapped and cannot meet the requirements of use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0042] An air conditioner compressor upper bearing, the required material is ductile iron FCD600. After pouring through the above method, the product has no defects such as shrinkage cavity and shrinkage porosity inside the casting through X-ray flaw detection.

[0043] Other materials of the present invention also obtain the above effects.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

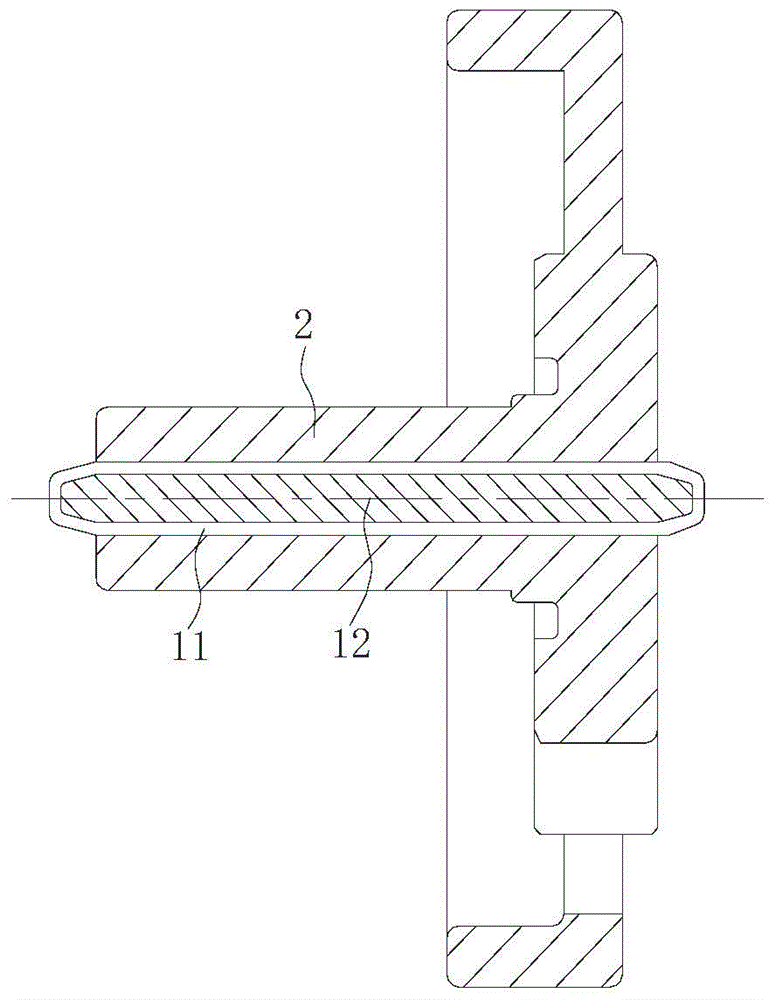

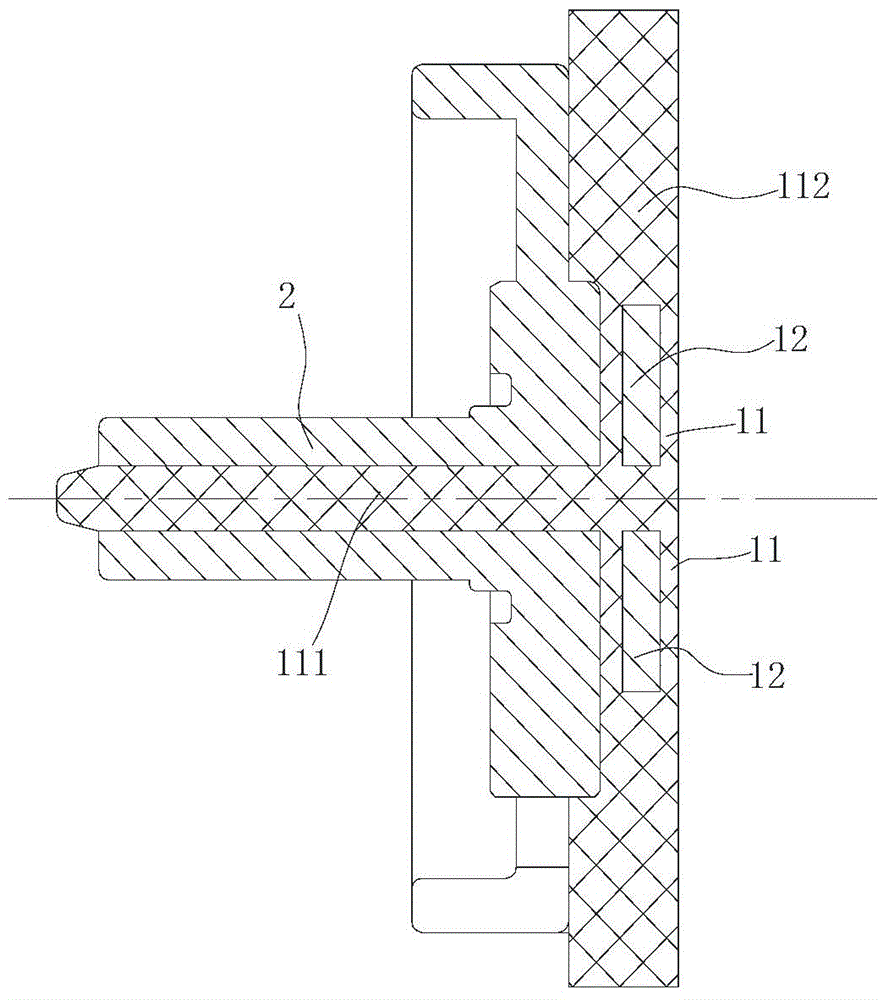

The invention discloses a method for manufacturing an upper bearing and a lower bearing of a compressor. The method comprises a step of forming a mixed sand core, wherein a metal core body is arranged in the mixed sand core, the mixed sand core is fixed in a sand mould cavity, and after being casted, the sand core falls off from the sand mould cavity to form a casting inner hole. The mixed sand core is structurally composed of the metal core body and a surface sand layer wrapping the outer portion of the metal core body. The method has the advantages of effectively eliminating shrinkage and shrinkage porosity of casting heat joint portions of the upper bearing and the lower bearing of the compressor, and enabling the casting quality to meet customer requirements.

Description

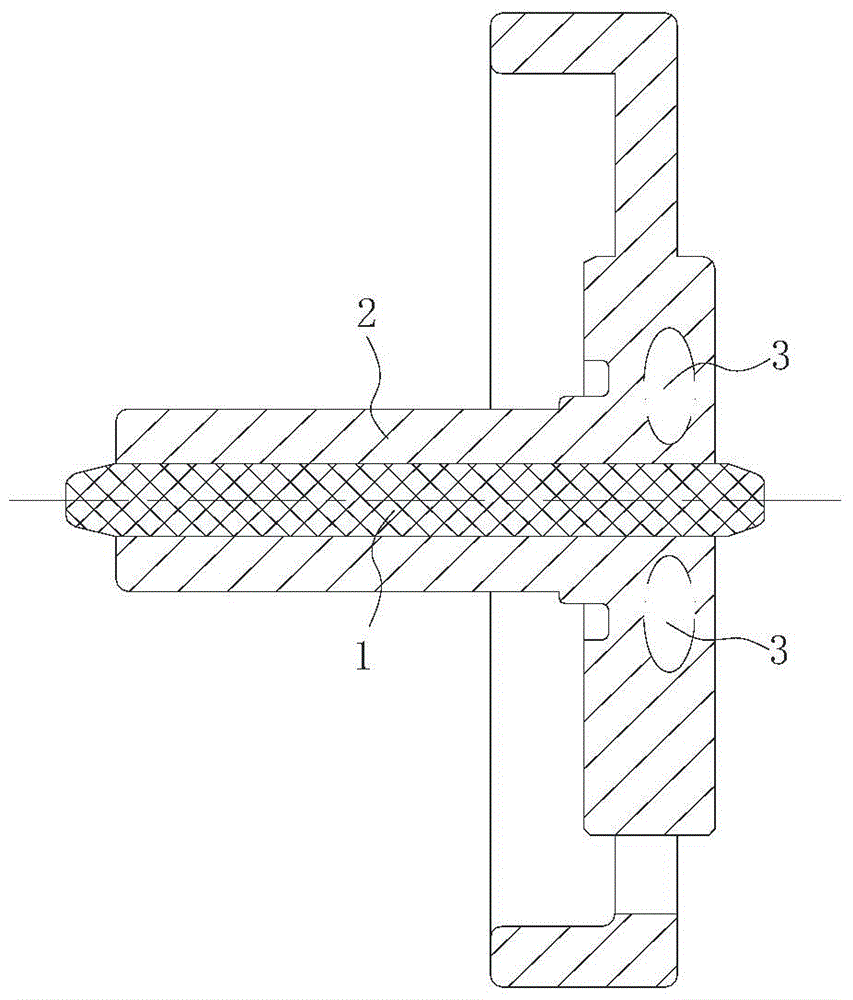

technical field [0001] The invention relates to the field of bearing manufacture, in particular to a method for manufacturing an upper bearing and a lower bearing of a compressor. Background technique [0002] The casting of the existing compressor ductile iron upper and lower bearings is produced with vertical lines. Such as figure 1 As shown, the casting body 2 of the upper bearing and the lower bearing uses a sand core at the center position, and the sand core needs to be lowered during the production process. Core setting methods include manual core setting and core setting machine automatic core setting. The castings of the ductile iron upper bearing and lower bearing of the compressor produced by the vertical line without sand cores have large shrinkage cavities or shrinkage defects at the hot joint part 3, and the defect rate reaches 30%-70%, resulting in compressor failure. The upper bearing and the lower bearing of the ductile iron will be scrapped and cannot mee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22C9/10B22C9/24

Inventor 贾平凡徐卫忠刘毅黄生荣

Owner 肇庆精通机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com