Crankcase ventilation pipeline heating joint

A crankcase ventilation and piping technology is applied in crankcase ventilation, fuel heat treatment devices, engine components, etc., to achieve the effects of easier implementation of control strategies, prevention of engine failure accidents, and long natural life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

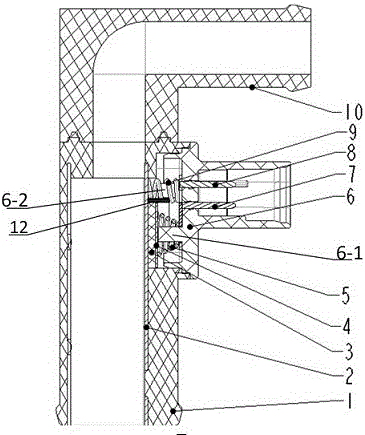

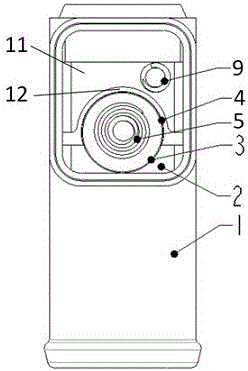

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

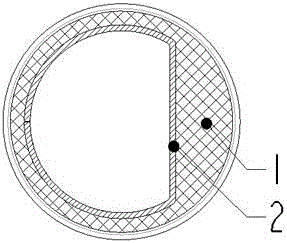

[0027] As attached figure 1 As shown, the crankcase ventilation pipe heating joint of the present invention includes a main casing 1, a secondary casing 10, a thermally conductive copper pipe 2, a plug-in cover 6 and a PTC heating mechanism. The main casing 1 and the secondary casing The inside of 10 forms a pipeline structure, and the connection between the main housing 1 and the secondary housing 10 forms a joint structure. The materials of the main housing 1, the secondary housing 10 and the plug-in cover 6 are all PA66+ GF30 (glass fiber reinforced nylon material) has good injection performance, and the relative angle between the main shell 1 and the secondary shell 10 is adjustable, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com