Method for producing diesel oil and bunker fuel blend component from coal tar

A technology for coal tar and fuel oil, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of low added value, environmental pollution, waste of resources, etc., to reduce hydrogen consumption, reduce investment, and improve operation. The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

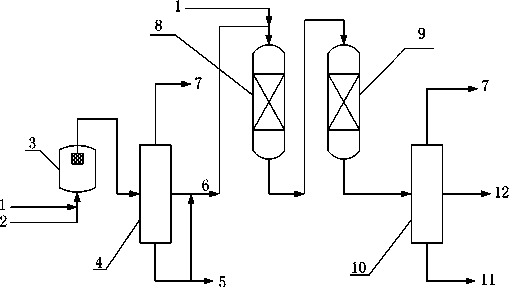

Method used

Image

Examples

Embodiment 1

[0028] The slurry bed hydrogenation catalyst added in the slurry bed reactor in this example is a Co-Mo type hydrogenation catalyst, and the fixed bed hydrofinishing catalyst in the fixed bed hydrofinishing reactor is a Ni-W type hydrogenation catalyst , the hydrocracking catalyst in the hydrocracking reactor is a Ni-W type hydrogenation catalyst, and the physical and chemical properties of the three catalysts are as follows in Table 1:

[0029] Table 1 Physicochemical properties of catalysts

[0030] Slurry bed hydrogenation catalyst Fixed bed hydrotreating catalyst Hydrocracking catalyst Specific surface area, m 2 / g 287 120 152 Pore volume, mL / g 0.85 0.37 0.39 Possible pore size, nm 11.8 7.2 7.0 carrier γ-Al 2 o 3 γ-Al 2 o 3 γ-Al 2 o 3 Cobalt oxide, % 4.7 / / Molybdenum oxide, % 15.2 / / Nickel oxide,% / 4.2 3.9 Tungsten oxide, % / 27.4 25.6

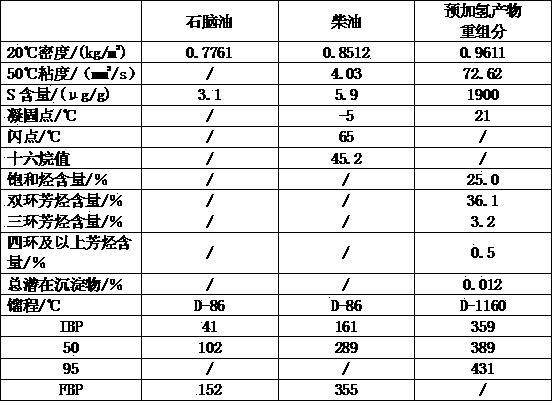

[0031] Coal tar property is as f...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that the slurry bed reactor is subjected to a pressure-lifting operation, and the feed amount of raw materials and the amount of ship fuel oil extracted are the same as those of Embodiment 1. The hydrocracking liquid product is distilled in a distillation pot to obtain naphtha fraction and diesel fraction.

[0044] The operating conditions of the slurry bed reactor in this embodiment are: the average reaction temperature is 230°C, the hydrogen partial pressure is 15.0MPa, and the space velocity is 0.5h -1 , The volume ratio of hydrogen to oil is 1500.

[0045] The operating conditions of the fixed bed hydrofining reactor are: the average reaction temperature is 380°C, the hydrogen partial pressure is 15.0MPa, and the space velocity is 0.5h -1 , The volume ratio of hydrogen to oil is 1500.

[0046] The operating conditions of the fixed bed hydrocracking reactor are: the average reaction temperature is 355°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com