Method of calculating hot spot temperature of micro-defect solar cell module

A solar cell module, hot spot temperature technology, applied in material defect testing, radiation pyrometry, measuring devices, etc., can solve problems such as cell mismatch, hot spot research, power consumption, etc., to reduce the probability of hot spots , the effect of improving economic benefits and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0033] The method for calculating the hot spot temperature of the micro-defect solar cell module of the present invention, such as figure 1 As shown, the details are as follows:

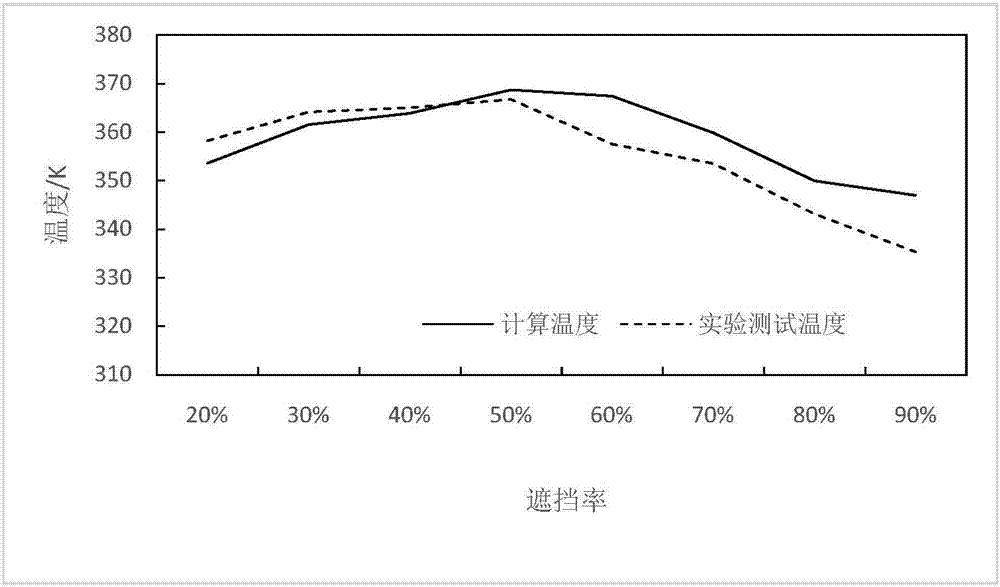

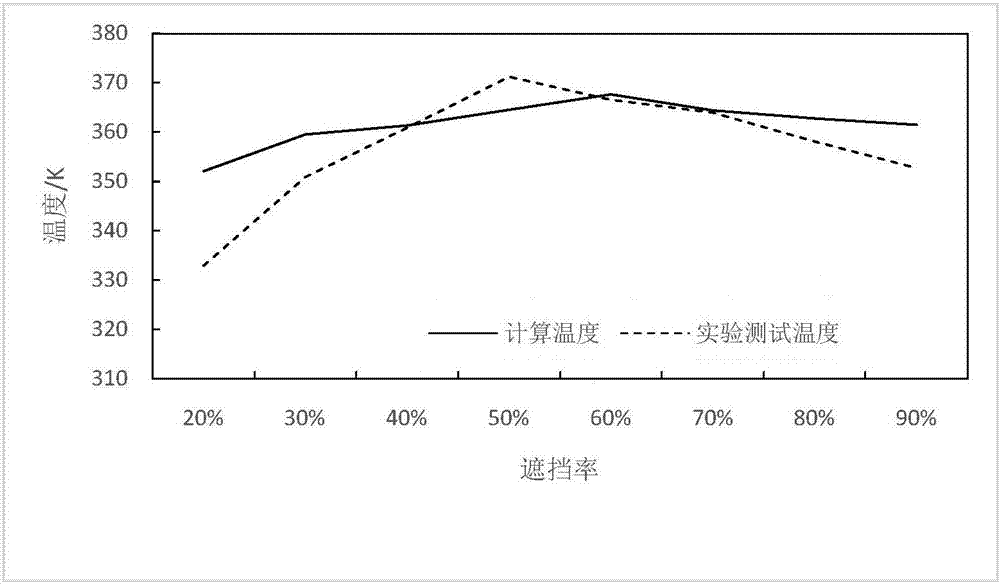

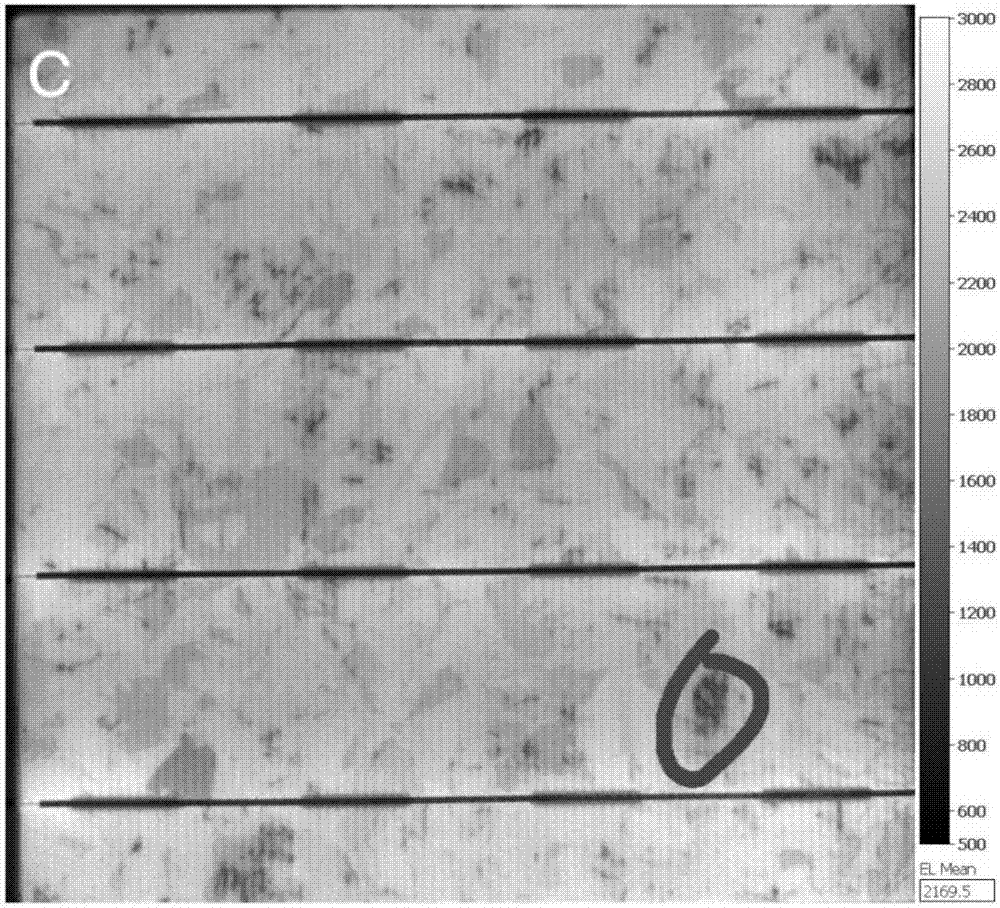

[0034] 1) Select one piece of cells with point defects, line defects, and surface defects, and then assemble them in modules respectively. One module contains one type of defect, and the rest of the modules are normal cells. The EL images of point, line, and surface defect cells are as follows: figure 2 , 3 , 4; apply a 12V reverse bias voltage at both ends of the tested cell, use an infrared thermal imager to measure the temperature, observe the temperature field formed on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com