Radiating structure for single chip package and system-in-package

A technology of system-level packaging and heat dissipation structure, which is applied in cooling/ventilation/heating transformation, instruments, sustainable buildings, etc., can solve problems such as cost increase, achieve the effect of increasing channels, reducing system hot spots, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

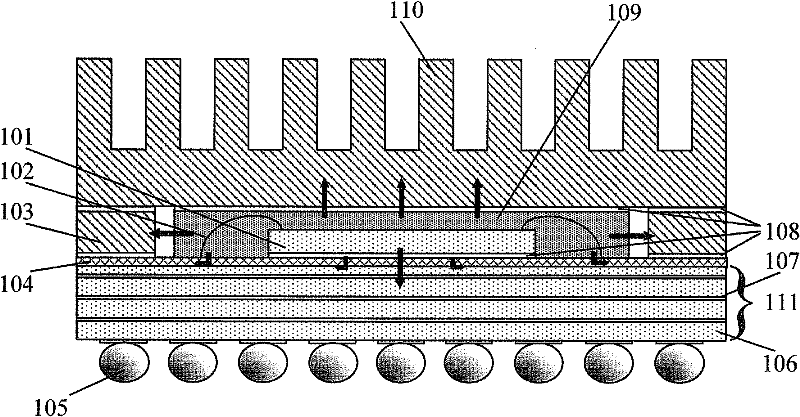

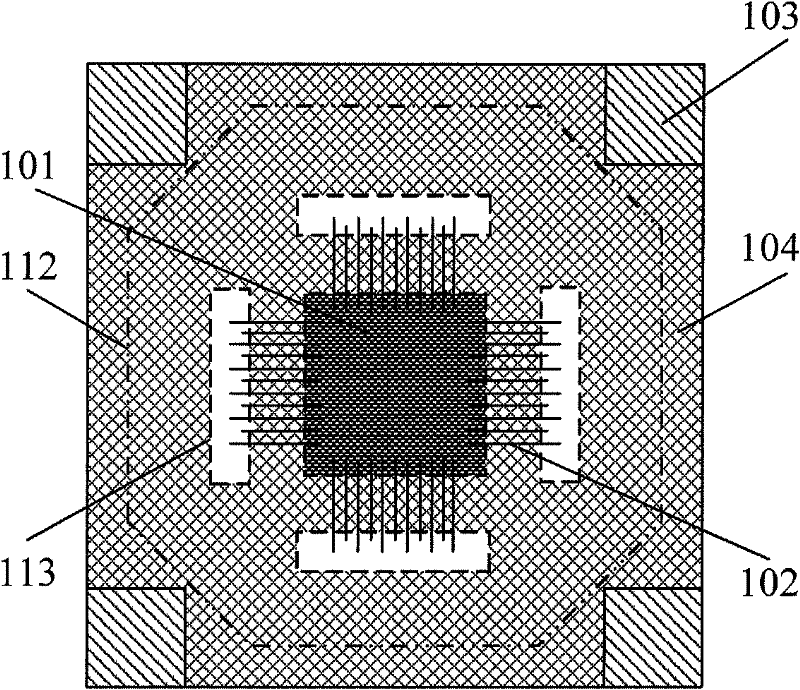

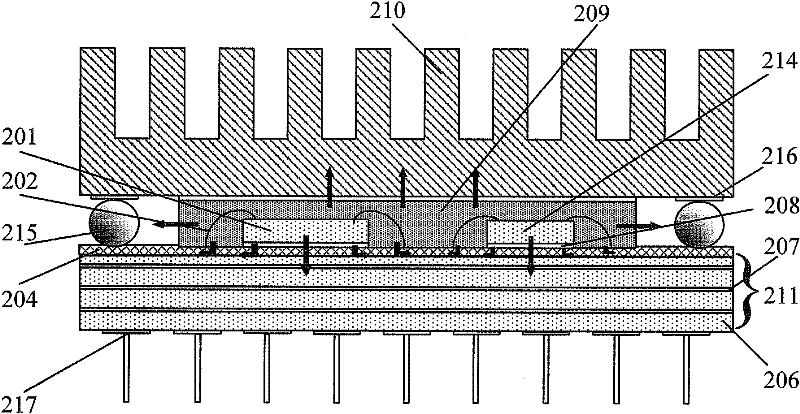

[0076] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0077] The present invention closely contacts the large-area heat sink structure directly below the bare chip, conducts more heat to the heat sink, and directly takes away the heat through the system air cooling, reducing system hot spots caused by conduction to the PCB through the substrate. Provides a third heat conduction direction for connecting heat sinks other than the top and surroundings for chip or module heat dissipation. In terms of mechanism, the heat conduction path, area and heat radiation are increased, and the heat dissipation efficiency is improved. It can also be flexibly combined with other heat dissipation methods to improve the overall heat dissipation effect.

[0078] Based on the above realization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com