Device for crystallizing and granulating struvite by strengthening gas-liquid fluidization

A technology of struvite and gas-liquid flow, which is applied in the field of gas-liquid fluidization strengthening struvite crystallization and granulation device, can solve the problems of substandard effluent water quality, poor settling performance, and reduced recovery efficiency, so as to ensure recovery efficiency and effluent water quality, improve the efficiency of crystal growth, and reduce the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

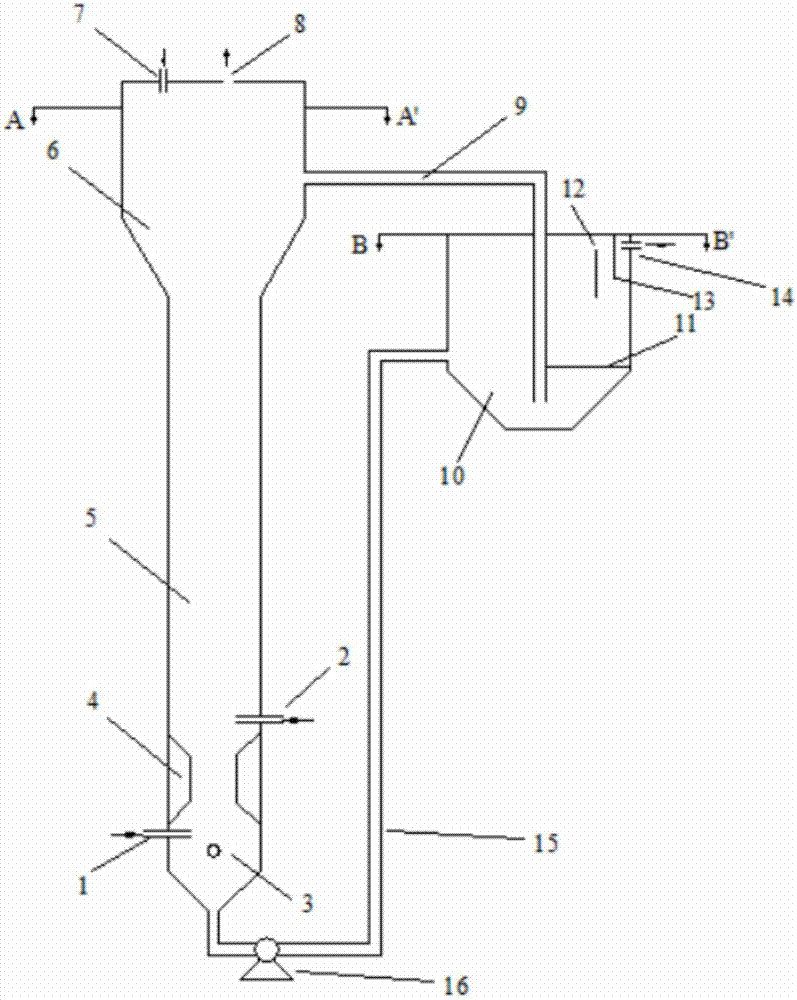

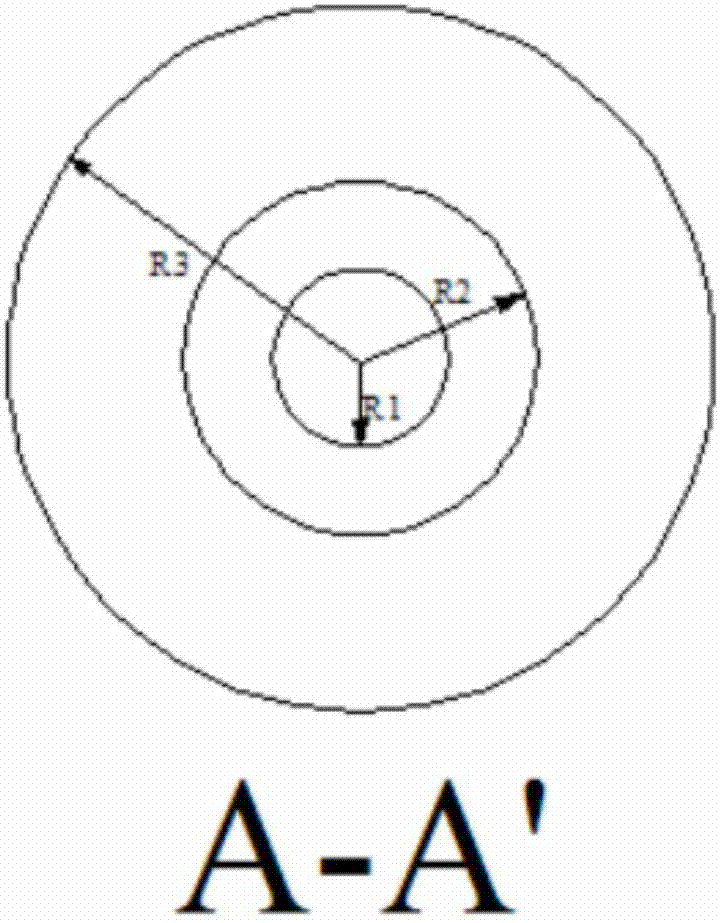

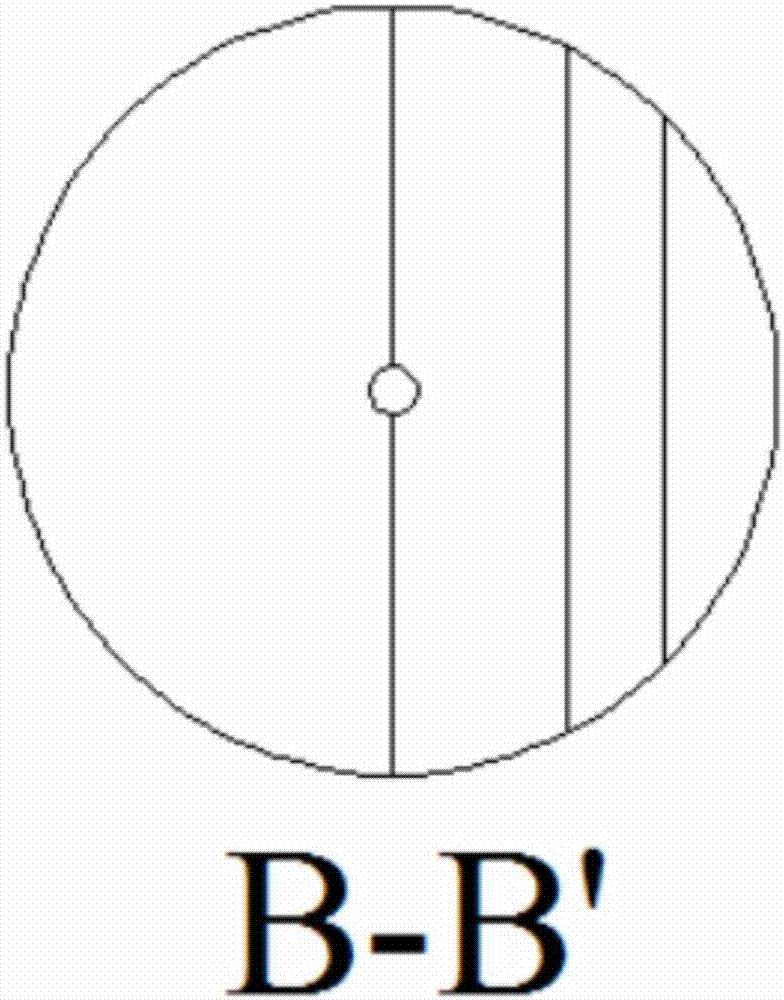

[0025] as attached figure 1 As shown, this embodiment includes a vertically arranged reactor main body and a settling area. The lower part of the reactor main body is a crystallization area, and the upper part is a fluidized layer. The upper part is wide and the lower part is narrow. The funnel-shaped first expanding pipe is connected; the crystallization area is provided with a nitrogen and phosphorus water inlet connected with the nitrogen and phosphorus water inlet pipe, a magnesium ion water inlet connected with the magnesium ion water inlet pipe, an aeration port connected with the air pump and a Venturi tube with high turbulence; the top of the fluidized layer is equipped with a pH adjustment pipe and an air outlet pipe, and the sedimentation area is set on the outer side of the reactor body and connected to the fluidized layer of the reactor body through a guide tube. The lower part of the sedimentation area is equipped with The horizontal partition occupying half of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com