Electrical ultrasonic atomization wet desulfurization spray nozzle and application thereof

A wet desulfurization and ultrasonic technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as poor atomization effect, achieve the effect of improving atomization effect, avoiding scouring, and solving blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

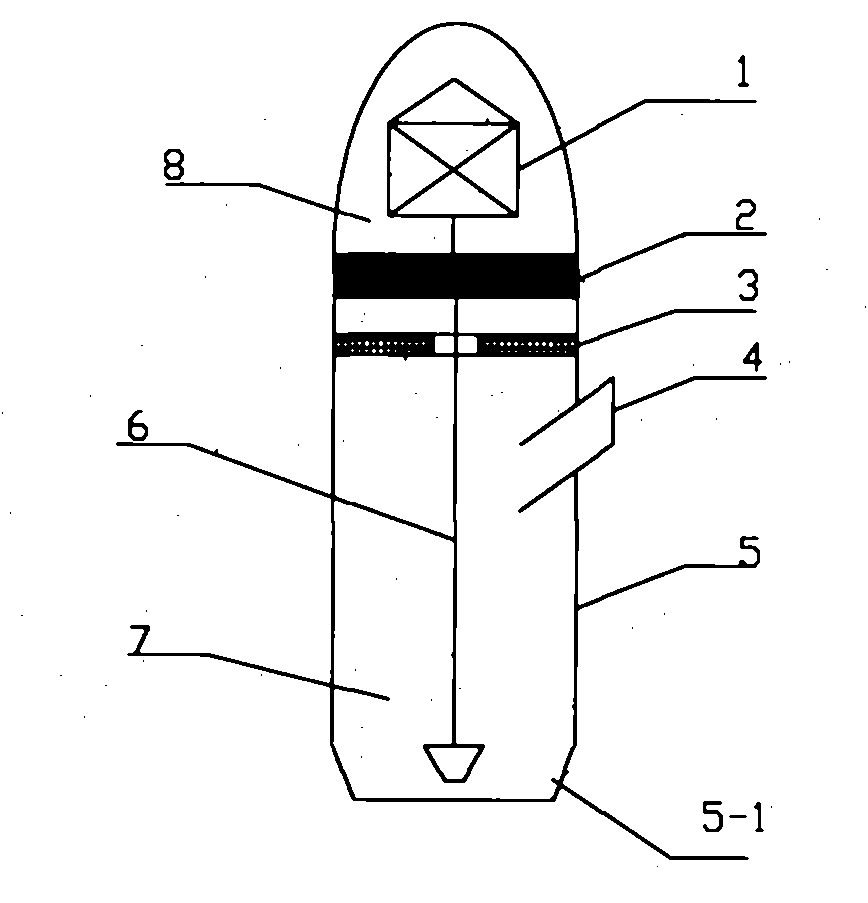

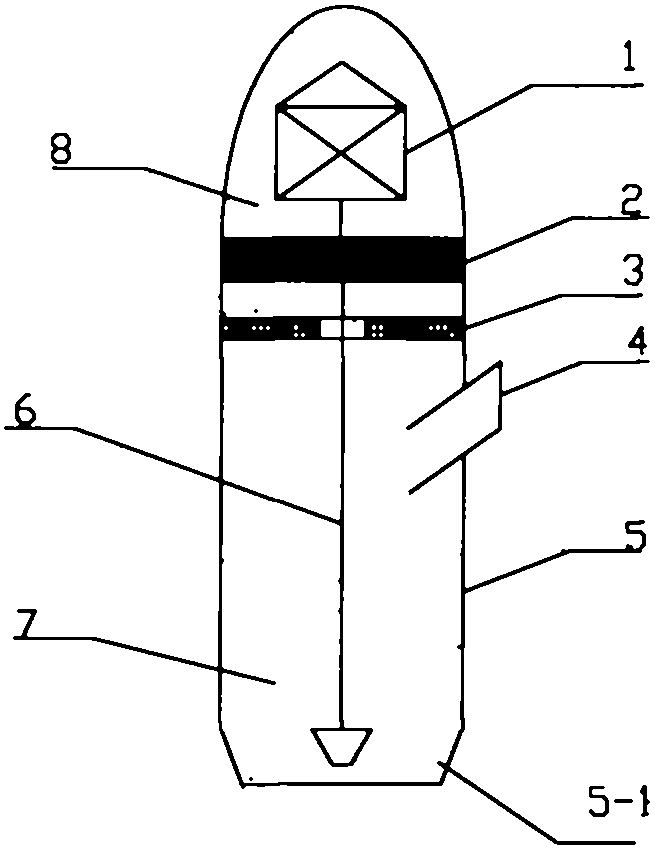

[0019] Such as figure 1 As shown, the electric ultrasonic atomizing wet desulfurization nozzle of the present invention includes an ultrasonic generating device placed in a housing 5, the ultrasonic generating device includes an ultrasonic generator 1, a transducer 2, and a horn 6, and the housing 5 is divided into an ultrasonic atomization chamber 7 and an ultrasonic generation chamber 8. The ultrasonic generator 1 is placed in the ultrasonic generation chamber 8, and the transducer 2 is arranged between the ultrasonic atomization chamber 7 and the ultrasonic generation chamber 8. The rod 6 passes through the transducer 2 and extends into the ultrasonic atomization chamber 7 , and a slurry inlet channel 4 is provided on the outer wall of the housing, and the slurry inlet channel 4 communicates with the ultrasonic atomization cavity 7 . The slurry is limestone slurry.

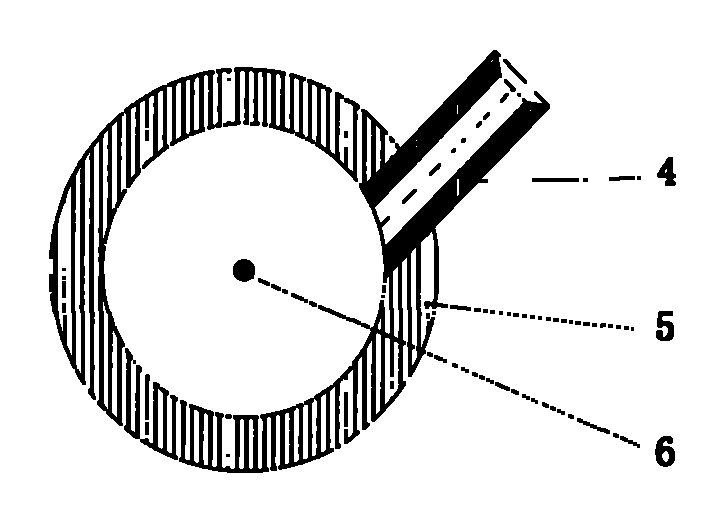

[0020] Such as figure 2 As shown, the slurry inlet channel 4 is arranged tangentially at 45° to the axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com