Gas distributor, gasifier and carbon-containing material gasification method

A technology of gas distributor and gasifier, which is applied in the field of gas distributor, gasifier and carbon-containing material gasification, can solve the problems of slow heat transfer, low gas velocity, material leakage and uneven flow of gasification agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

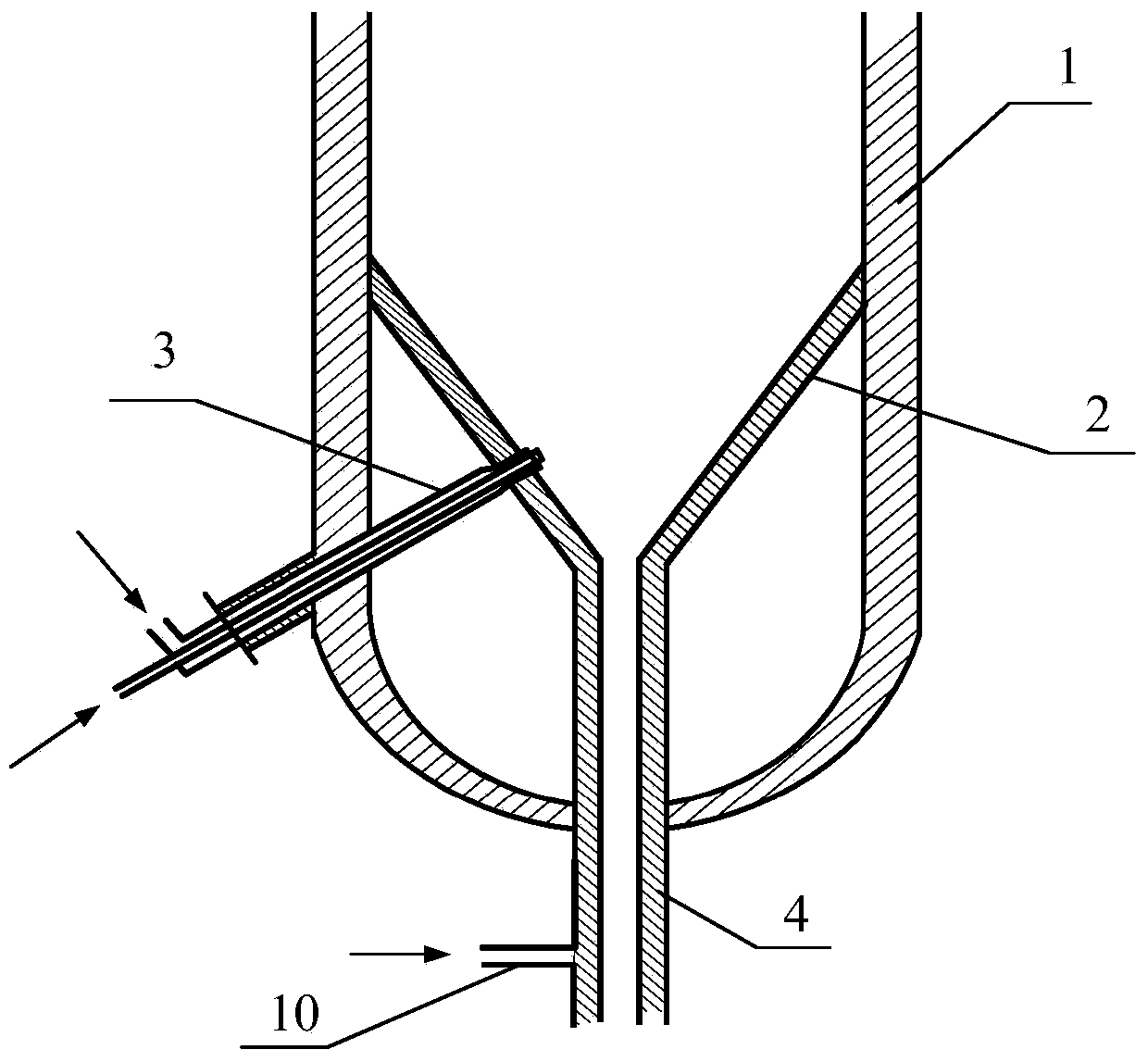

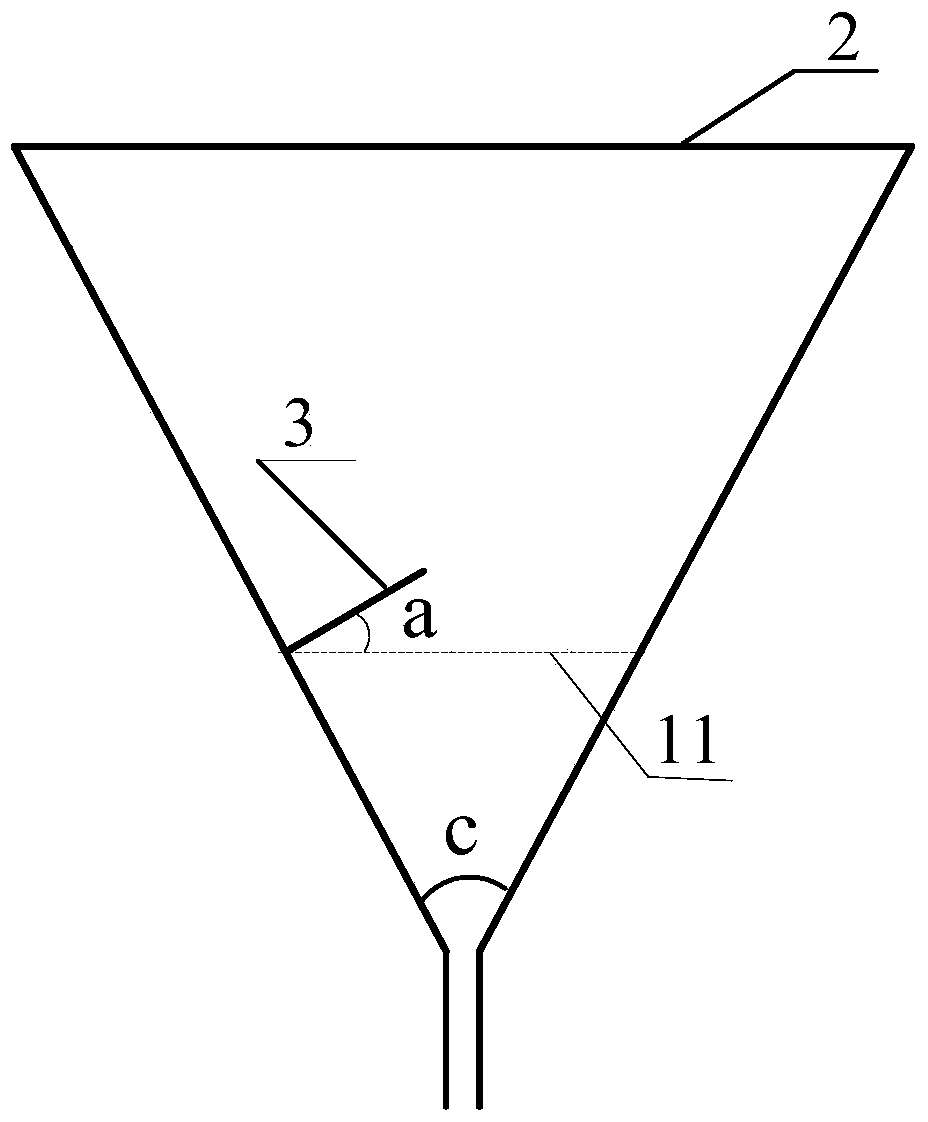

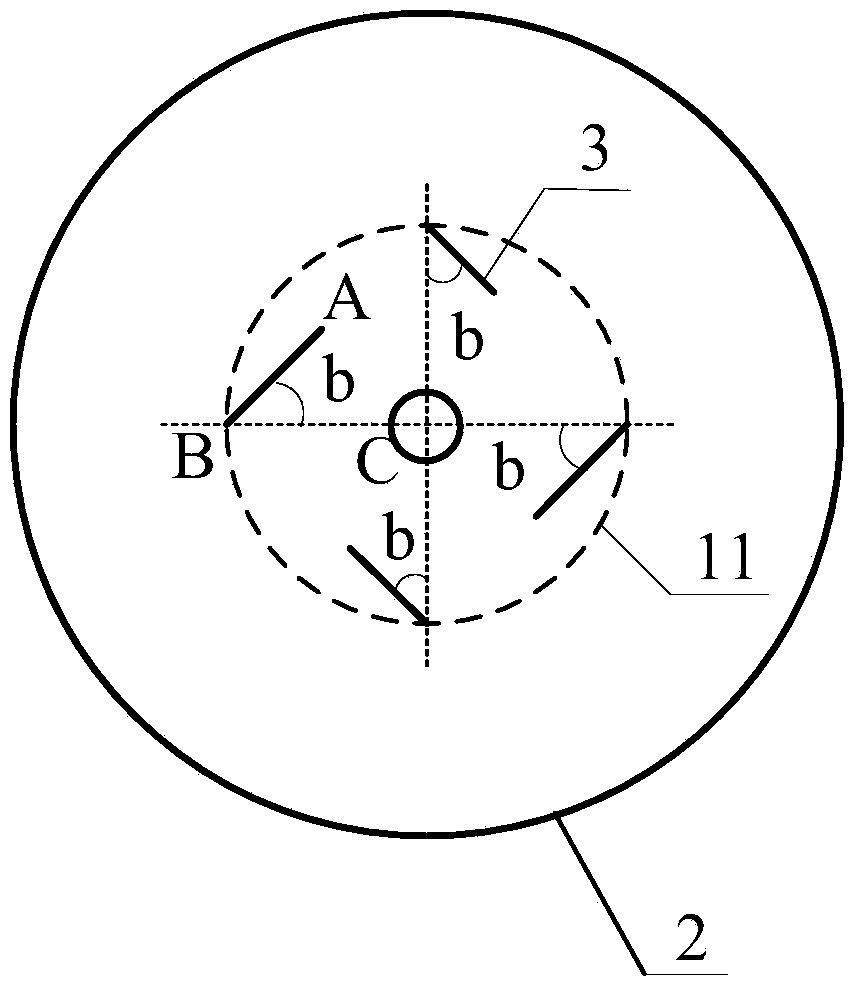

[0048] see figure 1 , figure 2 , image 3 and Figure 4, the embodiment of the present invention provides a gas distributor, including: a conical distribution plate 2 with a slag discharge port at the bottom, at least one nozzle 3 that runs through the conical distribution plate 2, and enters the cone through each nozzle 3 The gasification agent in the space surrounded by the shaped distribution plate 2 forms a vortex; wherein, each nozzle 3 includes: a central inner tube 8, at least one outer tube 7 sleeved on the central inner tube 8, a central inner tube 8 and An annular gap 9 is formed with at least one outer tube 7 .

[0049] When the above-mentioned gas distributor is used to gasify carbon-containing materials, the gasification agent enters the space surrounded by the conical distribution plate 2 through each nozzle 3 and forms a vortex, and the carbon-containing material enters the vortex formed by the gasification agent. , will flow with the gasification agent, an...

Embodiment 2

[0064] The embodiment of the present invention also provides a gasifier, including: a gasifier shell 1, a feed pipeline and a gas outlet pipeline respectively communicated with the gasifier shell 1, and the gasifier shell 1, Any gas distributor mentioned in the above technical solution. Specifically, please continue to figure 1 , the conical distribution plate 2 is installed through the gasifier shell 1, the slag discharge port of the conical distribution plate 2 is connected with the slagging pipe 4, and the slagging pipe 4 passes through the gasifier shell 1 downwards, and each nozzle The pipes 3 respectively pass through the preset holes on the gasifier shell 1 and the installation holes on the conical distribution plate 2 , and the gas outlets of each nozzle 3 protrude from the inner surface of the conical distribution plate 2 .

[0065] When the above-mentioned gasification furnace is used to gasify carbon-containing materials, the gasification agent enters the furnace s...

Embodiment 3

[0067] The embodiment of the present invention also provides a carbonaceous material gasification method, comprising:

[0068] 101. Pass the gasification agent into the furnace space above the conical distribution plate 2 in the gasification furnace through each nozzle 3, and the gasification agent entering the furnace space forms a vortex;

[0069] 102 Add carbonaceous materials into the gasification furnace from the feed pipeline, the carbonaceous materials flow with the vortex, and undergo gasification reaction with the gasification agent, the generated combustible gas is discharged out of the gasifier shell 1 through the gas outlet pipeline, and the generated Waste slag is discharged through the slag discharge port.

[0070]In more detail, when the carbonaceous material is gasified, the gasification agent enters the furnace space above the conical distribution plate 2 in the gasification furnace through each nozzle 3, and forms a vortex, and the carbonaceous material is di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com