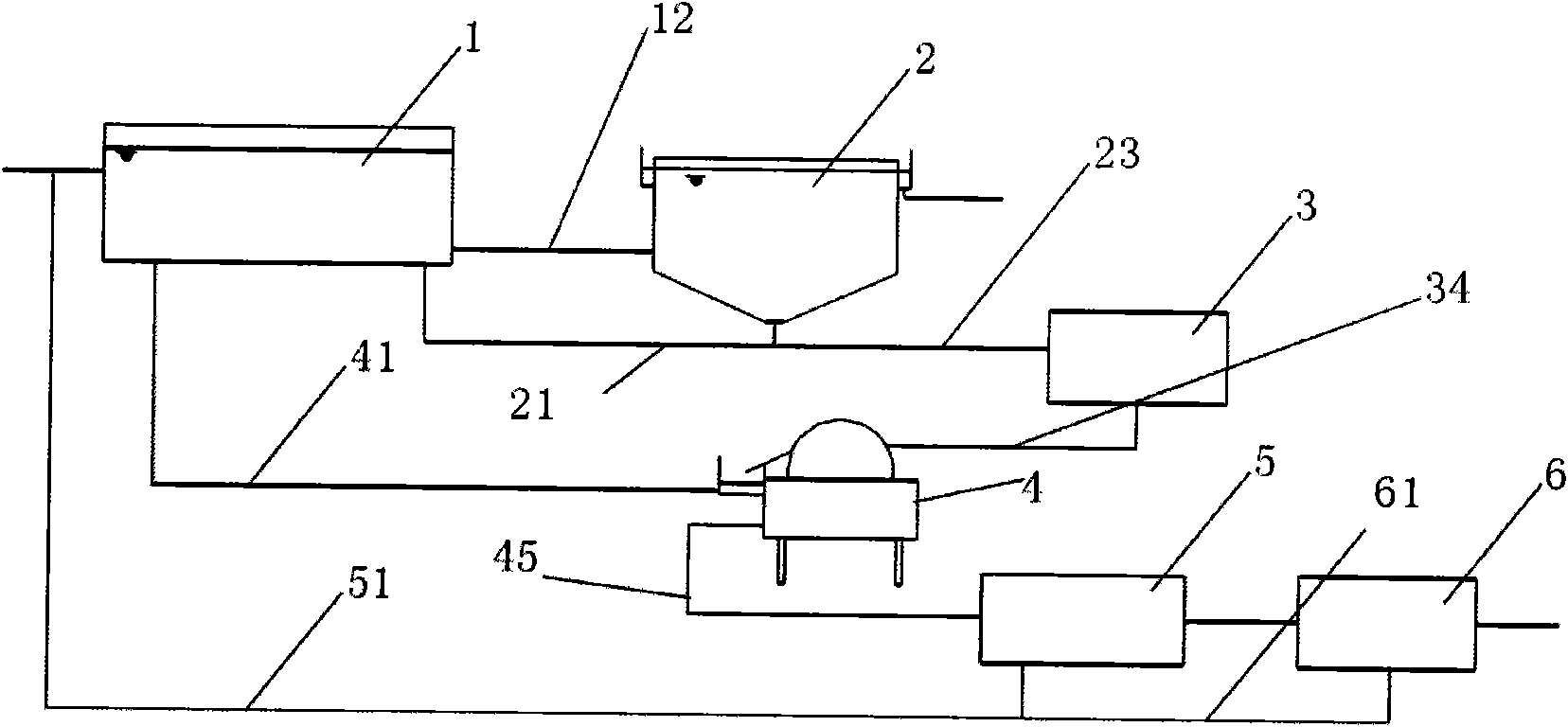

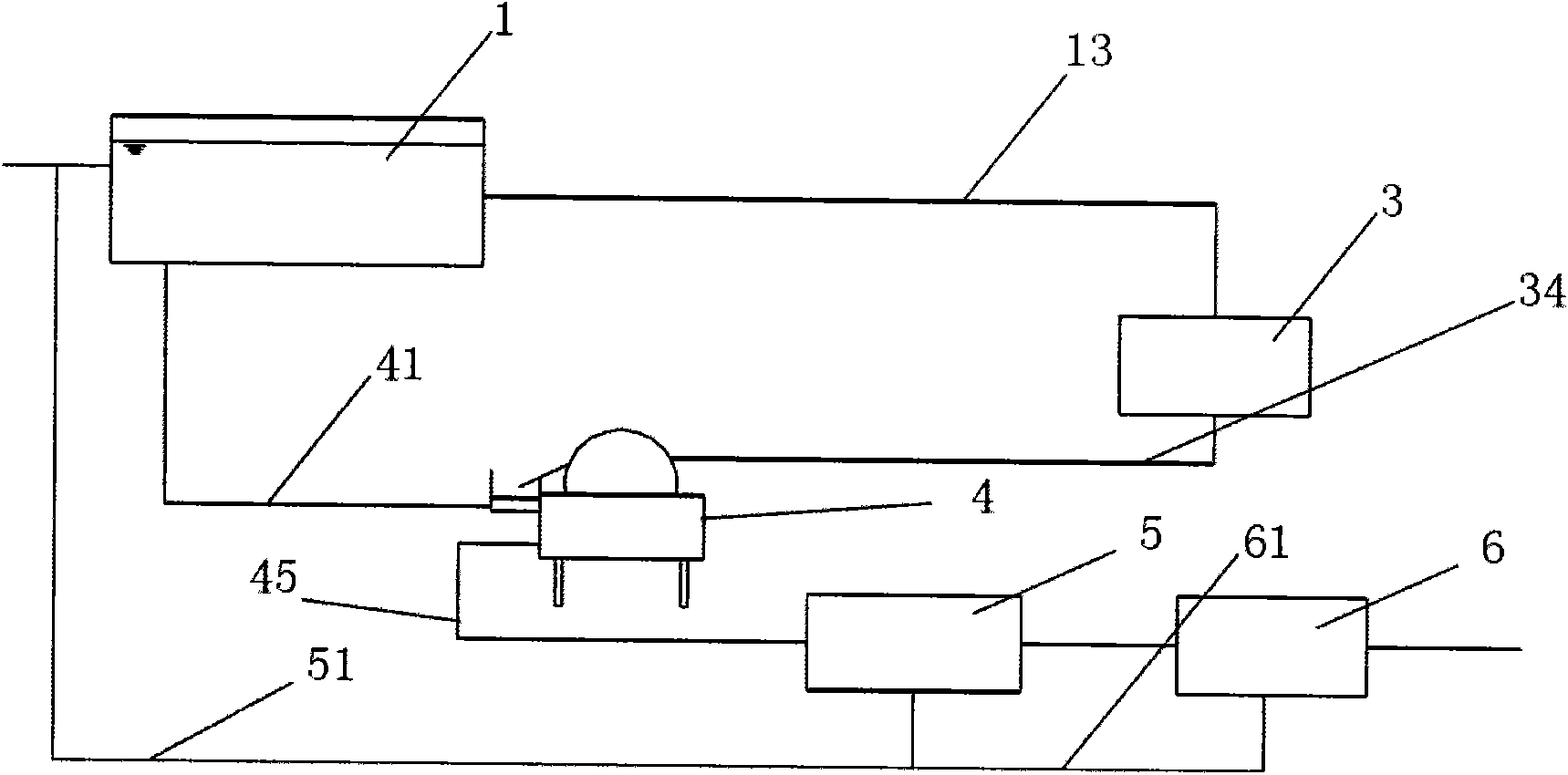

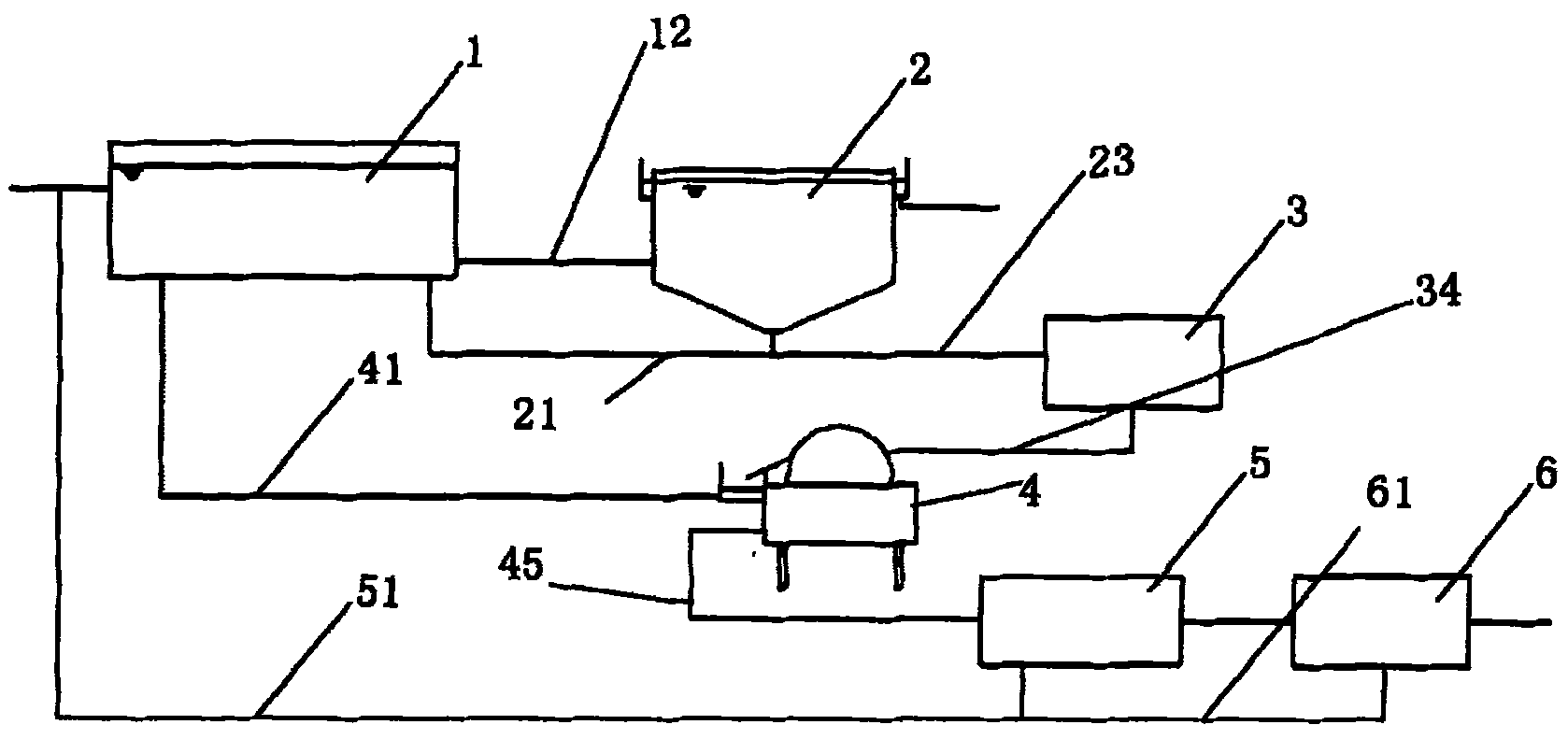

Magnetic carrier containing sewage treatment device and sewage treatment method

A technology for sewage treatment equipment and sewage treatment methods, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problems of easy clogging, accumulation, uneven distribution of air intake, etc. problems, to achieve the effect of low operating costs, convenient maintenance, and reduced infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In a sewage treatment plant, Orbal oxidation ditch is used to treat urban sewage. The average influent COD is 563mg / L, and the influent NH 4 + -N average is 26.3mg / L, the density is 1.0g / cm 3 , The magnetic carrier with a particle size of 0.076-0.16mm was added to the oxidation ditch mixture at 10g / L. After a period of stable operation, the average effluent COD reached 41.7mg / L, the removal rate was 92.6%, and the effluent NH 4 + The average -N reached 0.82mg / L, and the removal rate was 96.9%.

Embodiment 2

[0057] In a sewage treatment plant, Carrousel 2000 oxidation ditch was used to treat urban sewage. The average influent COD was 461mg / L, and the influent BOD 5 Average is 135mg / L, influent NH 4 + -N average is 24.9mg / L, the density is 1.1g / cm 3 , The magnetic carrier with a particle size of 0.076-0.16mm is added to the oxidation ditch mixture at 5g / L. After a period of stable operation, the average COD of the effluent reaches 44.9mg / L, the removal rate is 90.3%, and the BOD of the effluent is 90.3%. 5 The average reached 8.07mg / L, the removal rate was 94.0%, and the effluent NH 4 + The average -N reached 0.91mg / L, and the removal rate was 96.3%.

Embodiment 3

[0059] In a sewage treatment plant, the SBR process was used to treat the brewing wastewater. The average influent COD was 2700mg / L, and the influent BOD 5 The average is 2000mg / L, and the average influent SS is 310mg / L. The wastewater enters the SBR reaction tank after passing through the first-level enhanced sewage treatment process such as fine grids and fiber filters. The density will be 1.1g / cm 3 , The magnetic carrier with a particle size of 0.076-0.16mm is added to the SBR tank mixture at 5g / L. After a period of stable operation, the average COD of the effluent reaches 89.9mg / L, the removal rate is 96.7%, and the BOD of the effluent is 96.7%. 5 The average reached 26.7mg / L, the removal rate was 98.7%, the average SS in the effluent reached 24.1mg / L, and the removal rate was 92.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com