Method for electroplating nano composite plated layer

A nano-composite and coating technology, which is applied in coatings, electrolytic coatings, electrolytic processes, etc., can solve the problems of nano-particle agglomeration and achieve the effects of fine and uniform grain size, convenient promotion and application, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Electroplating nickel-based Nd on stainless steel cathode substrate 2 o 3 Nanocomposite coatings are used as an example to illustrate.

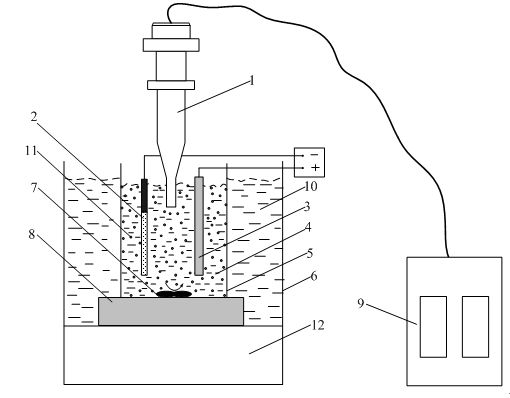

[0039] Such as figure 1 Shown the present invention prepares the electroplating method of nanocomposite coating: will be added with Nd 2 o 3 The plating solution 4 of the nanoparticles 11 is placed in a dual-frequency ultrasonic field under the joint action of bath-type and probe-type ultrasonic waves, and the plating solution 4 is mechanically stirred to perform electroplating on the cathode 2 at the same time.

[0040] The specific steps of the electroplating method are as follows:

[0041] 1) Prepare the plating solution 4:

[0042] The basic plating solution used in the test consists of: nickel sulfate (NiSO 4 ·6H 2 O) 300g / L, boric acid (H 3 BO 3 ) 35g / L, ammonium chloride (NH 4 Cl) 20g / L, wetting agent (C 12 h 25 SO 4 Na) 0.5g / L, neodymium oxide (Nd 2 o 3 ) The nanoparticle diameter is 45nm, the addition amount i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com