Method for preparing polyaniline nano thread

A technology of nanowires and polyaniline, applied in the field of polymer materials, can solve the problems of low concentration, low cost, and large amount of organic solvents, and achieve the effects of mild reaction conditions, reduced dosage, and reduced chances of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

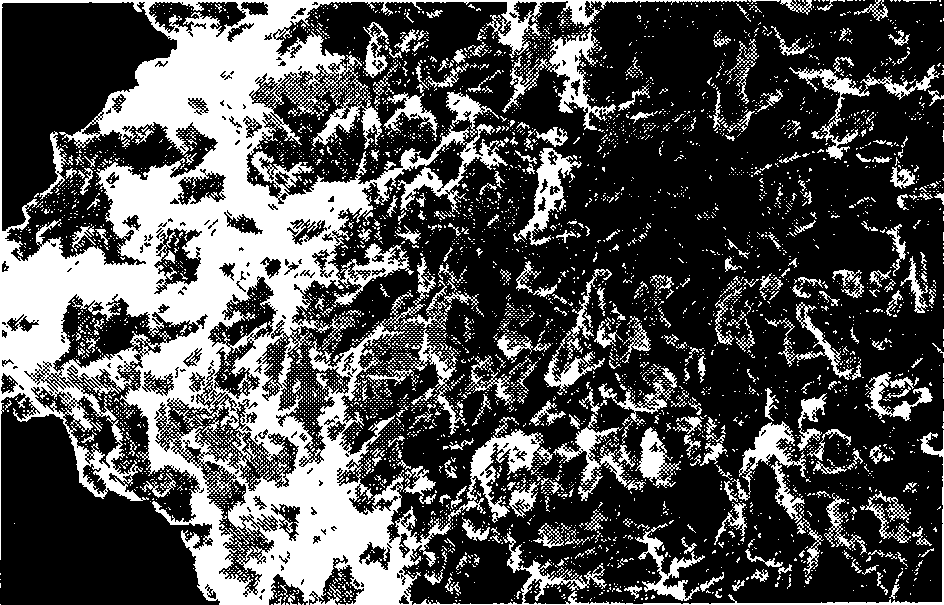

Image

Examples

Embodiment 1

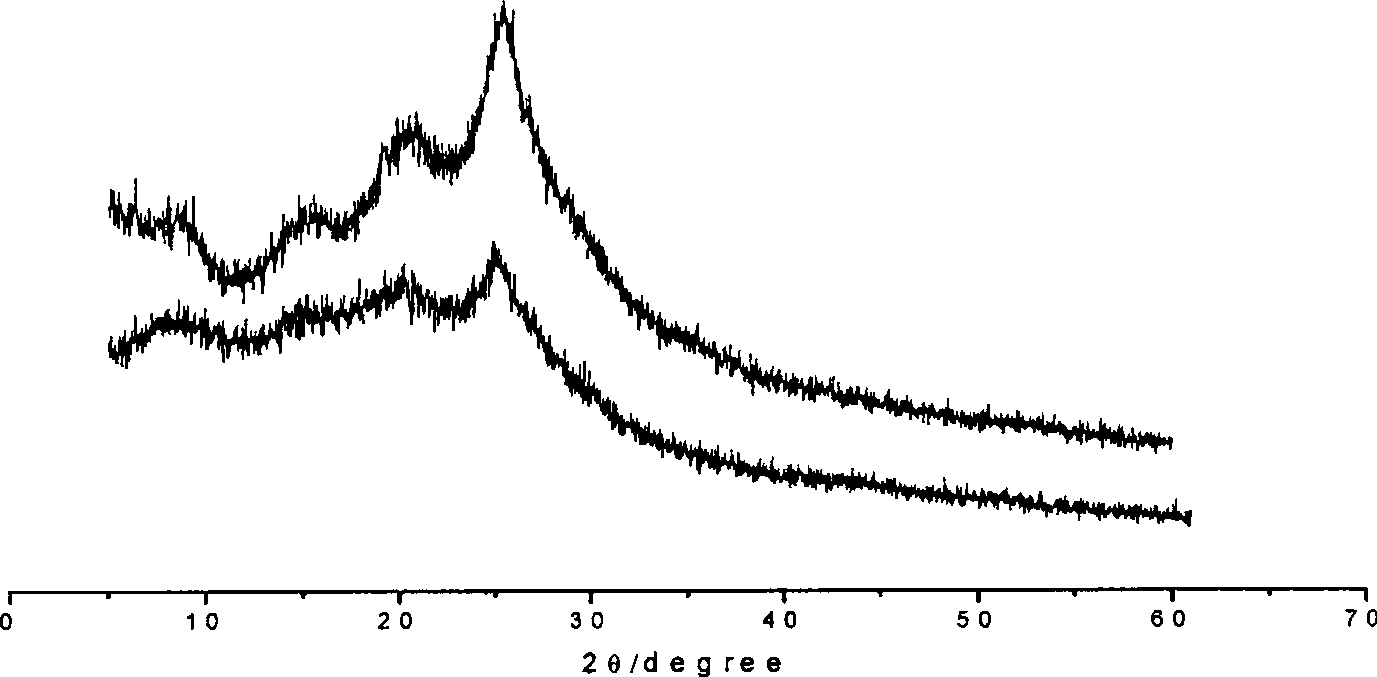

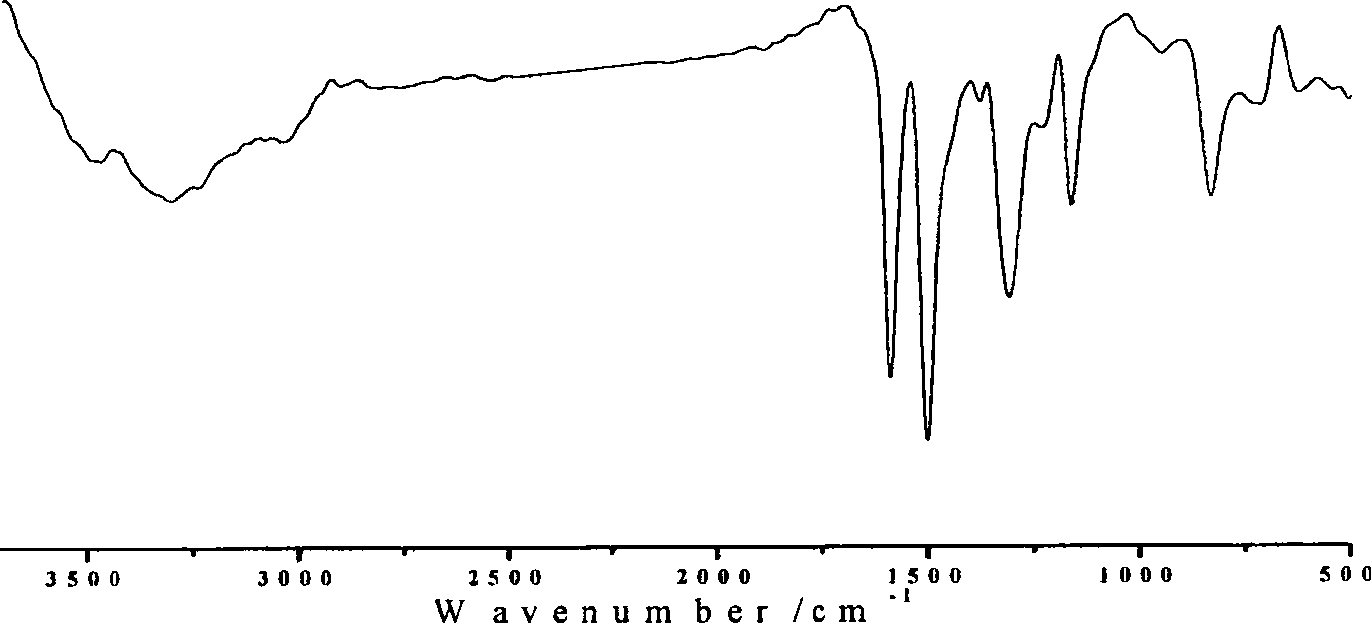

[0020] Embodiment 1: 1. Add 90 ml of 1 mol / L hydrochloric acid aqueous solution and 2 g of 10% polyvinyl alcohol solution in a pre-dissolved mass fraction in a three-necked flask, and stir for 20 min. 2. Add 0.96g of aniline monomer into 5ml of carbon tetrachloride under ice-bath conditions and stir to make it a uniform solution. 3. The carbon tetrachloride solution of aniline is dripped into the water phase prepared in step 1 under stirring with a dropping funnel, and the solution is dripped within 20 minutes, and the reaction is carried out in an ice bath; 4. Add 2.28 g of ammonium persulfate to Add 10ml of hydrochloric acid aqueous solution with a concentration of 1mol / L to make a solution. And the solution was added dropwise to the solution in step 3, and the oxidant solution was added within 40 minutes; 5. After 4 hours of reaction, the product was filtered with suction. Wash with distilled water until the filtrate is neutral, and continue to wash with alcohol until the ...

Embodiment 2

[0022] Example 2: 1. Add 90 ml of 1 mol / L hydrochloric acid aqueous solution into a three-necked flask, add 2 g of a 5% polyvinylpyrrolidone solution that has been dissolved in advance, and stir for 20 min. 2. Add 0.96g of aniline monomer into 5ml of carbon tetrachloride under ice bath conditions, and stir to make it a uniform solution. 3. Use a dropping funnel to add the carbon tetrachloride solution of aniline in step 2 dropwise to the water phase of step 1 under stirring. The solution is added dropwise within 20 minutes, and the reaction is carried out in an ice bath; 4. 2.28g Potassium dichromate was added to 10ml of aqueous hydrochloric acid solution with a concentration of 1mol / L to form a solution. And the solution was added dropwise to the solution in step 3, and the oxidant solution was added within 40 minutes; 5. After reacting for 8 hours, the product was suction-filtered. Wash with distilled water until the filtrate is neutral, and continue to wash with alcohol un...

Embodiment 3

[0023]Embodiment 3: 1. Add 90 ml of 1 mol / L sulfuric acid aqueous solution in a three-necked flask, add 2 g of a 10% polyvinyl alcohol solution with a mass fraction dissolved in advance, and stir vigorously for 20 min. 2. Add 0.96 g of aniline monomer into 5 ml of cyclohexane under the condition of ice bath, and stir to form a uniform solution. 3. Use a dropping funnel to add the cyclohexane solution of aniline in step 2 to the water phase under stirring. The solution is added dropwise within 20 minutes, and the reaction process is carried out in an ice bath; 4. Add 2.28 g of persulfuric acid Ammonium was added to 10ml of sulfuric acid aqueous solution with a concentration of 1mol / L to form a solution. And the solution was added dropwise to the solution in step 3, and the oxidant solution was added within 40 minutes; 5. After 24 hours of reaction, the product was filtered with suction. Wash with distilled water until the filtrate is neutral, and continue to wash with alcohol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com