Preparation method for g-C3N4/CuO composite material

A composite material, g-c3n4 technology, applied in the field of preparation of g-C3N4/CuO composite material, can solve the problems of high calcination temperature and high experimental requirements, and achieve the effects of fast reaction speed, high preparation efficiency and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Such as Figure 5 As shown, a g-C for catalytic decomposition of ammonium perchlorate 3 N 4 / CuO composite material preparation method, including the following steps: put 0.05 g nano-CuO into 20 ml ethanol solution for ultrasonic dispersion for 10 min, stir continuously during the ultrasonic process, and then add 0.95 g of g-C 3 N 4 Continue to ultrasonically disperse for 10 min, stir continuously during the ultrasonic process, grind it in an agate mortar for 30 min until it becomes a paste, dry it in a vacuum oven at 40 °C, and calcinate it in a tube furnace at 100 °C for 120 min to obtain g-C 3 N 4 / CuO composites.

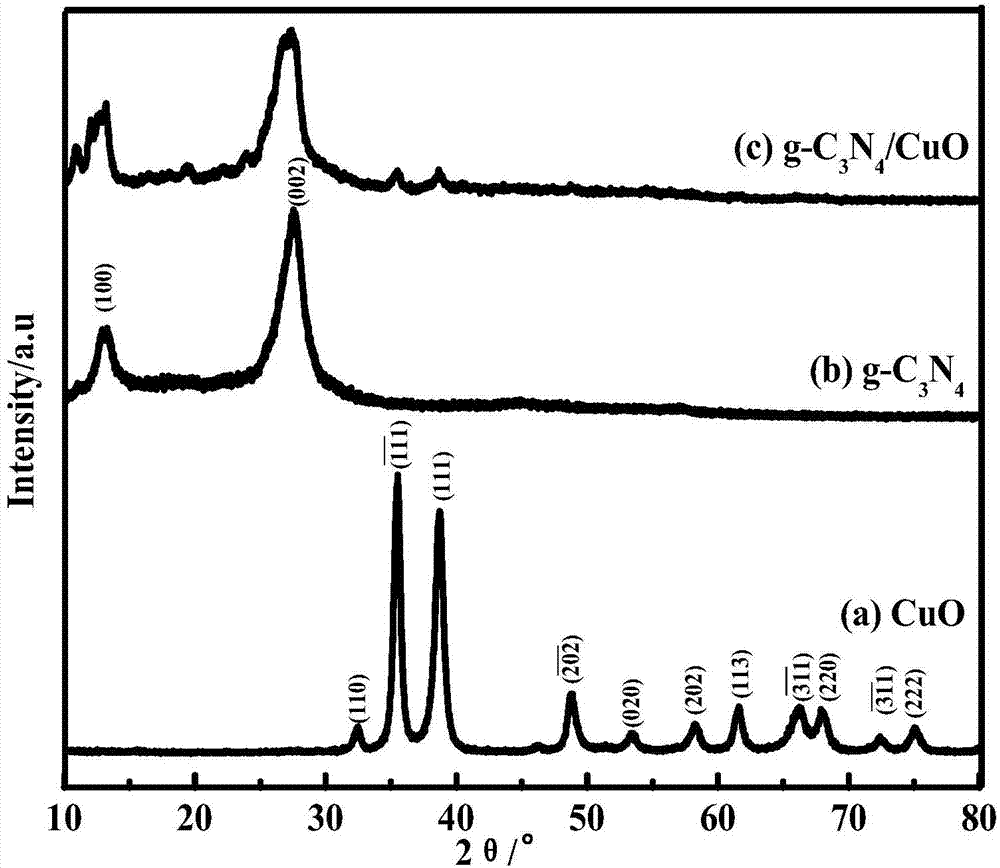

[0024] g-C prepared by Example 1 3 N 4 / CuO composites scanned by X-ray diffractometer, see figure 1 , g-C 3 N 4 g-C can be clearly seen in the XRD curve of / CuO 3 N 4 The characteristic diffraction peaks of CuO, while the diffraction peaks of CuO are weaker, which is due to the g-C 3 N 4 The content of CuO in the / CuO composite is only 5...

Embodiment 2

[0026] Such as Figure 5 As shown, a g-C for catalytic decomposition of ammonium perchlorate 3 N 4 / CuO composite material preparation method, including the following steps: put 0.1 g nano-CuO into 20 ml ethanol solution for ultrasonic dispersion for 30 min, stir continuously during the ultrasonic process, and then add 0.9 g of g-C 3 N 4 Continue to ultrasonically disperse for 30 min, stir continuously during the ultrasonic process, grind it in an agate mortar for 40 min to a paste, put it in a vacuum oven for drying at 60 °C, and calcinate in a tube furnace at 200 °C for 90 min to obtain g-C 3 N 4 / CuO composites.

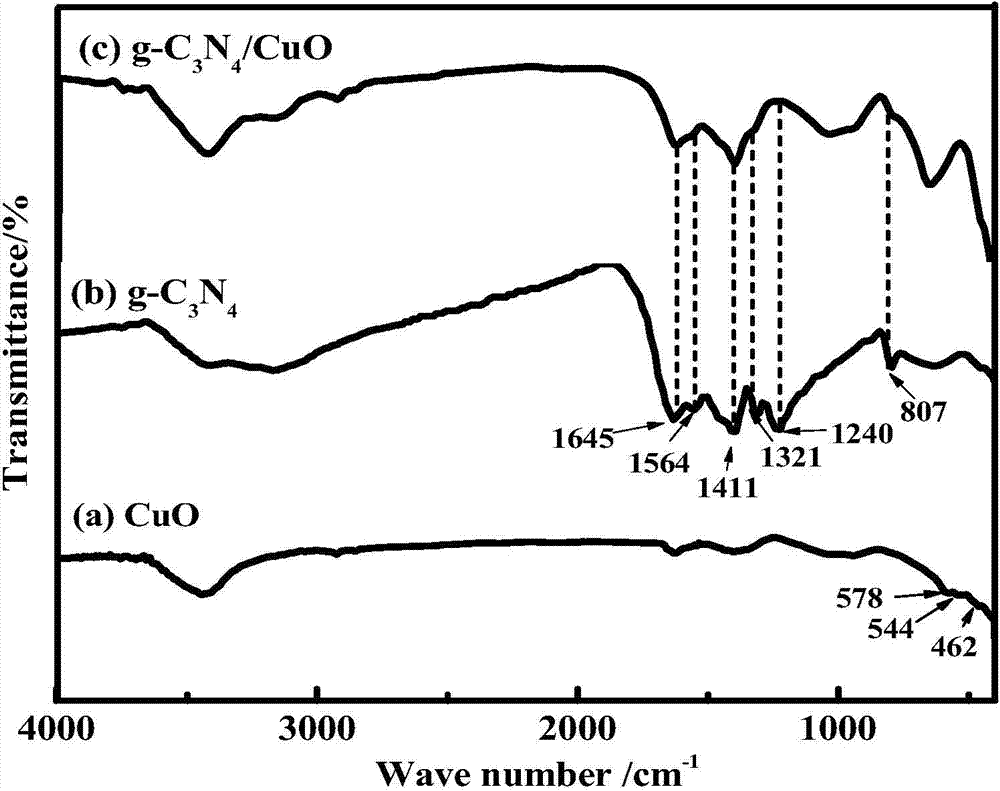

[0027] g-C prepared by Example 2 3 N 4 / CuO composite Fourier transform infrared transform spectrum, see figure 2 , as can be seen from the figure, 1645cm -1 、1240cm -1 、1321cm -1 、1411cm -1 、1564cm -1 、807cm -1 for g-C 3 N 4 Infrared absorption characteristic peak; 578cm -1 、544cm -1 and 462cm -1 is the infrared absorption characteristic pea...

Embodiment 3

[0030] Such as Figure 5 As shown, a g-C for catalytic decomposition of ammonium perchlorate 3 N 4 / CuO composite material preparation method, including the following steps: put 0.2 g nano-CuO into 20 ml ethanol solution for ultrasonic dispersion for 60 min, stir continuously during the ultrasonic process, and then add 0.8 g of g-C 3 N 4 Continue to ultrasonically disperse for 60 min, stir continuously during the ultrasonic process, and grind it in an agate mortar for 60 min until it becomes a paste, put it in a vacuum oven and dry it at 70 °C, and then calcinate it in a tube furnace at 400 °C for 60 min to obtain g-C 3 N 4 / CuO composites.

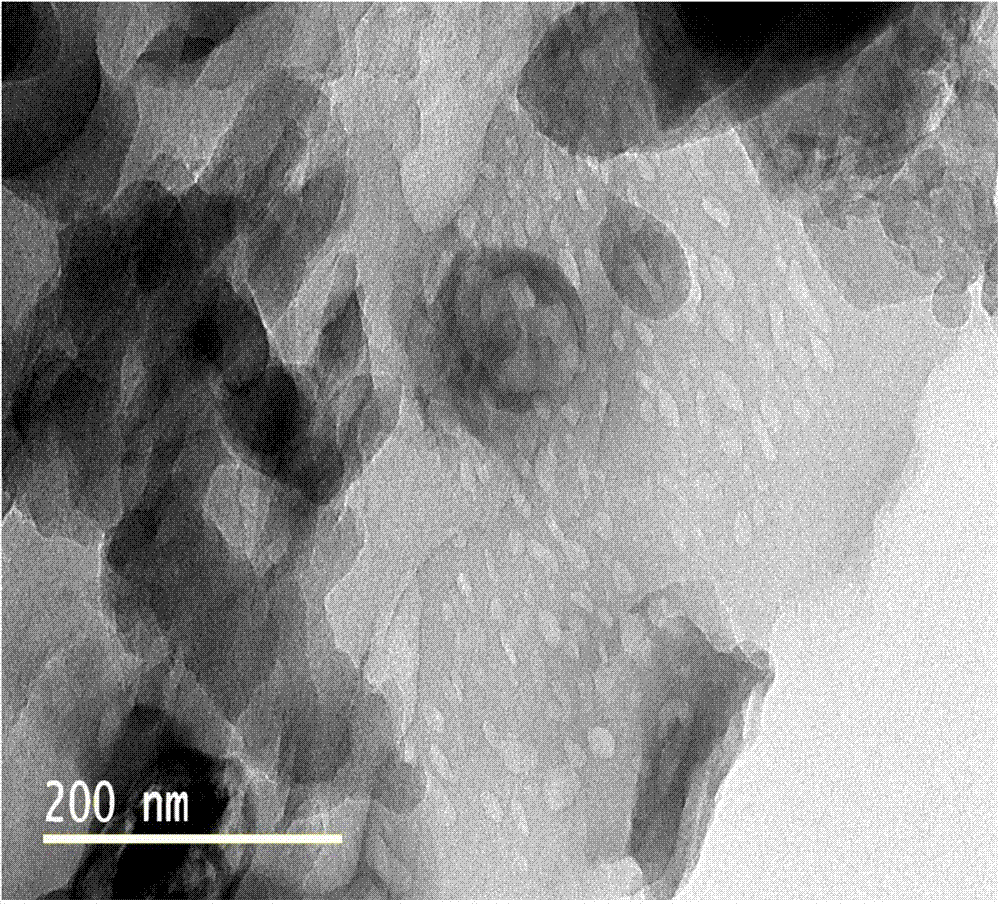

[0031] g-C prepared by Example 3 3 N 4 / CuO composites observed by transmission electron microscopy, see image 3 , CuO deposition dispersed on g-C 3 N 4 A heterojunction structure is formed on the surface.

[0032] Prepared g-C 3 N 4 The performance test of / CuO composite material is as follows: get the g-C that embodiment 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com