Antistatic graphene-coated aluminum microsphere modified PP composite material and preparation method thereof

A graphene coating and composite material technology, applied in the field of antistatic PP composite materials, can solve the problems of unsatisfactory antistatic effect of antistatic PP composite materials, limited application scope of materials, insufficient strength, etc., and achieve excellent antistatic properties. effect, the effect of improving antistatic effect and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

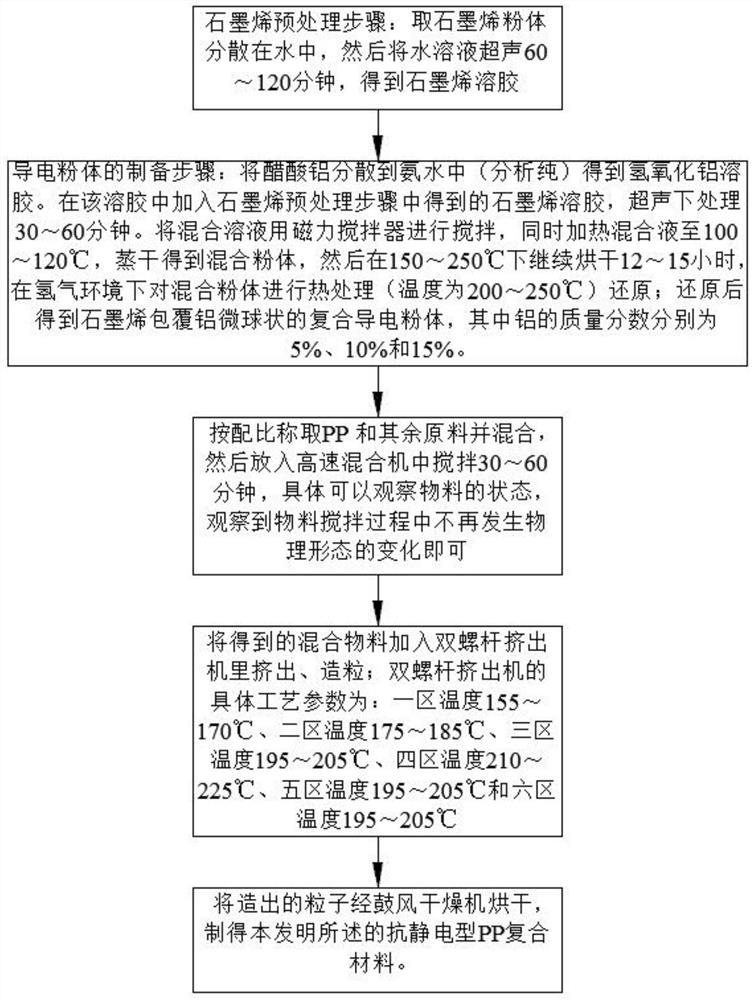

Method used

Image

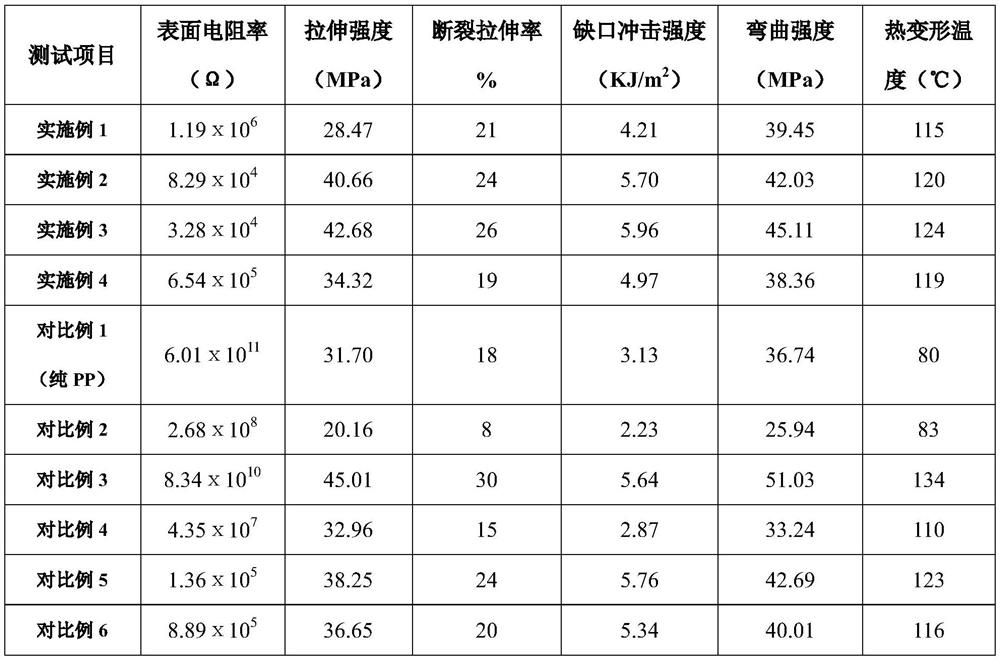

Examples

Embodiment 1

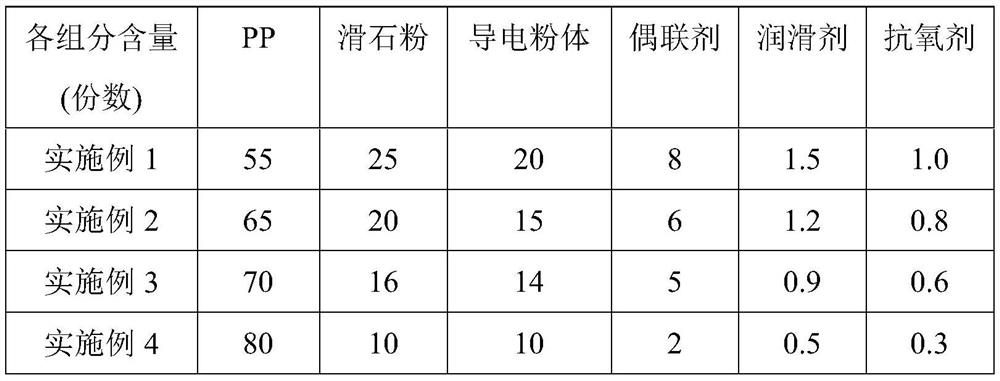

[0033] This embodiment provides an antistatic graphene-coated aluminum microsphere modified PP composite material, including the following raw materials in parts by weight: PP: 55 parts; talcum powder: 25 parts; conductive powder: 20 parts; coupling agent : 8 parts; Lubricant: 1.5 parts; Antioxidant: 1.0 parts.

[0034] Wherein, the conductive powder is a mixed powder of graphene-coated aluminum microspheres prepared by a typical molecular-level mixing method, and the mass fraction of aluminum is 10%.

[0035] Further, the preparation method of the conductive powder is as follows: graphene pretreatment: take the graphene powder, disperse it in water, and then ultrasonicate the aqueous solution for 120 minutes to obtain a graphene sol;

[0036] Preparation of conductive powder of graphene-coated aluminum microspheres: disperse aluminum acetate in ammonia water (analytical pure) to obtain aluminum hydroxide sol; add the graphene sol obtained in step (1) to the sol, and process i...

Embodiment 2

[0046] This embodiment provides an antistatic material of graphene-coated aluminum microspheres modified PP, including the following raw materials in parts by weight: PP: 65 parts; talcum powder: 20 parts; conductive powder: 15 parts; coupling agent: 6 parts; lubricant: 1.2 parts; antioxidant: 0.8 parts.

[0047] Wherein, the conductive powder is a mixed powder of graphene-coated aluminum microspheres prepared by a typical molecular-level mixing method, and the mass fraction of aluminum is 10%.

[0048] Further, the preparation method of the conductive powder is as follows: graphene pretreatment: take the graphene powder, disperse it in water, and then ultrasonicate the aqueous solution for 120 minutes to obtain a graphene sol;

[0049] Preparation of conductive powder of graphene-coated aluminum microspheres: disperse aluminum acetate in ammonia water (analytical pure) to obtain aluminum hydroxide sol; add the graphene sol obtained in step (1) to the sol, and process it under...

Embodiment 3

[0059] This embodiment provides an antistatic material of graphene-coated aluminum microspheres modified PP, including the following raw materials in parts by weight: PP: 70 parts; talcum powder: 16 parts; conductive powder: 14 parts; coupling agent: 5 parts; lubricant: 0.9 parts; antioxidant: 0.6 parts.

[0060] Wherein, the conductive powder is a mixed powder of graphene-coated aluminum microspheres prepared by a typical molecular-level mixing method, and the mass fraction of aluminum is 10%.

[0061] Further, the preparation method of the conductive powder is as follows: graphene pretreatment: take the graphene powder, disperse it in water, and then ultrasonicate the aqueous solution for 120 minutes to obtain a graphene sol;

[0062] Preparation of conductive powder of graphene-coated aluminum microspheres: disperse aluminum acetate in ammoniacal liquor (analytical pure) to obtain aluminum hydroxide sol; add the graphene sol that step (1) obtains to this sol, process 50 und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com