Preparation method of elemental-copper-coated crystal whisker carbon nanotube/magnesium-based composite semisolid-state blank

A technology of carbon nanotubes and composite materials, applied in the field of material preparation, to achieve the effects of low risk factor, low reaction temperature and good interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

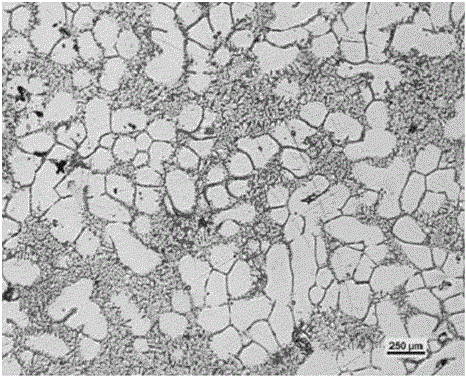

Image

Examples

Embodiment 1

[0035] Whiskered carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C. After cooling to room temperature, they were washed with deionized water, centrifuged until neutral, and dried in a vacuum oven for later use. Copper nitrate and the above-mentioned dried whisker carbon nanotubes are used as raw materials, and added to pure ethanol for 40 minutes of ultrasonication; wherein the molar ratio of whisker carbon nanotubes, copper nitrate and ethanol is 1:0.4:127, and the suspension of whisker carbon nanotubes is obtained. liquid; the suspension is introduced into the hydrothermal reaction kettle, wherein the volume of the suspension accounts for 25% of the volume of the reaction kettle. Then put it into the reaction furnace to heat, raise the temperature to 200°C at 3°C / min, keep it for 2 hours, then raise the temperature to 300°C at 3°C / min, and keep it for 8 hours; seal and cool to room temperature, filter and dry at low temperatur...

Embodiment 2

[0038] Whisker carbon nanotube-walled carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C, cooled to room temperature, washed with deionized water, centrifuged until neutral, and then dried in a vacuum oven for use. Copper nitrate and the above-mentioned dried whisker carbon nanotubes are used as raw materials, and added to pure ethanol for 50 minutes of ultrasonication; wherein the molar ratio of whisker carbon nanotubes, copper nitrate and ethanol is 1:0.6:127, and the suspension of whisker carbon nanotubes is obtained. liquid; the suspension is introduced into the hydrothermal reaction kettle, wherein the volume of the suspension accounts for 25% of the volume of the reaction kettle. Then put it into the reaction furnace to heat, raise the temperature to 200°C at 5°C / min, keep it warm for 1h, then raise the temperature to 300°C at 3°C / min, keep it warm for 8h; seal and cool to room temperature, filter and dry at low temperature...

Embodiment 3

[0041] Whiskered carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C. After cooling to room temperature, they were washed with deionized water, centrifuged until neutral, and dried in a vacuum oven for later use. Copper nitrate and the above-mentioned dried carbon nanotubes were used as raw materials, and were added into pure ethanol for ultrasonication for 60 minutes; wherein the molar ratio of whisker carbon nanotubes, copper nitrate and ethanol was 1:0.8:127 to obtain whisker carbon nanotube suspensions; The suspension is introduced into a hydrothermal reaction kettle, wherein the volume of the suspension accounts for 25% of the volume of the reaction kettle. Then put it into the reaction furnace to heat, raise the temperature to 200°C at 3°C / min, keep it for 1h, then raise the temperature to 300°C at 3°C / min, keep it for 10h; seal and cool to room temperature, filter and dry at low temperature, then put it into a corundum cruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com