Self-insulating wall ceramsite concrete and preparation method thereof

A technology of ceramsite concrete and self-insulation, applied in the field of concrete, can solve the problems of inconsistency between the life of the insulation material and the wall, the increase of its own bulk density, and the decrease of insulation performance, so as to reduce the phenomenon of floating, prevent uneven performance, and improve thermal insulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

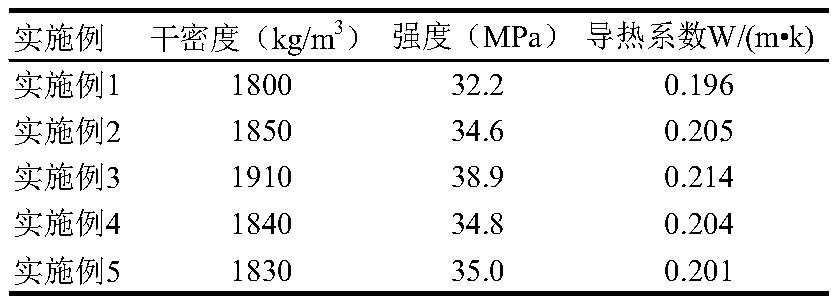

Embodiment 1

[0024] The invention provides a self-insulating wall ceramsite concrete, which comprises the following components in parts by weight: 550 parts of continuously graded silt ceramsite with a particle size of 5-25 mm, 340 parts of ordinary cement with P.O 42.5, and 120 parts of fly ash. 680 parts of sand with a fineness modulus of 2.3-3.0, 132 parts of water, 3 parts of polycarboxylate superplasticizer, 2 parts of polypropylene fiber with a length of 6-12mm and a diameter of 30-40μm; the cylinder pressure of ceramsite The strength is 3.5MPa, the bulk density is 550kg / m 3 , Water absorption rate is 9%, polypropylene fiber density is 0.9-0.93kg / m 3 , breaking strength 400MPa, breaking elongation 27.6%, elastic modulus 4660MPa, polycarboxylate water reducing agent water reducing rate 16%-19%, solid content 14%-15%; The pretreatment slurry is composed of 36.8 parts of P.O 42.5 ordinary cement, 24.5 parts of fly ash and 30.7 parts of water.

[0025] The present invention also provid...

Embodiment 2

[0028] The invention provides a self-insulating wall ceramsite concrete, which includes the following components in parts by weight: 500 parts of continuously graded silt ceramsite with a particle size of 5-25 mm, 340 parts of ordinary cement with P.O 42.5, and 140 parts of fly ash. Parts, 700 parts of sand with a fineness modulus of 2.3-3.0, 136 parts of water, 3 parts of polycarboxylate superplasticizer, 2 parts of polypropylene fiber with a length of 6-12mm and a diameter of 30-40μm; the cylinder pressure of ceramsite Strength is 4.5MPa, bulk density is 600kg / m 3 , Water absorption rate is 9%, polypropylene fiber density is 0.9-0.93kg / m 3 , breaking strength 400MPa, breaking elongation 27.6%, elastic modulus 4660MPa, polycarboxylate water reducing agent water reducing rate 16%-19%, solid content 14%-15%; The pretreatment slurry is composed of 68.8 parts of P.O 42.5 ordinary cement, 39.3 parts of fly ash and 58.9 parts of water.

[0029] The present invention also provides...

Embodiment 3

[0032] The invention provides a self-insulating wall ceramsite concrete, which comprises the following components in parts by weight: 470 parts of continuously graded silt ceramsite with a particle size of 5-25 mm, 360 parts of ordinary cement with P.O 42.5, and 150 parts of fly ash 730 parts of sand with a fineness modulus of 2.3-3.0, 145 parts of water, 3 parts of polycarboxylate superplasticizer, 3 parts of polypropylene fiber with a length of 6-12mm and a diameter of 30-40μm; the cylinder pressure of ceramsite The strength is 3.5MPa, the bulk density is 560kg / m 3 , Water absorption rate is 9%, polypropylene fiber density is 0.9-0.93kg / m 3 , breaking strength 400MPa, breaking elongation 27.6%, elastic modulus 4660MPa, polycarboxylate water reducing agent water reducing rate 16%-19%, solid content 14%-15%; The pretreatment slurry is composed of 84 parts of ordinary cement with P.O 42.5, 67 parts of fly ash and 84 parts of water.

[0033] The present invention also provides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com