A kind of warp knitting machine with floating fiber filter mechanism

A fiber filtration and warp knitting machine technology, applied in the field of warp knitting machines, can solve the problems of workers' health effects, fiber floating, and workers inhaling too many floating fibers, so as to reduce fiber floating and dust floating, and facilitate warp knitting. , increase the effect of lung protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

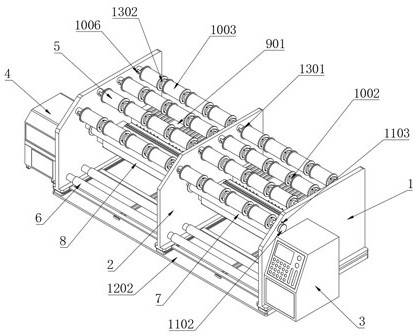

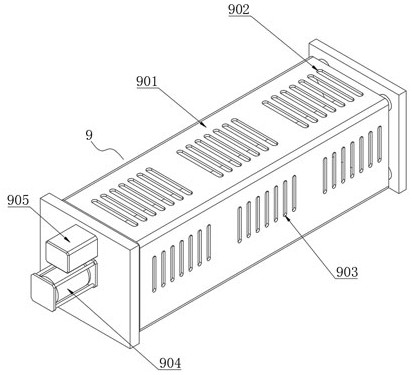

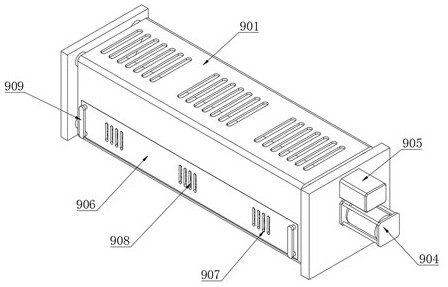

[0043] Example: such as Figure 1-9 As shown, the present invention provides technical scheme, a kind of warp knitting machine, comprises warp knitting frame 1, and the top center of warp knitting frame 1 is equipped with intermediate partition 2, and one end of warp knitting frame 1 is connected with control cabinet 3 , the other end of the warp knitting frame 1 is connected with the equipment cabinet 4, the inner wall of one end of the warp knitting frame 1 is connected with the yarn bundle roller 5, and the inner wall of one end of the warp knitting frame 1 corresponds to the side position of the yarn bundle roller 5 Cloth convergent roller 6 is installed in rotation, one end inner wall of warp knitting frame 1 corresponds to cloth convergent roller 6 and one side position is rotated and installed with guide roller 7, and one end inner wall of warp knitting frame 1 corresponds to cloth convergent roller 6- The jacquard needle 8 is rotated and installed at the side position;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com