Braking system of light truck

A braking system and service braking technology, applied in the direction of brakes, braking components, braking transmission devices, etc., can solve the problem of poor braking efficiency, poor braking thermal stability and water stability, and brake heat dissipation performance. To reduce tire wear, reduce brake deviation, and reduce slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

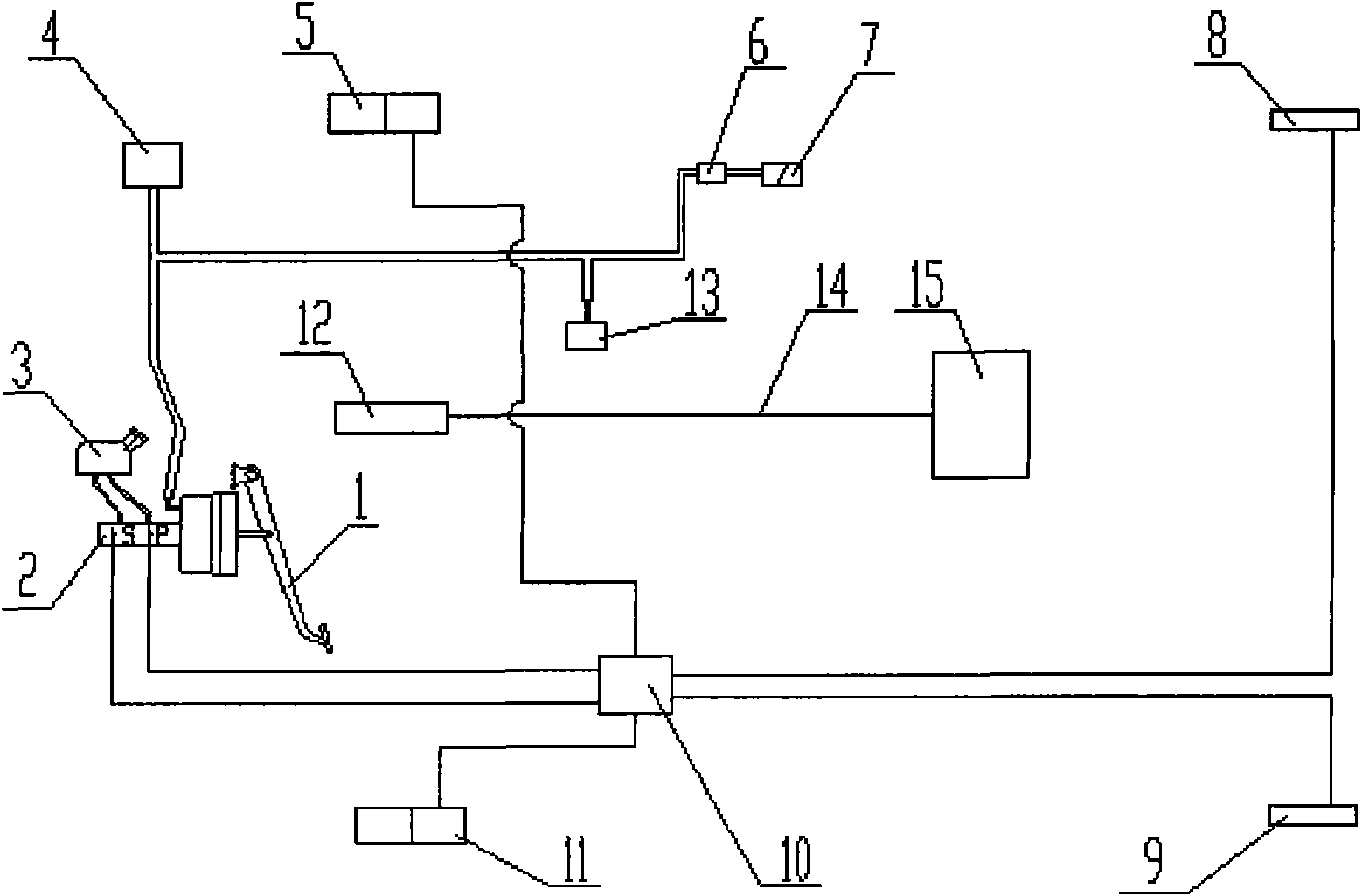

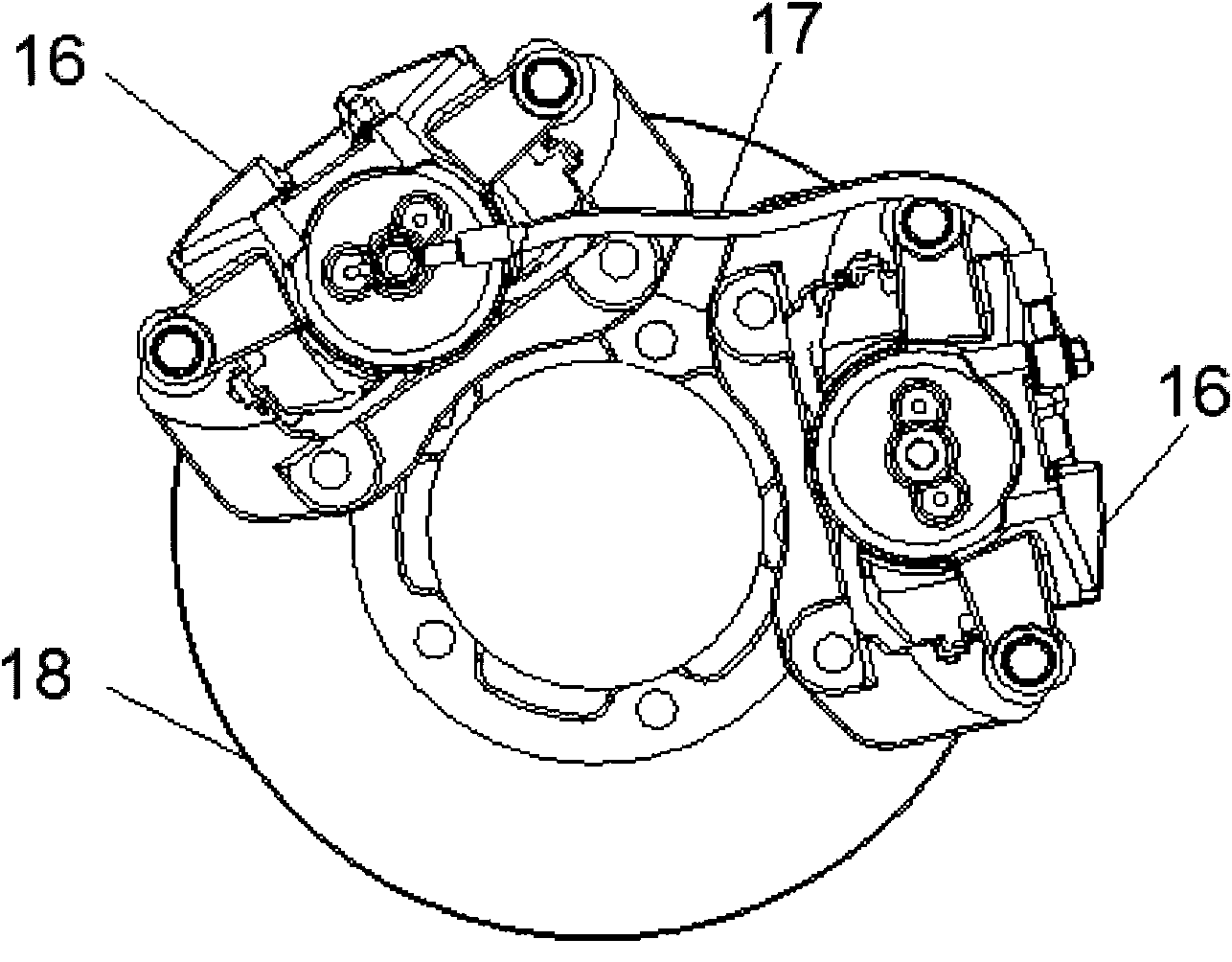

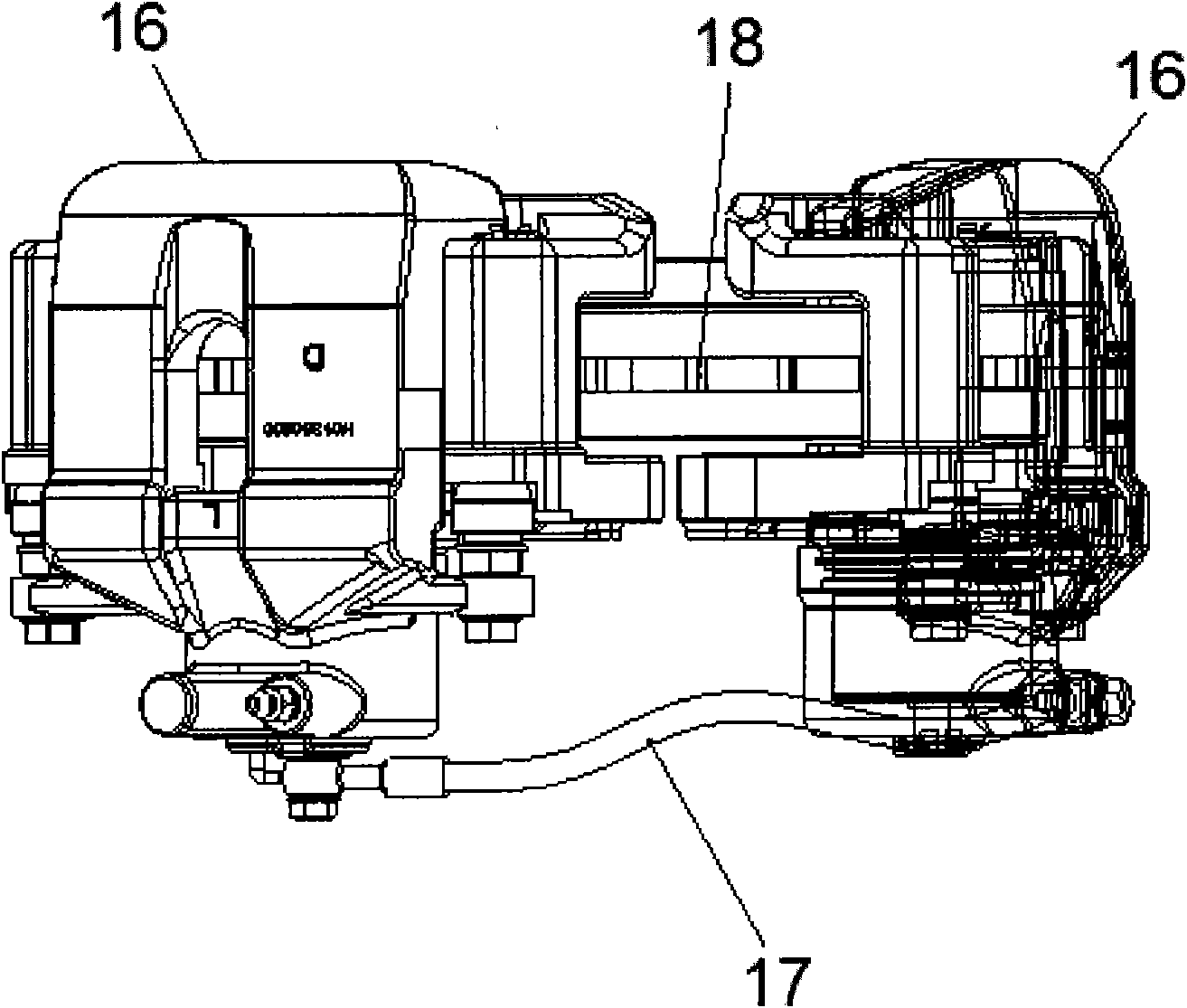

[0029] like figure 1 As shown, the present invention provides a braking system of a light truck, including a service braking unit, a parking braking unit and an exhaust auxiliary braking unit. The service brake unit includes brake pedal assembly 1, vacuum booster and brake master cylinder assembly 2, oil storage cup 3, ABS valve body 10, first front axle brake assembly 5, second front axle brake assembly 11. The first rear axle brake assembly 8 and the second rear axle brake assembly 9. The brake pedal assembly 1 is installed on the body floor, the vacuum booster and brake master cylinder assembly 2 are installed on the brake pedal assembly 1, and the oil storage cup 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com