Silicone sealant for automobile side windscreen and preparation method thereof

A silicone sealant, windshield technology, used in chemical instruments and methods, adhesives, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

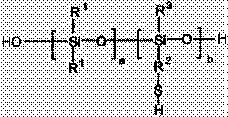

Method used

Image

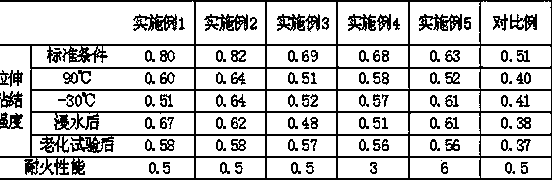

Examples

Embodiment 1

[0070] The silicone sealant of the present embodiment is composed as follows:

[0071] α, ω-dihydroxypolysiloxane 100 parts by weight

[0072] Modified silicon dioxide 60 parts by weight

[0073] Vinyltriethoxysilane 1 part by weight

[0074] Butyl titanate 0.3 parts by weight

[0075] 15 parts by weight of methyl silicone oil

[0076] Modified silicon dioxide is KH550 silane coupling agent and sodium stearate modified silicon dioxide.

[0077] The preparation method of this silicone sealant is:

[0078] 1) Add 100 parts by weight of α, ω-dihydroxy polysiloxane, 60 parts by weight of KH550 coupling agent and sodium stearate modified silicon dioxide into the kneader, and heat Mixing and dehydration at ~0.1MPa for 360 minutes, cooling to obtain the base material;

[0079] 2) Add 1 part by weight of vinyltriethoxysilane, 0.3 part by weight of butyl titanate, and 15 parts by weight of methyl silicone oil into a strong disperser, mix with the above base material, and at room ...

Embodiment 2

[0082] The silicone sealant of the present embodiment is composed as follows:

[0083] α, ω-dihydroxypolysiloxane 100 parts by weight

[0084] Modified silica 10 parts by weight

[0085] Vinyltriethoxysilane 1.5 parts by weight

[0086] Butyl titanate 0.5 parts by weight

[0087] 5 parts by weight of methyl silicone oil

[0088] Modified silicon dioxide is sodium stearate modified silicon dioxide.

[0089] The preparation method of this silicone sealant is:

[0090] 1) Add 100 parts by weight of α, ω-dihydroxypolysiloxane and 10 parts by weight of sodium stearate modified silicon dioxide into the kneader, and mix at 110-140°C and vacuum degree of 0.06-0.1MPa Refining and dehydration for 30 minutes, cooling to obtain the base material;

[0091] 2) Add 1.5 parts by weight of vinyltriethoxysilane, 0.5 parts by weight of butyl titanate, and 5 parts by weight of methyl silicone oil into a strong disperser, mix with the above base material, and at room temperature, the vacuum ...

Embodiment 3

[0094] The silicone sealant of the present embodiment is composed as follows:

[0095] α, ω-dihydroxypolysiloxane 100 parts by weight

[0096] Modified silicon dioxide 60 parts by weight

[0097] Vinyltriethoxysilane 2 parts by weight

[0098] Butyl titanate 0.1 parts by weight

[0099] 20 parts by weight of methyl silicone oil

[0100] Modified silicon dioxide is potassium stearate modified silicon dioxide.

[0101] The preparation method of this silicone sealant is:

[0102] 1) Add 100 parts by weight of α, ω-dihydroxypolysiloxane and 60 parts by weight of potassium stearate modified silicon dioxide into the kneader, and mix at 110-140°C and vacuum degree of 0.06-0.1MPa Refining and dehydration for 120 minutes, cooling to obtain the base material;

[0103] 2) Add 2 parts by weight of vinyltriethoxysilane, 0.1 parts by weight of butyl titanate, and 20 parts by weight of methyl silicone oil into a strong disperser, mix with the above base material, and at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com