Preparation and application of visible light responding CuAl2O4-graphene photocatalyst

A photocatalyst, graphene technology, applied in the preparation of organic compounds, the preparation of hydroxyl compounds, catalysts for physical/chemical processes, etc., can solve the problems of limiting photocatalytic activity, low photocatalytic efficiency, reducing specific surface area, etc. Photocatalytic activity, cheap reagents, reduced effect of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

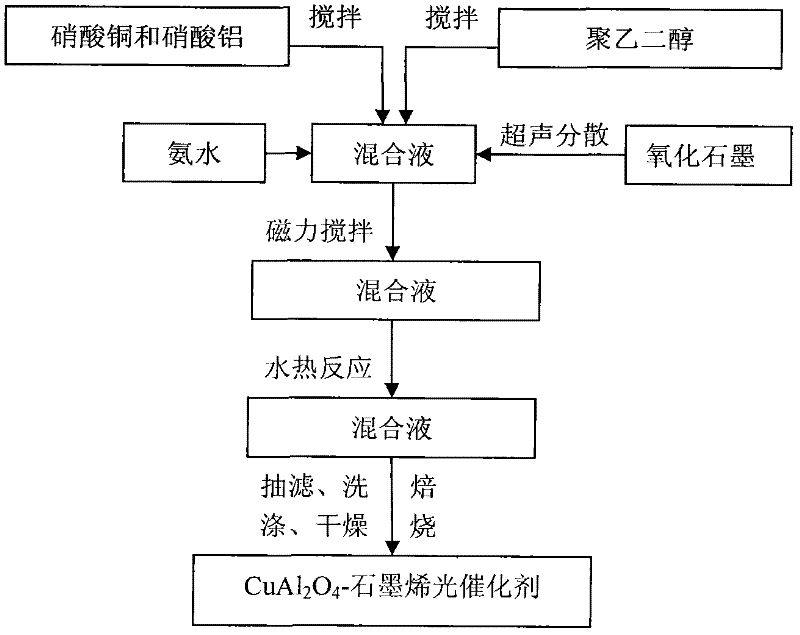

[0020] The present invention responds to a kind of visible light CuAl 2 o 4 -The preparation method of graphene photocatalyst, comprises the following steps:

[0021] (1) Weigh a certain amount of copper nitrate and aluminum nitrate and dissolve them in deionized water, add polyethylene glycol (PEG-4000) as a dispersant, adjust the pH of the solution with 25% ammonia water, stir, and let stand.

[0022] (2) Prepare graphite oxide from graphite powder.

[0023] (3) with CuAl 2 o 4 To measure the quality of graphite oxide, different proportions of graphite oxide were ultrasonically dispersed in reducing alcohol.

[0024] (4) After mixing the reaction system in step (1) with the suspension prepared in step (3), transfer it to a hydrothermal reaction kettle for hydrothermal reaction.

[0025] (5) Pour the product in step (4) into a vacuum filtration device for suction filtration, wash with deionized water, vacuum dry, grind and roast to obtain nano-CuAl 2 o 4 - Graphene pho...

Embodiment 1

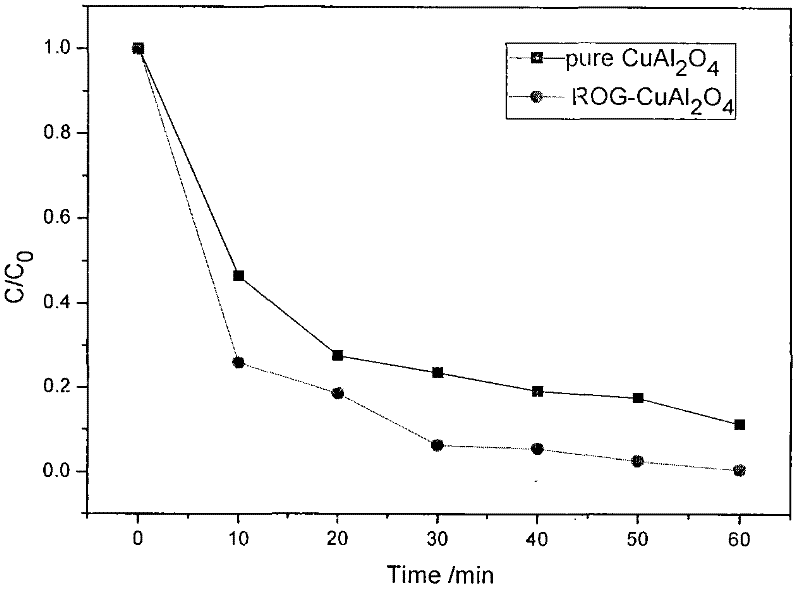

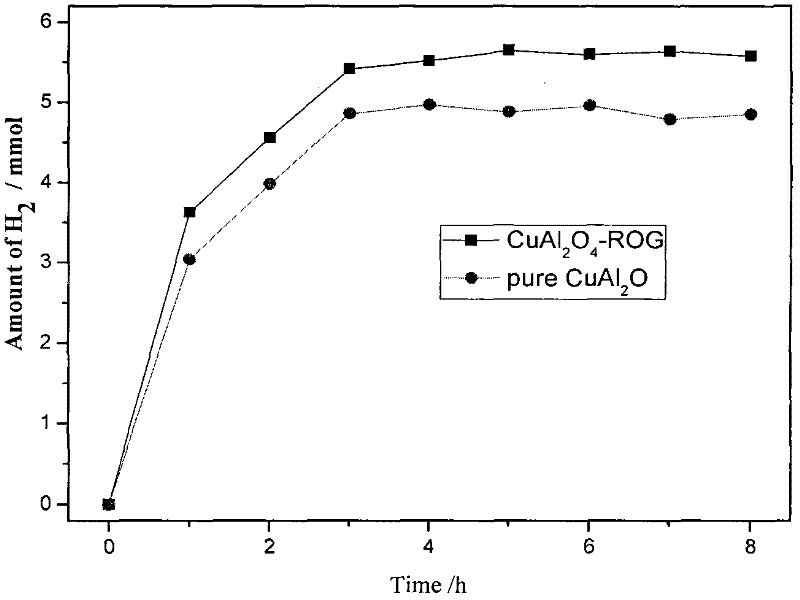

[0035] CuAl prepared under optimal conditions with 1% graphite oxide 2 o 4 - Graphene photocatalyst, when the amount of photocatalyst is 0.5g / L, the degradation rate of methyl orange with a concentration of 25mg / L is 85.26% after 60min, continuous hydrogen production is 6h, and the average hydrogen production rate is 3.1mmol / gcat·h. Under the same conditions, the degradation rate of the control experiment in the dark is less than 5%, and there is no hydrogen production effect. The blank experiment without catalyst has almost no degradation and hydrogen production effect after 60 minutes of light irradiation.

[0036] Preparation method embodiment 2

[0037] CuAl prepared under optimum conditions with an amount of 2% graphite oxide 2 o 4 - Graphene photocatalyst, when the amount of photocatalyst is 0.8g / L, the degradation rate of methyl orange with a concentration of 25mg / L reaches 98.25% after 60min, continuous hydrogen production for 6h, and the average hydrogen productio...

Embodiment 3

[0039] CuAl prepared under optimal conditions with an amount of 3% graphite oxide 2 o 4 - Graphene photocatalyst, when the concentration is 1.0g / L, the degradation rate of methyl orange with a concentration of 25mg / L is 95.52% after 60min, continuous hydrogen production for 6h, and the average hydrogen production rate is 4.7mmol / gcat·h. Under the same conditions, the degradation rate of the control experiment in the dark is less than 7%, and there is no hydrogen production effect. There is almost no degradation and hydrogen production effect in the blank experiment without catalyst after 60 minutes of light irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com